Austenite stainless steel erosion agent and preparation method and application thereof

A technology of austenitic stainless steel and etchant, applied in the field of austenitic stainless steel etchant and its preparation, can solve the problems of high preservation and protection requirements, pitting corrosion, explosion, etc., so that the erosion process can be easily controlled and adverse effects can be avoided , the effect of high convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

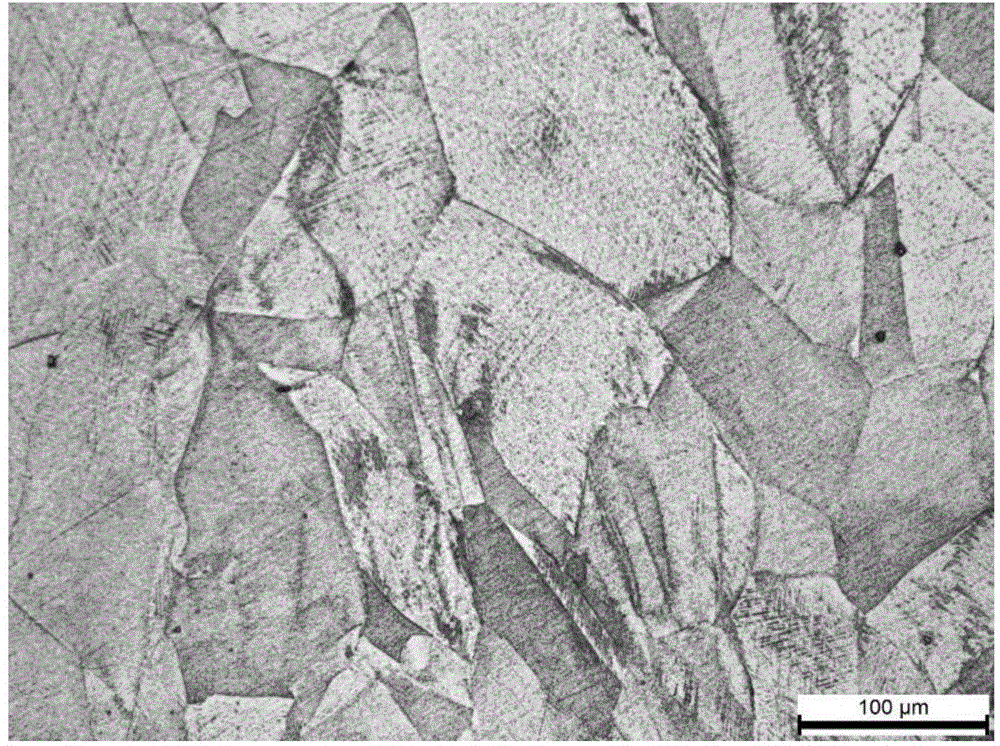

Image

Examples

Embodiment 1

[0036] The composition and ratio of etching agent are: 5ml concentrated nitric acid, 15ml concentrated hydrochloric acid, 5g ferric chloride, 50ml ethanol.

[0037] Its preparation is: add 50ml of ethanol to a reagent bottle or graduated cylinder; then add 5g of ferric chloride, shake slowly, and after it is fully dissolved, slowly add 15ml of concentrated hydrochloric acid and 5ml of concentrated nitric acid in turn, and let it stand for more than 3 hours.

[0038] After the preparation of the above-mentioned etchant components is completed, hold the absorbent cotton with tweezers, dip it in the etchant and wipe it on the surface of the sample for about 30 seconds, or if the surface of the sample turns gray.

[0039] After wiping, rinse with distilled water or ethanol, then wipe with a clean ethanol cotton ball, and dry the ethanol with an air blower or hair dryer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com