Method for recovering valuable metals from waste lithium-ion power batteries

A power battery and valuable metal technology, applied in battery recycling, waste collector recycling, recycling technology, etc., to achieve the effects of reliable process, convenient adjustment of processing capacity, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

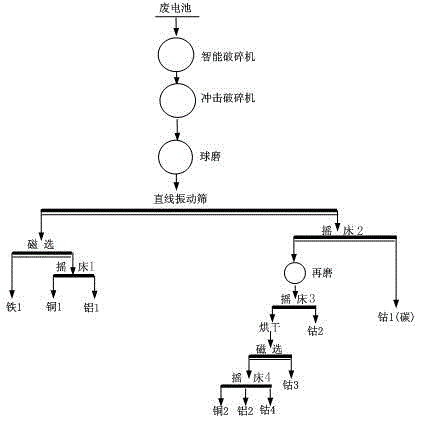

[0015] The present invention will be described in further detail below according to the accompanying drawings.

[0016] A method for recovering valuable metals from waste lithium-ion power batteries, which is carried out in the following steps:

[0017] (1) Take 5 kg of waste lithium-ion power battery after roasting, pour it into a low-intelligence crusher, add water at a concentration of 50% of the pulp, and flow into the impact crusher after crushing, add water at a concentration of 30% of the pulp, and then After crushing, it flows into the ball mill for grinding, and the grinding time is 10 minutes. Grinding discharge products flow to the single-layer vibrating screen for vibrating screening. Water can be added during sieving to speed up the sieving speed.

[0018] (2) The products on the sieve flow to the belt conveyor by itself, and the belt magnetic separator is installed at the front end of the conveyor to obtain metal Fe, and the non-magnetic products enter the shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com