Method for selectively removing monosaccharides and producing oligosaccharides by using yeast culture

A yeast culture and oligosaccharide technology, applied in the field of bioengineering, can solve the problems of difficult large-scale production, poor separation selectivity, and high calorie consumption, and achieve the effect of overcoming poor separation selectivity, large differences in physical properties, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

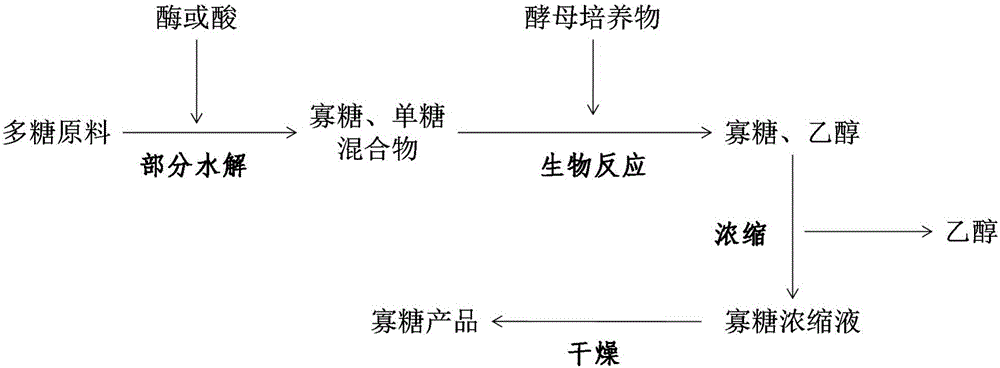

Method used

Image

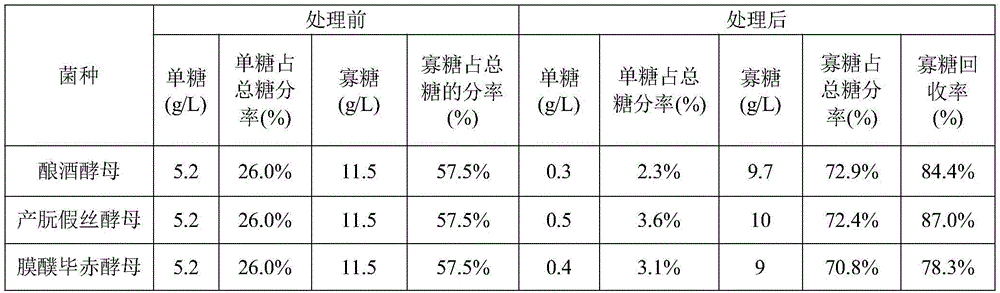

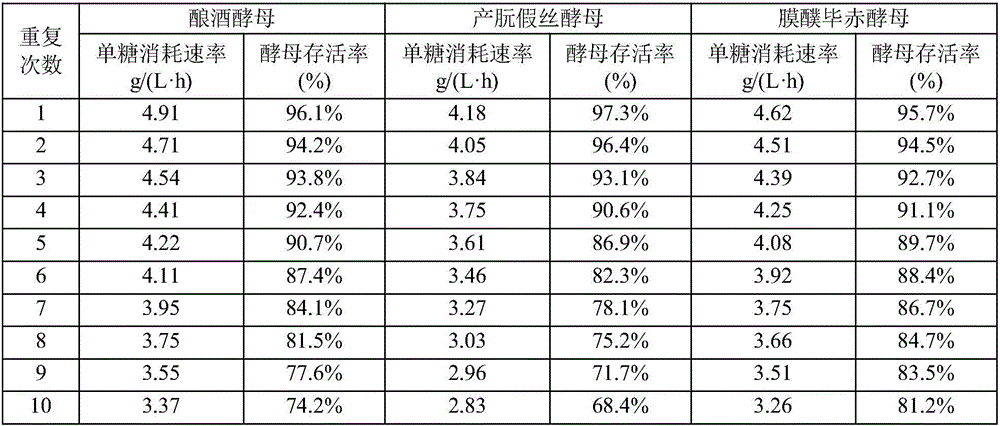

Examples

Embodiment 1

[0035] Embodiment 1: the acid hydrolysis process of thermogelling polysaccharide

[0036] Thermogel is insoluble in water, but soluble in alkaline solution. Weigh 20g hot gel powder and dissolve in 1000mL1.0mol L -1 In the NaOH solution, stir magnetically for 3-4h until it is fully dissolved. Slowly add 5mol·L -1 The HCl solution is neutralized to neutral, and the neutralization solution is at 8000r·min -1 Centrifuge for 10 min, and wash the precipitate with water 2-3 times. Resuspend the precipitate in 80°C hot water, add concentrated hydrochloric acid to a final concentration of 0.5mol L -1 , stirred and reacted at 80° C. for 60 min, added NaOH solution to neutralize to neutral, cooled the reaction liquid to room temperature, and obtained the partial hydrolyzate of curdlan.

Embodiment 2

[0037] Embodiment 2: the acid hydrolysis process of gellan gum polysaccharide

[0038] Prepare 1000mL of 20g / L gellan gum polysaccharide solution, the reaction temperature is 70°C, add H 2 SO 4 solution to a final concentration of 0.5 mol L -1 , hydrolyzed at a constant temperature for 4 hours under stirring conditions, and then neutralized to neutral with NaOH solution to obtain a partial hydrolyzate of gellan gum polysaccharide.

Embodiment 3

[0039] Embodiment 3: the enzymatic hydrolysis process of thermocurdlan

[0040] Thermogel is insoluble in water, but soluble in alkaline solution. Weigh 20g hot gel powder and dissolve in 1000mL1.0mol L -1 In the NaOH solution, stir magnetically for 3-4h until it is fully dissolved. Slowly add 5mol·L -1 The HCl solution is neutralized to neutral, and the neutralization solution is at 8000r·min -1 Centrifuge for 10 min, and wash the precipitate with water 2-3 times. Resuspend the pellet at 50°C, pH 6.0, 0.025mol L -1 In sodium phosphate buffer, 1000 mL of thermal gel ultrafine suspension was obtained. Add 200mL of 570U / mL β-1,3 glucan hydrolase crude enzyme solution (Journal of Food and Biotechnology, 2015, 34(11):1146-1154.), react at 50°C for 3h, after the reaction The temperature was raised to 80° C., and the reaction was terminated for 10 minutes to obtain a partial hydrolyzate of thermogelling polysaccharide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com