A kind of preparation method of cbz-valganciclovir

A technology of ganciclovir and ganciclovir condensate is applied in the field of preparation of CBZ-valganciclovir, and achieves the effects of high production efficiency, reduced production cost and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

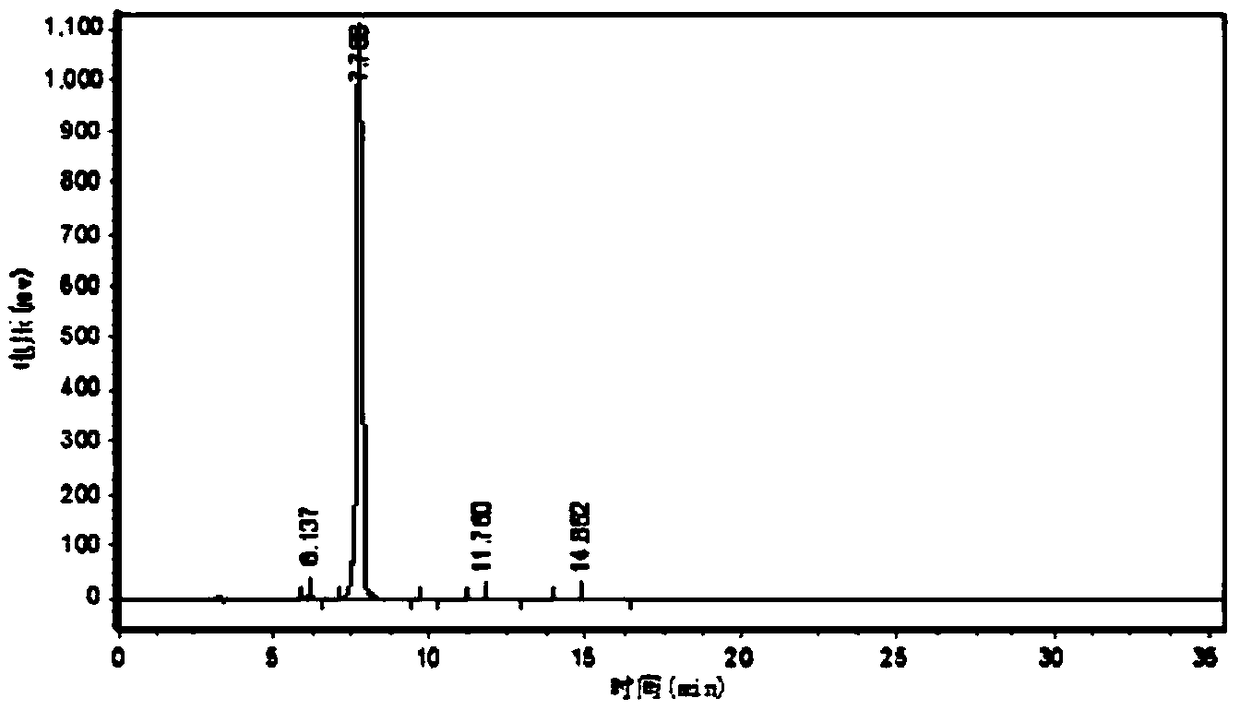

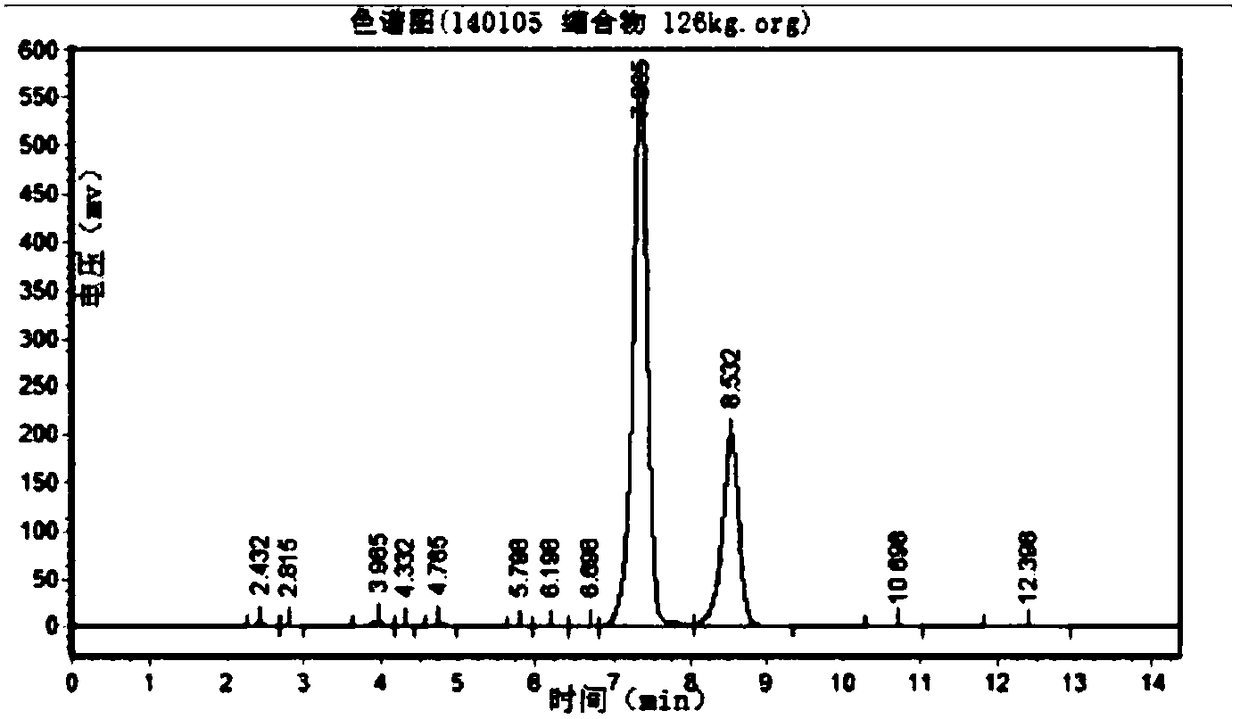

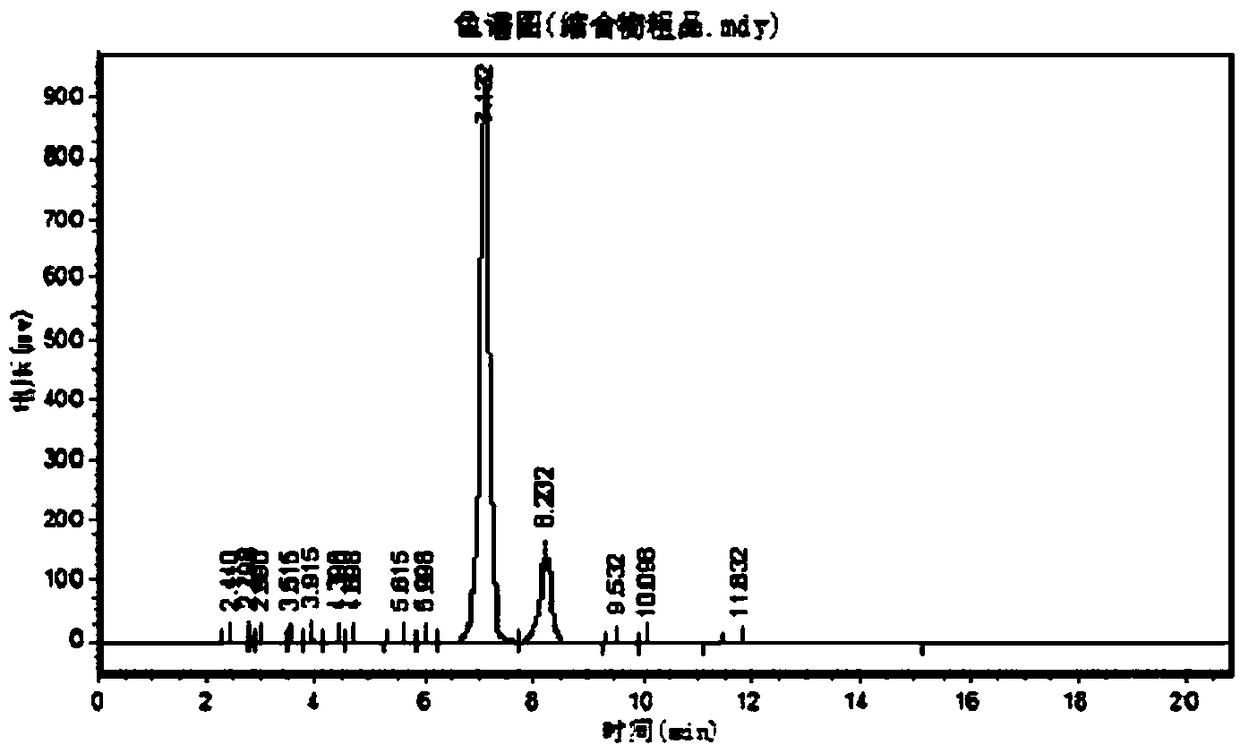

Image

Examples

Embodiment 1

[0080] A kind of CBZ-valganciclovir preparation method, it comprises the steps:

[0081] (1) 40kg ganciclovir condensate 7-position isomer, 3.0kg p-toluenesulfonic acid, 400kg solvent-DMF, 77kg1,3-diacetoxy-2-(acetoxymethoxy)propane, 60kg Put diacetylguanine into a 1000L reaction kettle, add 40kg of acetic anhydride, keep warm at 80-140°C for 3-5h and stir, then distill the acetic anhydride, continue to keep warm at 120-130°C for 18 hours, and distill 2- 3 times of acetic anhydride, so that the chemical balance reacts to the ganciclovir condensate;

[0082] (2) After the reaction in the step (1) ends, concentrate under reduced pressure and evaporate acetic anhydride and solvent-DMF until there is basically no evaporation to obtain a residue;

[0083] (3) Add 500L of ethyl acetate to the residue obtained in step (2), then heat up to reflux, cool down to 0-5°C, and keep warm for 1-24 hours for crystallization;

[0084](4) The product obtained in the step (3) is centrifuged and...

Embodiment 2

[0104] A kind of CBZ-valganciclovir preparation method, it comprises the steps:

[0105] (1) Put 100kg 7-position isomer of ganciclovir condensate, 3.0kg p-toluenesulfonic acid, 300kg solvent-DMF, 15kg1,3-diacetoxy-2-(acetoxymethoxy)propane into 1000L Add 100kg of acetic anhydride to the reaction kettle, keep it warm at 80-140°C for 3-5 hours and stir it, then distill the acetic anhydride, and continue to keep warm at 120-130°C for 18 hours, distilling the acetic anhydride 2-3 times during the period, so that Chemical equilibrium reaction to ganciclovir condensate;

[0106] (2) After the reaction in the step (1) ends, concentrate under reduced pressure and evaporate acetic anhydride and solvent-DMF until there is basically no evaporation to obtain a residue;

[0107] (3) Add 500L of ethyl acetate to the residue obtained in step (2), then heat up to reflux, cool down to 0-5°C, and keep warm for 1-24 hours for crystallization;

[0108] (4) The product obtained in the step (3) ...

Embodiment 3

[0118] A kind of CBZ-valganciclovir preparation method, it comprises the steps:

[0119] (1) 30kg ganciclovir condensate 7-isomer, 30kg ganciclovir 7-isomer, 2.3kg p-toluenesulfonic acid, 330kg solvent-DMF, 60kg1,3-diacetoxy-2- (Acetoxymethoxy) propane, 45kg diacetylguanine into a 1000L reactor, add 140kg acetic anhydride, keep warm at 80~140℃ for 3~5h and stir, then distill acetic anhydride, continue at 120-130 Keep warm for 18 hours under high temperature conditions, distill acetic anhydride 2-3 times during this period, so that the chemical equilibrium will react to the ganciclovir condensate;

[0120](2) After the reaction in the step (1) ends, concentrate under reduced pressure and evaporate acetic anhydride and solvent-DMF until there is basically no evaporation to obtain a residue;

[0121] (3) Add 500L of ethyl acetate to the residue obtained in step (2), then heat up to reflux, cool down to 0-5°C, and keep warm for 1-24 hours for crystallization;

[0122] (4) The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com