A method for preparing sediment covering material from water purification plant sludge as a resource

A covering material, a technology for water purification plants, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., and can solve problems such as high disposal costs, secondary pollution, reduction, etc. , to achieve the effect of moderate hydraulic conductivity, good adsorption effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

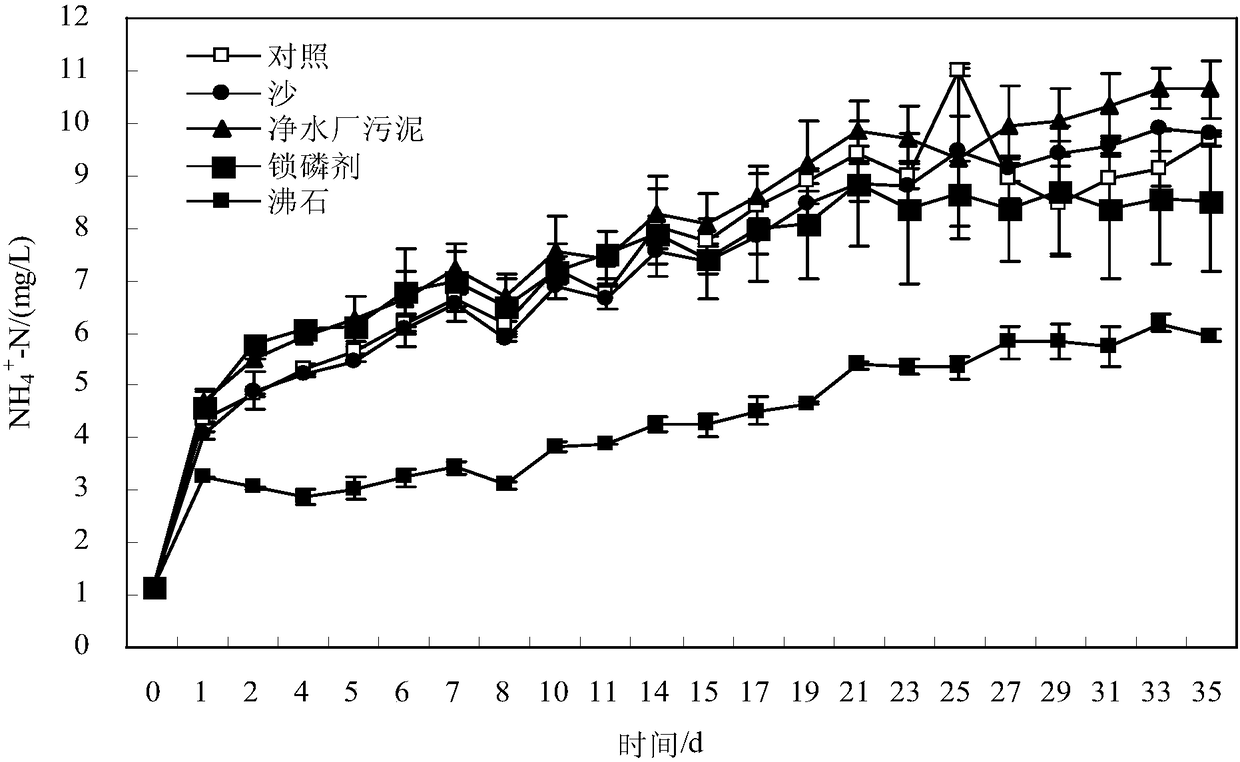

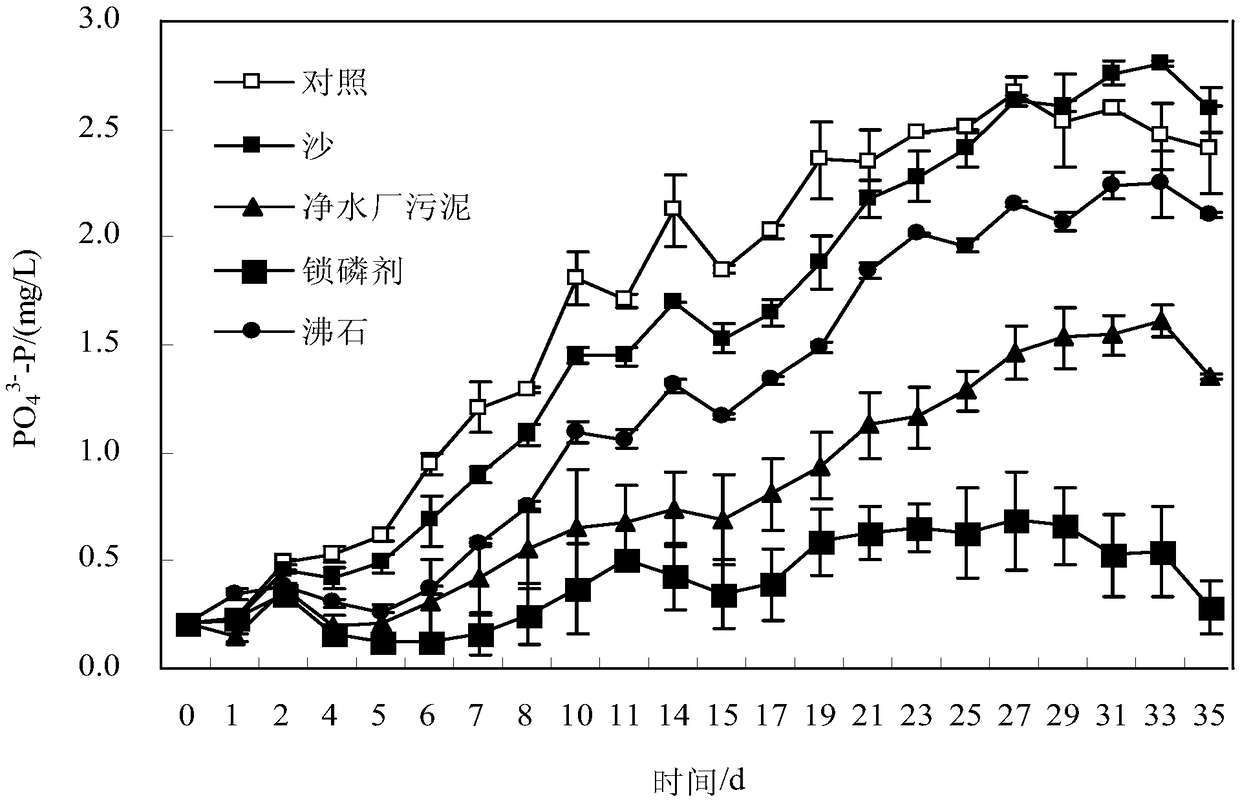

[0028] Example 1 Feasibility Study on Controlling the Release of Nitrogen and Phosphorus from Sediment by Sludge Covering in Water Purification Plant

[0029] (1) Test plan

[0030] The test was carried out in 10L, DN 200mm wide-mouth glass bottles; the weight of sediment in each bottle was about 1.39kg, and the thickness was about 5cm. The covering strength of the covering material is 2kg / m 2 (weight is 63g). The lake water is slowly added into the bottle along the bottle wall by using the siphon principle through the plastic hose, and the volume of the overlying water is about 8L.

[0031] There are 10 glass bottles in the test, which are divided into 5 groups, and each group has 2 parallel bottles, numbered 1-5#, among which, 1# is the control system, which is not covered with any materials; 2# is the sand covering system; 3# water purification plant Pollution coverage system; 4# phosphorus-locking agent coverage system; 5# zeolite coverage system.

[0032] The test sta...

Embodiment 2

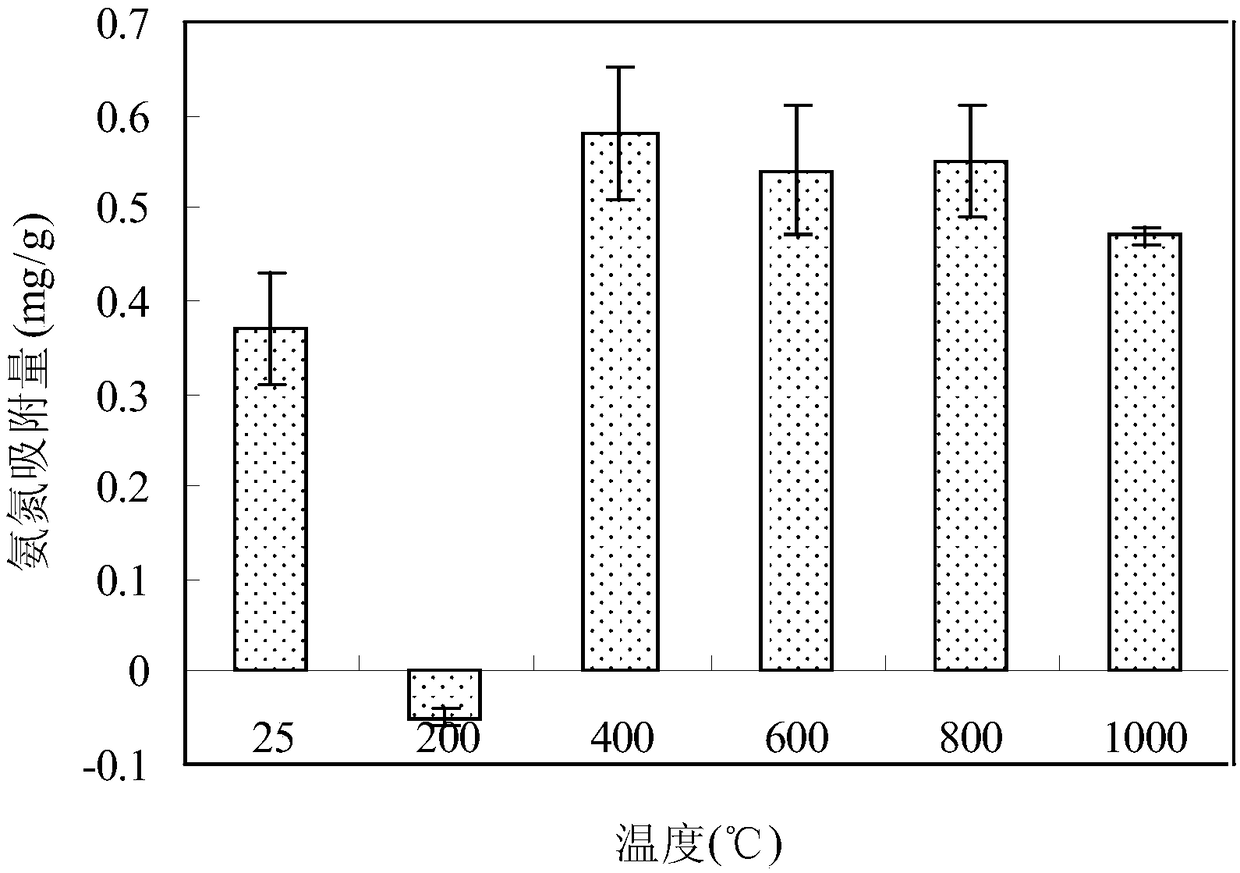

[0039] Example 2 Determination of optimal conditions for sludge calcination in water purification plants

[0040] (1) Test plan

[0041] Air-dry, mechanically pulverize and mechanically sieve the sludge cake from the water purification plant to obtain particles with a particle size of 1-3mm; 3h to prepare sludge granules; ②Calcinate at 400℃ for different time (1h, 2h, 3h, 4h, 5h, 6h) to prepare sludge granules; weigh 2.0g of sludge granules, put them into 200mL , NH with an initial concentration of 30mg / L 4 Cl solution or an Erlenmeyer flask with an initial concentration of 2mg / L orthophosphate, at 25°C and 150r / min, shake at a constant temperature in a water bath, take a sample after reacting for 24 hours, test the concentration of ammonia nitrogen and orthophosphate in the sample respectively, and then calculate The amount of adsorption of ammonia nitrogen and orthophosphate by sludge particles.

[0042] According to the amount of ammonia nitrogen and orthophosphate adsor...

Embodiment 3

[0048] Example 3 Study on Influencing Factors of Sludge Granules on the Adsorption Effect of Ammonia Nitrogen and Orthophosphate

[0049] (1) Test plan

[0050] The sludge from the water purification plant was calcined at 400°C for 4 hours, and the sludge particles with a particle size of 1-3mm were obtained through mechanical crushing and mechanical screening; , the adsorption capacity of sludge particles to ammonia nitrogen and orthophosphate; and orthophosphate adsorption capacity; ③Respectively investigate the initial concentration of ammonia nitrogen at 5mg / L, 10mg / L, 15mg / L, 20mg / L, 25mg / L, 30mg / L, or the initial concentration of orthophosphate at 0.5mg / L, Under the conditions of 1mg / L, 2mg / L, 4mg / L, and 8mg / L, the adsorption capacity of ammonia nitrogen and orthophosphate by sludge particles; the solution volume is 200mL, the water temperature is 25°C, the rotation speed is 150r / min, and the water bath is oscillating at a constant temperature; When the influence of pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com