A kind of porous ceramsite Fenton catalyst and preparation method thereof

A technology of porous ceramics and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve problems such as inconvenient use, and achieve cheap prices and raw materials Simple, mechanically strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

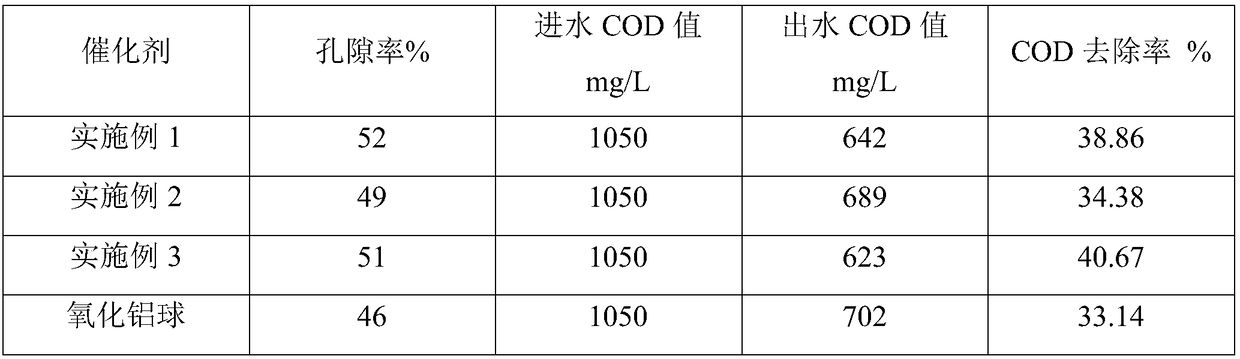

Embodiment 1

[0026] Take 2.4kg of sludge, 0.6kg of clay, 0.4kg of kaolin, 0.4kg of fly ash, 0.2kg of fumed silica, 0.1kg of copper oxide, and 0.1kg of iron oxide, and mix them well to form The ceramsite short columnar billet is heated in a high-temperature furnace at a temperature of 10°C to 500°C, pre-fired at a constant temperature for 20 minutes, then heated to 1100°C at a rate of 5°C / min, sintered for 20 minutes, and cooled to 300°C at a rate of 10°C / min Next, take it out and cool it naturally, the appearance of the porous ceramsite carrier is light brick red short columnar solid particles.

Embodiment 2

[0028]Take 2.0kg of sludge, 0.6kg of clay, 0.6kg of kaolin, 0.6kg of fly ash, 0.2kg of water glass, 0.15kg of copper chloride, and 0.2kg of ferrous sulfate and mix them well to form The ceramsite short columnar billet is heated in a high-temperature furnace at a temperature of 10°C to 500°C, pre-fired at a constant temperature for 20 minutes, then heated to 1100°C at a rate of 5°C / min, sintered for 20 minutes, and cooled to 300°C at a rate of 10°C / min Next, take it out and cool it naturally, the appearance of the porous ceramsite carrier is light brick red short columnar solid particles.

Embodiment 3

[0030] Take 2.4kg of sludge, 0.6kg of clay, 0.6kg of kaolin, 0.6kg of fly ash, 0.2kg of fumed silica, 0.1kg of copper sulfide, and 0.2kg of ferrous sulfate and mix them well to form The ceramsite short blank is heated in a high-temperature furnace at a temperature of 10°C to 500°C, pre-fired at a constant temperature for 20 minutes, then heated to 1150°C at a rate of 5°C / min, sintered for 15 minutes, and cooled to below 300°C at a rate of 10°C / min , Take out and cool naturally, the appearance of the porous ceramsite carrier is light brick red short columnar solid particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com