Method for degrading gossypol in cottonseed oil

A cottonseed oil and gossypol technology, which is applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of no cottonseed oil degossypol process, long processing time, etc., and achieve the effects of low cost, simple design and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

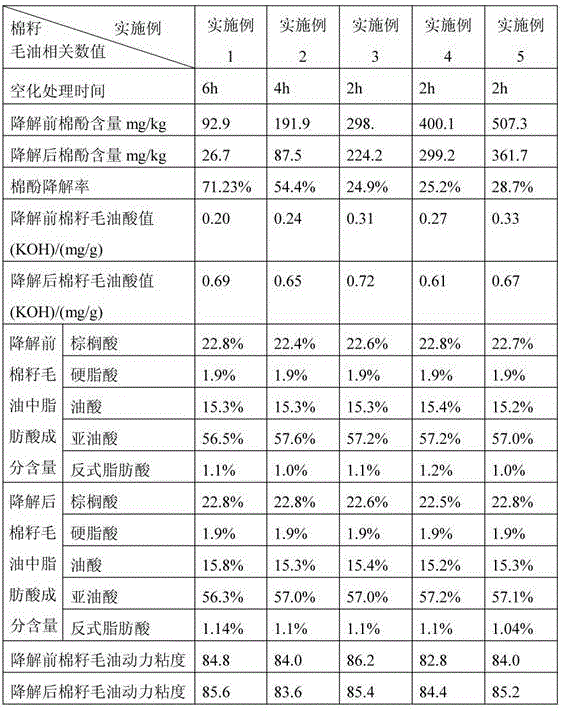

Embodiment 1- Embodiment 5

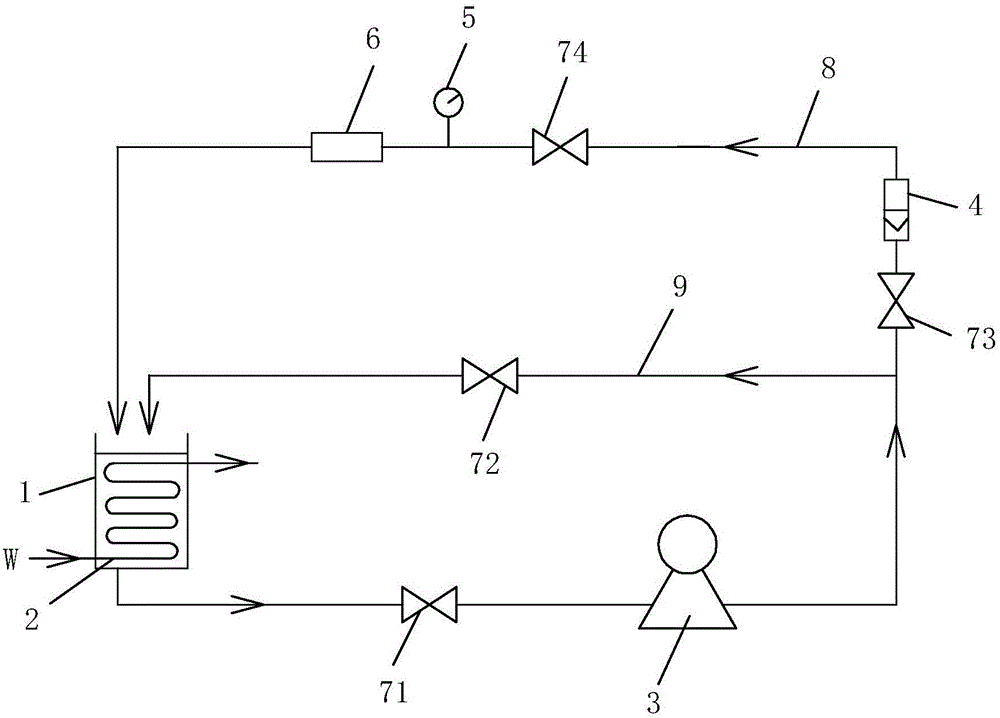

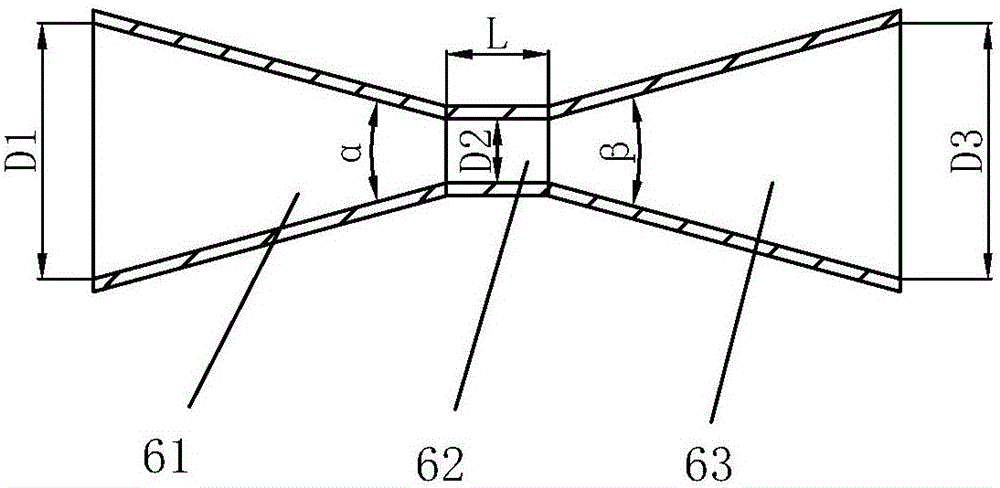

[0018] Embodiment 1-Example 5: A method for degrading gossypol in cottonseed oil, comprising the following steps: placing gossypol-containing cottonseed crude oil in a hydraulic cavitation device, and carrying out hydraulic cavitation treatment to cottonseed crude oil by circulation, The hydraulic cavitation device includes an adjustable bypass line 9 and a liquid storage tank 1, a pump 3, a flow meter 4, and a cavitator 6 that are connected in sequence through a pipeline 8, and the cavitator 6 is connected to the liquid storage tank 1 through a pipeline. Connected, the liquid storage tank 1 is provided with a condensate coil 2, one end of the adjustment bypass line 9 is connected with the liquid storage tank 1, and the other end is connected with the flow meter and the pipeline 8 between the pump, and the adjustment bypass line 9 and Control valves are arranged on the passage pipes 8 , and a pressure gauge 5 is installed on the pipe 8 at the inlet end of the cavitator 6 . Des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com