Sulfate trivalent chromium electroplating solution and preparation method thereof

A technology of trivalent chromium and electroplating solution, applied in the field of electroplating, which can solve the problems of slow plating deposition rate, white appearance of the plating layer, and failure to meet the requirements, etc., and achieve the effects of superior throwing ability, fast deposition rate of the plating layer, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

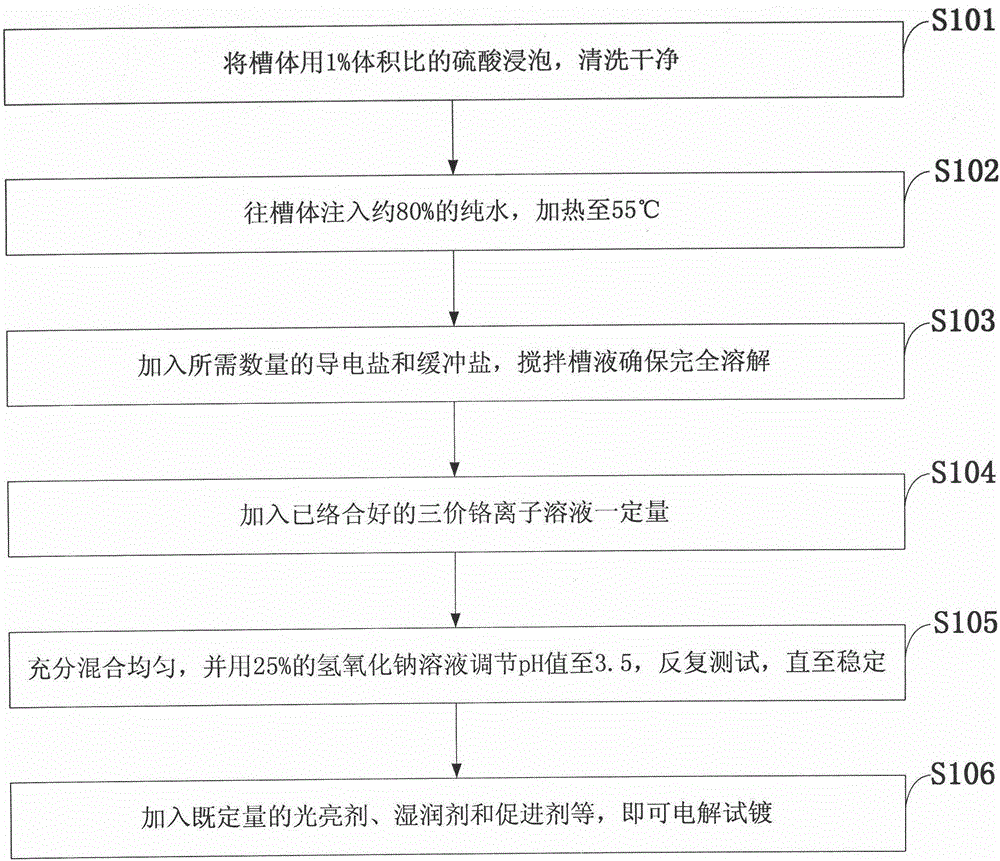

[0046] Such as figure 1 Shown, the preparation method of the sulfate trivalent chromium electroplating solution of the embodiment of the present invention may further comprise the steps:

[0047] S101: Soak the tank body with 1% by volume sulfuric acid and clean it;

[0048] S102: inject about 80% pure water into the tank, and heat to 55°C;

[0049] S103: Add the required amount of conductive salt and buffer salt, and stir the bath to ensure complete dissolution;

[0050] S104: adding a certain amount of complexed trivalent chromium ion solution;

[0051] S105: Mix well and adjust the pH value to 3.5 with 25% sodium hydroxide solution, and test repeatedly until it is stable;

[0052] S106: Add a predetermined amount of brightener, wetting agent and accelerator, etc., and electrolytic test plating can be performed.

[0053] The working principle of the present invention will be described in detail below.

[0054] In the present invention, the conductive component and the b...

Embodiment 1

[0057] Sodium sulfate 200g / L Boric acid 90g / L, basic chromium sulfate 60g / L, malic acid 15g / L, formic acid 1g / L, thiourea 0.005g / L, sodium saccharin reaction product 3g / L, sodium allyl sulfonate 0.5g / L, 0.5g / L sodium dihexyl succinate sulfonate, and the rest is water.

Embodiment 2

[0059] Potassium sulfate 210g / L, boric acid 100g / L, basic chromium sulfate 60g / L, malic acid 15g / L, formic acid 1g / L, thiourea 0.005g / L, sodium saccharin 3g / L, sodium allylsulfonate 0.5 g / L, sodium dihexyl sulfonate 0.5g / L, and the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com