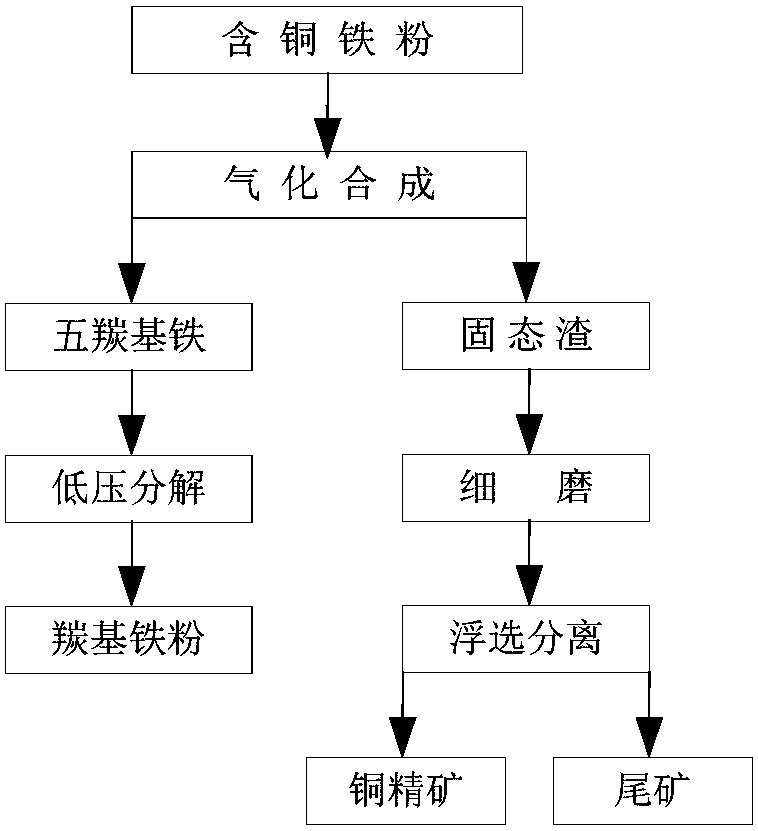

Method and system for processing copper-containing iron powder

A copper-iron and iron-pentacarbonyl technology, applied in the metallurgical industry, can solve problems such as many process steps, difficult large-scale industrial application, and harsh conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

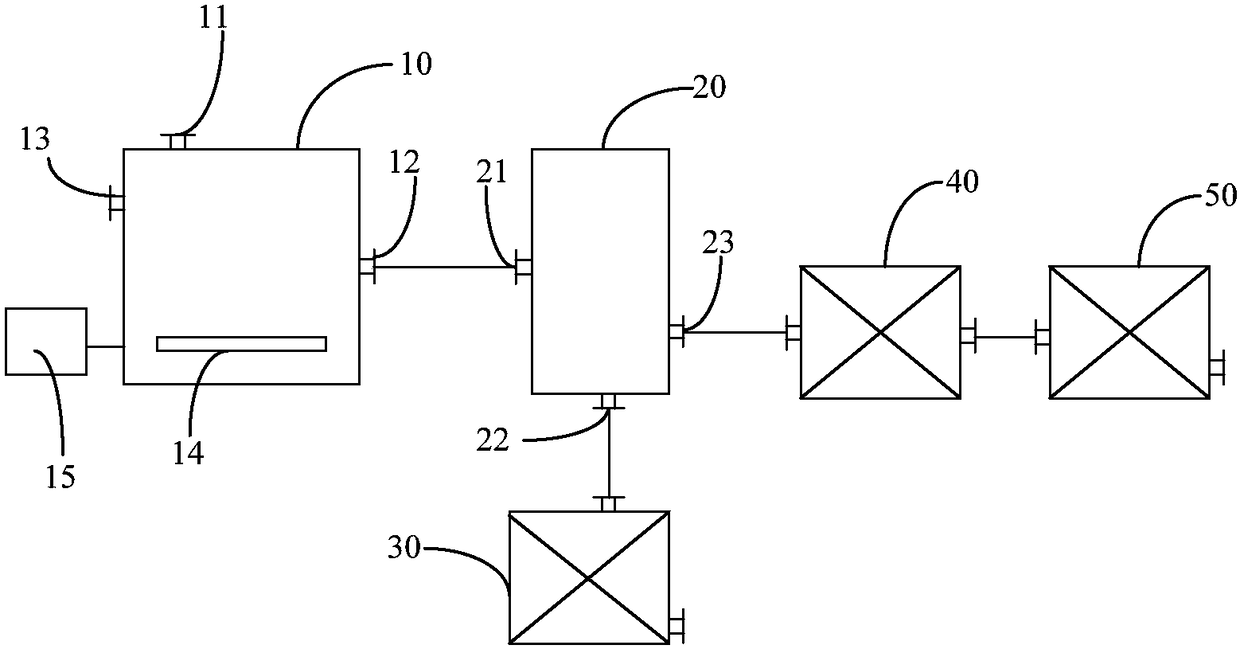

Method used

Image

Examples

Embodiment 1

[0047] [1] The copper-containing iron powder obtained after "copper slag-pelletizing-drying-rotary hearth furnace direct reduction-grinding magnetic separation" is processed, and its TFe grade is 88%, Cu content is 1%, S The content is 0.4%, and its particle size is -0.074mm, accounting for 60%.

[0048] [2] Put the copper-containing iron powder into the reactor, and then introduce the pressurized CO into the reactor, so that the pressure in the reactor is 15MPa, and heat the reactor at the same time, so that the temperature in the reactor reaches 180 ℃, so that the copper-containing iron powder undergoes a synthesis reaction to generate gaseous iron pentacarbonyl. At the same time, the sulfur in the iron powder gradually generates carbonyl sulfide, which reacts with part of the copper to generate Cu 2 S, to further promote the separation of copper and iron, the specific reaction equation is:

[0049] Fe+5CO=Fe(CO) 5

[0050] At the same time, the sulfur in the iron powder ...

Embodiment 2

[0058] [1] The copper-containing iron powder obtained after "nickel slag-pelletizing-drying-rotary hearth furnace direct reduction-grinding magnetic separation" is processed, and its TFe grade is 92%, Cu content is 0.5%, S The content is 0.3%, and its particle size is -0.074mm, accounting for 80%.

[0059] [2] Feed the copper-containing iron powder into the reactor, and then introduce the pressurized CO into the reactor, so that the pressure in the reactor is 12MPa, and heat the reactor at the same time, so that the temperature in the reactor reaches 200 ℃, so that the copper-containing iron powder undergoes a synthesis reaction to generate gaseous iron pentacarbonyl. At the same time, the sulfur in the iron powder gradually generates carbonyl sulfide, which reacts with part of the copper to generate Cu 2 S, to further promote the separation of copper and iron, the specific reaction equation is:

[0060] Fe+5CO=Fe(CO) 5

[0061] At the same time, the sulfur in the iron powd...

Embodiment 3

[0069] [1] The copper-containing iron powder obtained after "copper slag-raw material treatment-rotary kiln direct reduction-grinding magnetic separation" is processed, and its TFe grade is 94%, Cu content is 0.2%, and S content is 0.1%. , and its particle size is -0.074mm, accounting for 90%.

[0070] [2] Feed the copper-containing iron powder into the reactor, and then introduce the pressurized CO into the reactor, so that the pressure in the reactor is 10MPa, and heat the reactor at the same time, so that the temperature in the reactor reaches 220 ℃, so that the copper-containing iron powder undergoes a synthesis reaction to generate gaseous iron pentacarbonyl. At the same time, the sulfur in the iron powder gradually generates carbonyl sulfide, which reacts with part of the copper to generate Cu 2 S, to further promote the separation of copper and iron, the specific reaction equation is:

[0071] Fe+5CO=Fe(CO) 5

[0072] At the same time, the sulfur in the iron powder w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com