Preparation and application of conductivity-controllable fly ash-based geopolymer material

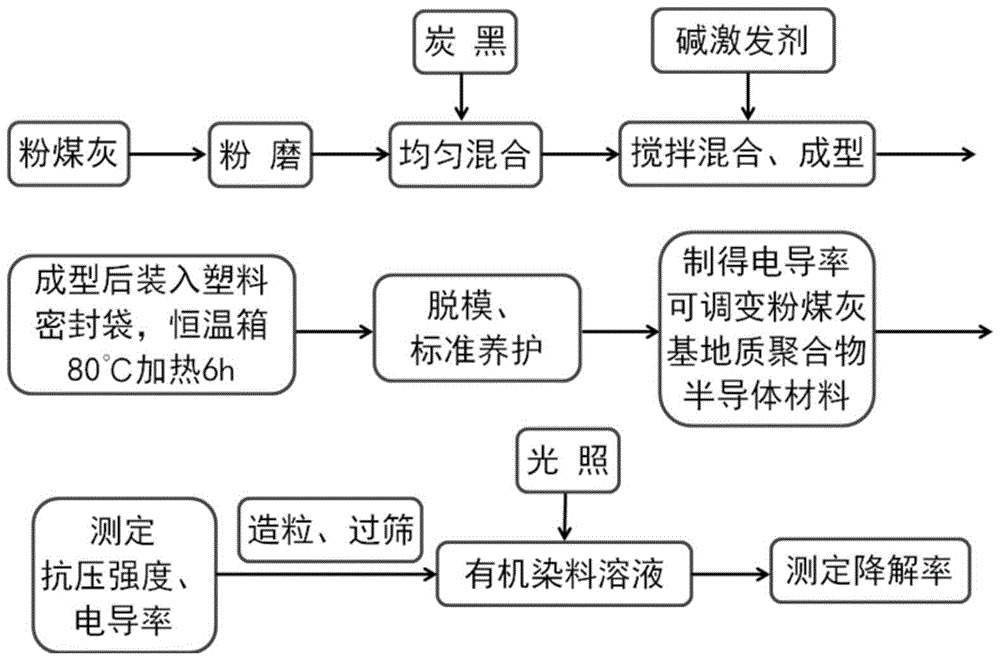

A technology of fly ash and conductivity, applied in the degradation of dyes, the conductivity can be adjusted in the field of preparation of fly ash-based geopolymer semiconductor materials, and can solve the problem of geopolymerization of fly ash that has not been found to modulate alkali with carbon black Preparation methods of semiconductor materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0080] Accurately take by weighing 300g of the fly ash raw material, take this as the measurement basis (100%), adopt the external mixing method, the solid potassium hydroxide dosage is 7% of the fly ash quality, and the sodium silicate nonahydrate dosage is the fly ash 15% of the mass, the mass of water is 30% of the mass of fly ash.

[0081] Weigh water according to the formula amount, dissolve solid sodium silicate nonahydrate and solid potassium hydroxide in water, pour the prepared potassium hydroxide solution and sodium silicate nonahydrate solution into a double-rotation double-speed slurry mixer, and then add Stir the fly ash to form a uniform slurry through chemical reaction; put the slurry into a triple mold of 3cm (width) × 4cm (height) × 5cm (length), vibrate it on the mortar vibrating table, and then Insert 4 pieces of galvanized stainless steel electrodes at equal distances [specification: 2cm (width) × 3cm (length)], seal them with a plastic film sealing bag, pl...

preparation Embodiment 2

[0083] Accurately weigh 300g of the fly ash raw material, take this as the measurement basis (100%), adopt the external mixing method, the content of carbon black is 0.5% of the mass of the fly ash, and the content of solid potassium hydroxide is the mass of the fly ash 7%, the content of solid sodium silicate nonahydrate is 15% of the mass of fly ash, and the mass of water is 32% of the mass of fly ash.

[0084] Weigh the water according to the formula, dissolve the solid sodium silicate nonahydrate and solid potassium hydroxide in water, and prepare the prepared potassium hydroxide solution and sodium silicate nonahydrate solution.

[0085] Pour the fly ash and carbon black into the mixer for full stirring and evenly mixing; pour the mixed alkali solution of potassium hydroxide and sodium silicate nonahydrate into the double-turn double-speed pure slurry mixer and thoroughly mix the fly ash and carbon black. Mixing, and the remaining steps are the same as in Example 1, to ob...

preparation Embodiment 3

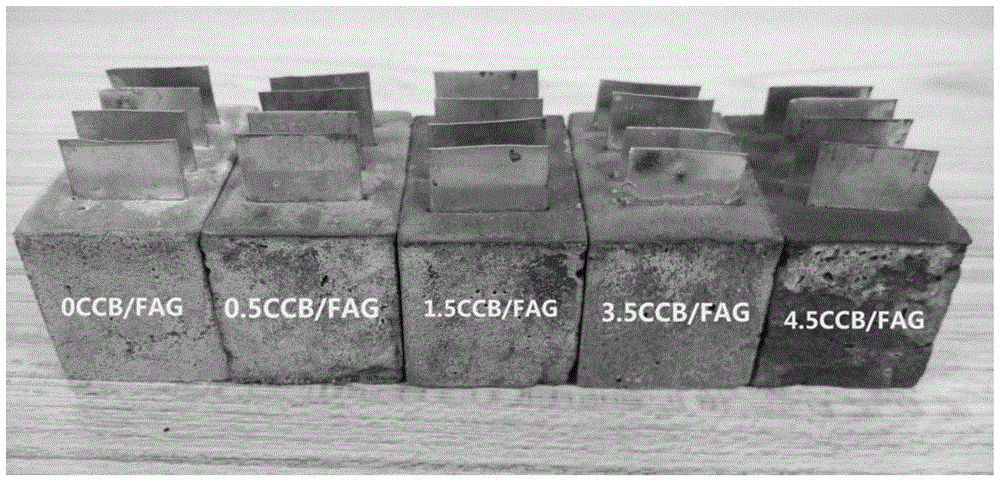

[0087] All the operation steps are the same as in Example 2, except that the amount of carbon black is 1.5% of the mass of the fly ash, and the quality of water is 35% of the mass of the fly ash. FlyAshGeopolymer, abbreviated as: FAG) semiconductor material test block (marked as: 1.5CCB / FAG), such as image 3 shown. The 3d compressive strength was measured to be 44.3MPa, and the conductivity of the prepared fly ash-based geopolymer semiconductor material test block at 3d, 7d, 14d and 28d at different ages was detected by the four-electrode method. The results are shown in the table. 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com