M-contained multifunctional metal oxide modified high-voltage lithium cobalt oxide positive electrode powder material and preparation method therefor

A powder material, lithium cobalt oxide technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable cycle performance, improvement, etc., to achieve the effect of improving discharge specific capacity, increasing volume energy density, and improving crystallization integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

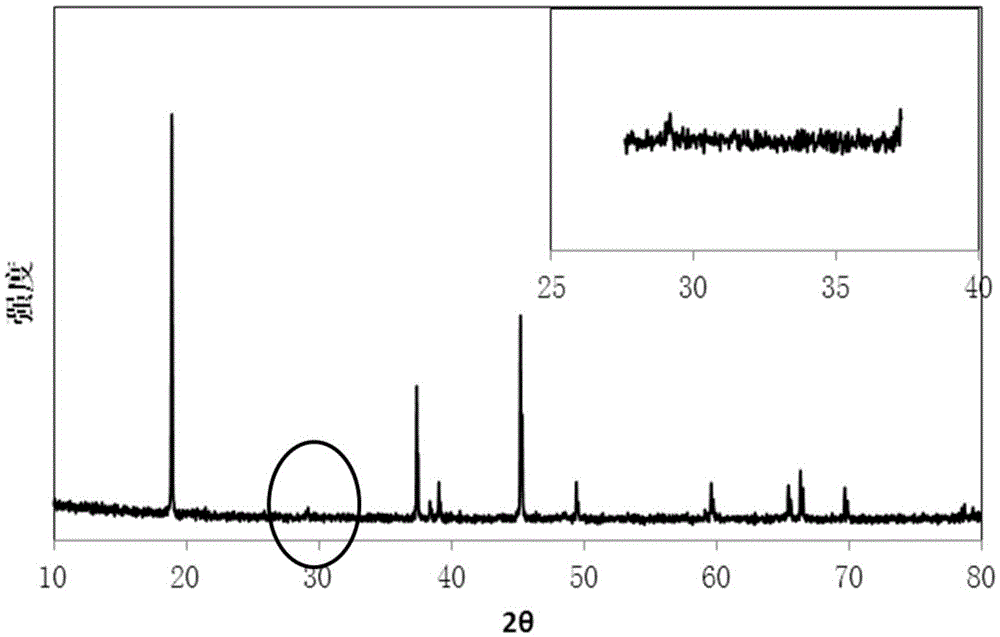

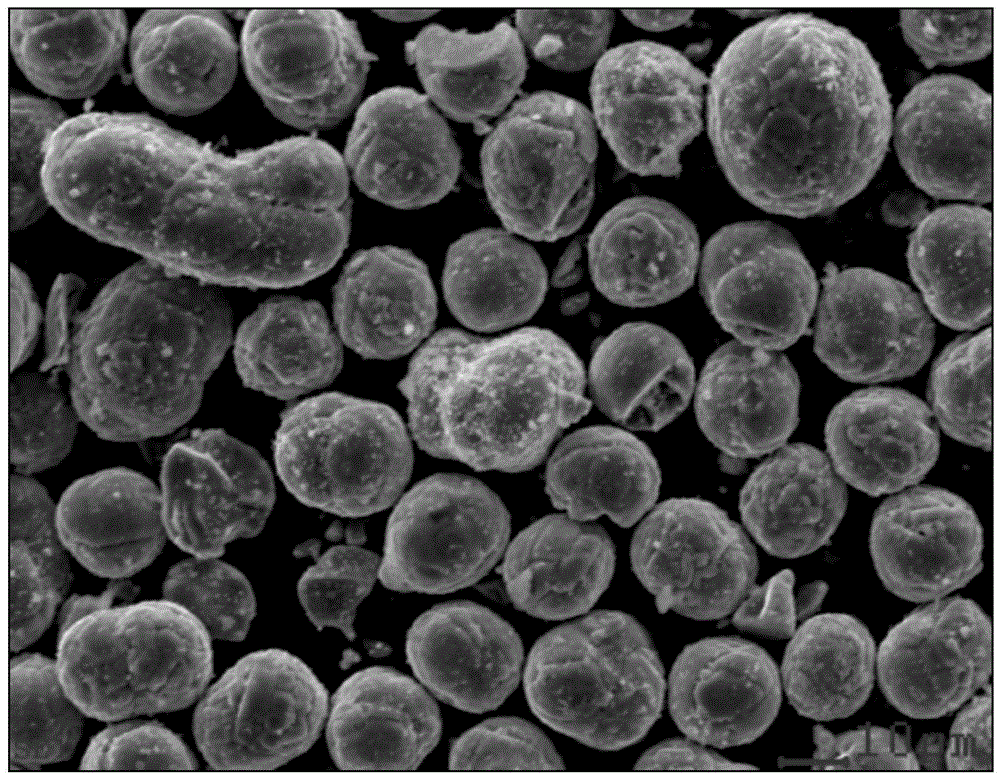

[0041] A high-voltage lithium cobaltate positive electrode powder material modified by a multifunctional metal oxide containing M, the general formula of the positive electrode powder material is: Li 1.01 co 0.985 Al 0.005 Y 0.01 o 2 . The positive electrode powder material has a core-shell structure, and a layer of yttrium-containing aluminum composite oxide (Y 3 Al 5 o 15 ) inert protective layer.

[0042] The preparation method of the above-mentioned high-voltage lithium cobaltate positive electrode powder material in this embodiment includes the following steps:

[0043] With battery-grade cobalt oxide and battery-grade lithium carbonate as raw materials, yttrium oxide (Y 2 o 3 ) as a catalyst, aluminum oxide as an additive, the elemental molar ratio of Li:(Co+Al+Y) is controlled to be 1.01, and the elemental molar ratio of Al:Y:Co is controlled to be 0.005:0.01:0.985, and then placed in a ball mill and mixed uniform; put the above-mentioned homogeneously mixed m...

Embodiment 2

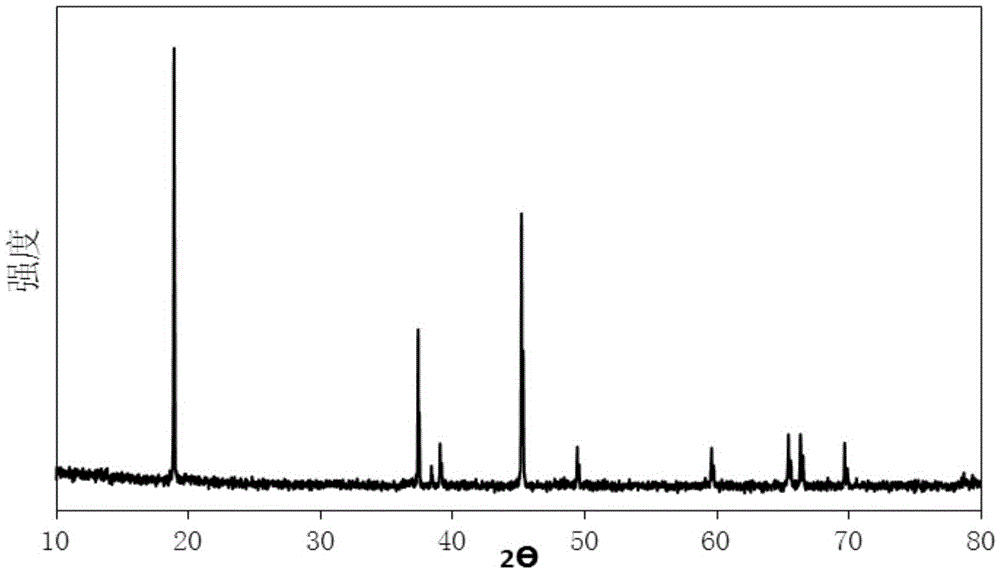

[0048] A high-voltage lithium cobaltate positive electrode powder material modified by the multifunctional metal oxide M of the present invention, the general formula of the positive electrode powder material is: Li 1.05 co 0.99 Al 0.005 Ti 0.005 o 2 . The positive electrode powder material has a core-shell structure, and a layer of titanium oxide (TiO 2 ) inert protective layer.

[0049] The preparation method of the above-mentioned high-voltage lithium cobaltate positive electrode powder material in this embodiment includes the following steps:

[0050] Using battery-grade cobalt oxide and battery-grade lithium carbonate as raw materials, titanium oxide (TiO 2 ) as a catalyst, aluminum oxide is an additive, the elemental molar ratio of controlling Li: Co is about 1.05, and the elemental molar ratio of Al: Ti: Co is controlled to be 0.005: 0.005: 0.990, and then placed in a ball mill and mixed uniformly; The uniform material is put into a bell furnace for sintering tre...

Embodiment 3

[0053] A high-voltage lithium cobaltate positive electrode powder material modified by the multifunctional metal oxide M of the present invention, the general formula of the positive electrode powder material is: Li 1.0 co 0.985 Mg 0.01 Sb 0.005 o 2 . The positive electrode powder material has a core-shell structure, and a layer of antimony oxide (Sb 2 o 3 ) inert protective layer.

[0054] The preparation method of the above-mentioned high-voltage lithium cobaltate positive electrode powder material in this embodiment includes the following steps:

[0055] Using battery-grade cobalt hydroxide (cobalt hydroxy), battery-grade lithium carbonate, and magnesium oxide as raw materials, antimony oxide (Sb 2 o 3 ) as a catalyst, control the molar ratio of Li: (Co+Sb+Mg) to 1.0, and the molar ratio of Mg: Sb: Co to be 0.01: 0.005: 0.985, then place it in a ball mill and mix uniformly; mix the above The uniform material is put into a bell furnace for sintering treatment. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com