Numerical-control water hydraulic variable piston pump

A variable plunger, digital control technology, applied in the field of positive displacement pumps, can solve the problems of high transmission and control requirements, low water cylinder movement speed, application limitations of variable pump systems, etc., to solve the working medium pollution, improve life and reliability. , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

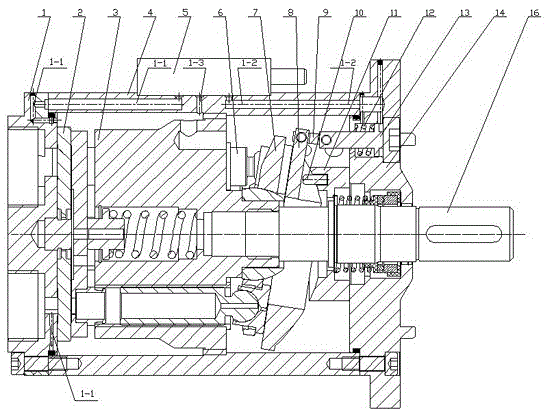

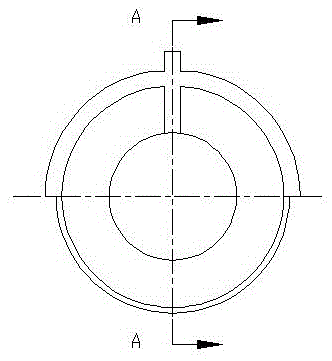

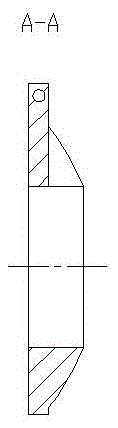

[0021] as attached figure 1 , 2 , 3, and 4, the present invention includes a rear end cover 1, a distribution plate 2, a rotating cylinder assembly 3, a housing 4, a water-hydraulic electro-hydraulic proportional valve 5, an odd number of plunger shoe assemblies 6, a return plate 7, Variable swash plate 8, connecting rod 9, swash plate bushing 11, variable spring 12, variable piston 13, front end cover 14 and shaft 16, A high-pressure water channel 1-1 and B high-pressure water channel 1 are respectively arranged on the housing 4 -2 and C high-pressure water channels 1-3, the rear end cover 1 and the front end cover 14 are respectively fixedly installed on both ends of the housing 4, the distribution plate 2 is installed on the rear end cover 1 and is located in the housing 4, and the return plate One side of 7 is installed on the front end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com