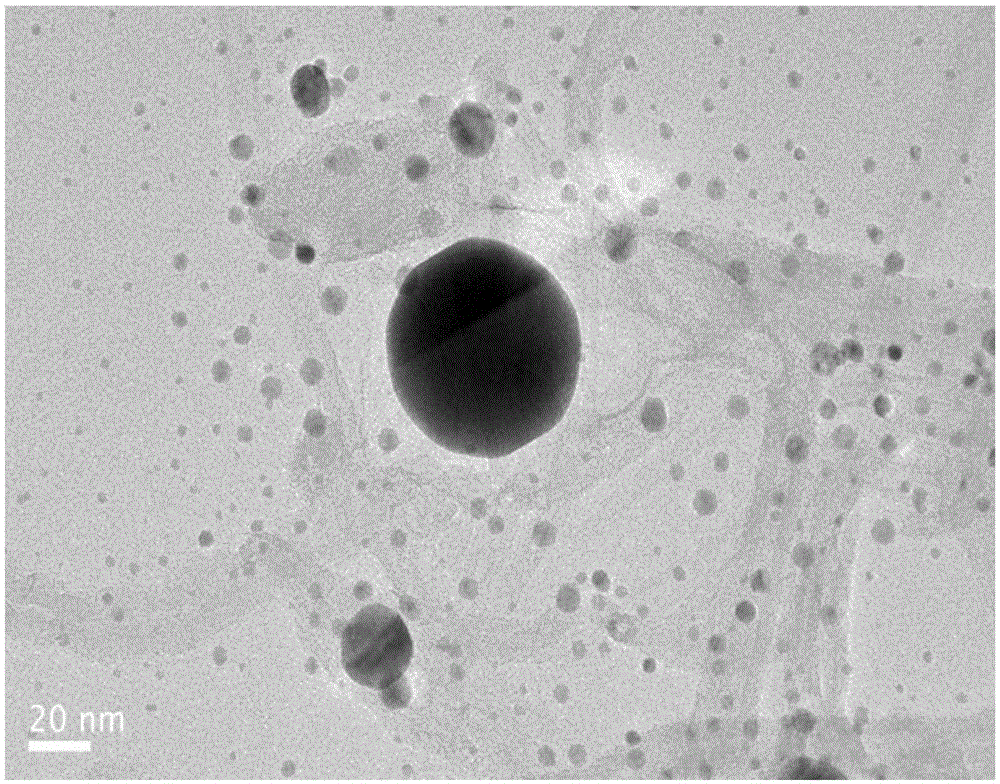

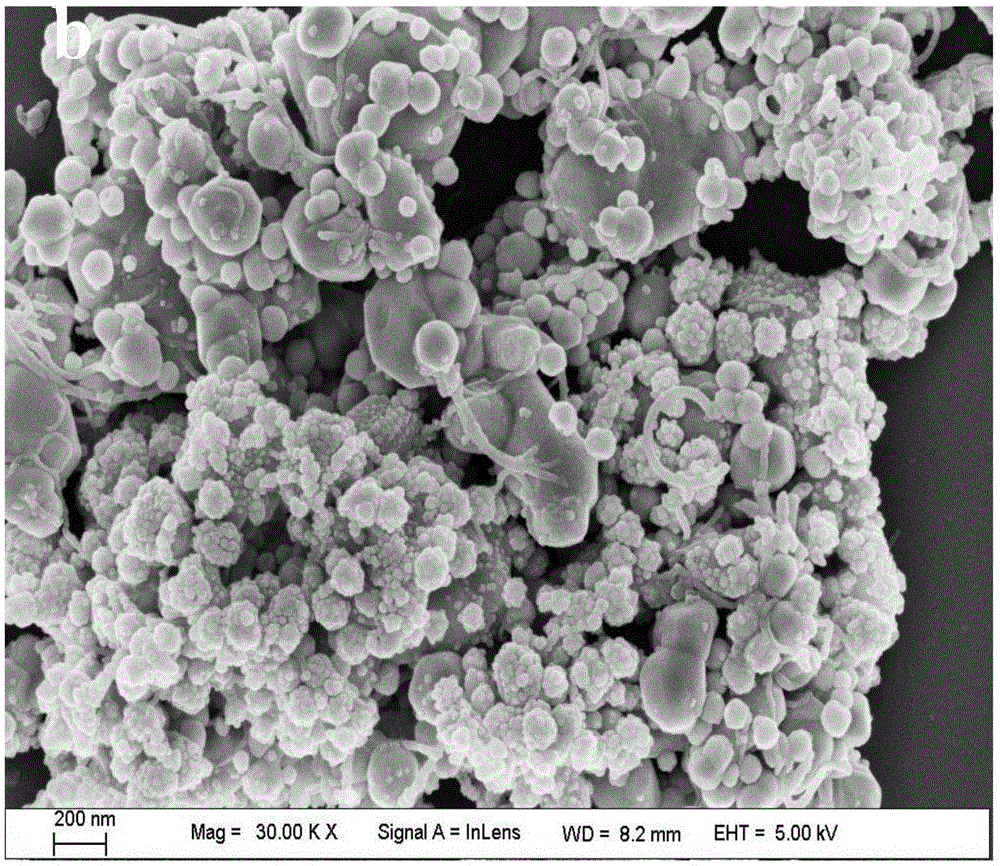

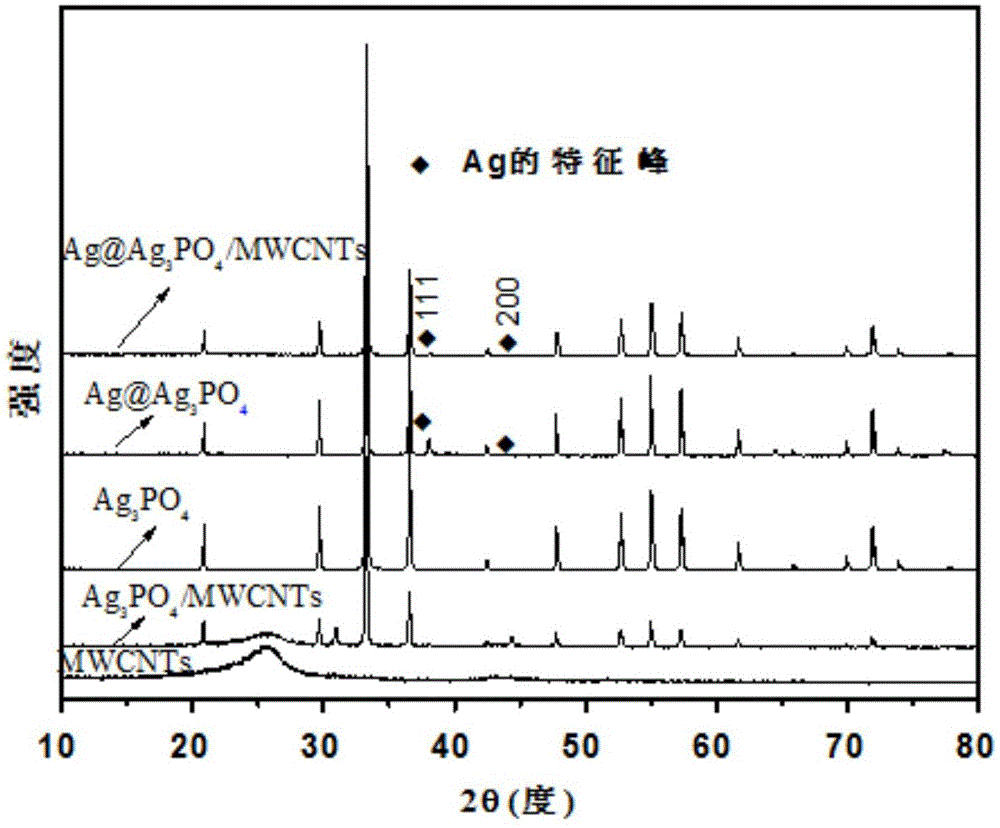

Preparation process of complex photocatalyst with multiwalled carbon nanotube loading silver/silver phosphate core-shell structure

A technology of multi-walled carbon nanotubes and core-shell structure, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of short production cycle, uniform particle size, and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 4.3 g of multi-walled carbon nanotubes, put them in a mortar and grind for 20 minutes, then add them to a 250 ml conical flask, inject 100 ml of 65% nitric acid, and ultrasonically disperse for 1 hour. Then put the ultrasonicated sample into a 250ml three-necked flask, place it on a heating mantle, stir magnetically at 115°C and reflux for 12h. After refluxing, it is cooled to room temperature and washed repeatedly with deionized water and absolute ethanol until it is neutral. The obtained black sample is dried in a drying oven at 100° C. to obtain purified multi-walled carbon nanotubes.

[0020] Weigh 0.33g of diammonium hydrogen phosphate, 0.33g of polyvinylpyrrolidone (PVP-K30) and 4.3g of purified multi-walled carbon nanotubes under magnetic stirring and add them to a three-necked flask containing 60ml of ethylene glycol to prepare Solution A. Weigh 0.85g silver nitrate and dissolve it in 15ml ethylene glycol to prepare solution B. Use a pipette to inject solut...

Embodiment 2

[0022] Weigh 6.5g of multi-walled carbon nanotubes, put them in a mortar and grind for 20 minutes, then add them to a 250ml conical flask, inject 150ml of 70% nitric acid, and ultrasonically disperse for 0.5h. Then put the ultrasonic sample into a 250ml three-necked flask, place it on a heating mantle, magnetically stir at 125°C and reflux for 6h. After refluxing, it was cooled to room temperature, and washed repeatedly with deionized water and absolute ethanol until it became neutral. The obtained black sample was dried in a drying oven at 50°C to obtain purified multi-walled carbon nanotubes.

[0023] Weigh out 0.13g of diammonium hydrogen phosphate, 0.13g of polyvinylpyrrolidone (PVP-K30) and 6.5g of purified multi-walled carbon nanotubes under magnetic stirring and add them to a three-necked flask containing 80ml of ethylene glycol to prepare Solution A. Weigh 0.34 g of silver nitrate and dissolve it in 10 ml of ethylene glycol to prepare solution B. Use a pipette to inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com