Preparation method of doped carbon nitride fluorescent quantum dots

A technology of fluorescent quantum dots and carbon nitride, which is applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., can solve the limitation of mass production and wide application of carbon nitride quantum dots, and the size uniformity of quantum dots is not very ideal , low yield of quantum dots and other issues, to achieve the effect of small particle size, increased fluorescence luminescence intensity and fluorescence quantum yield, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

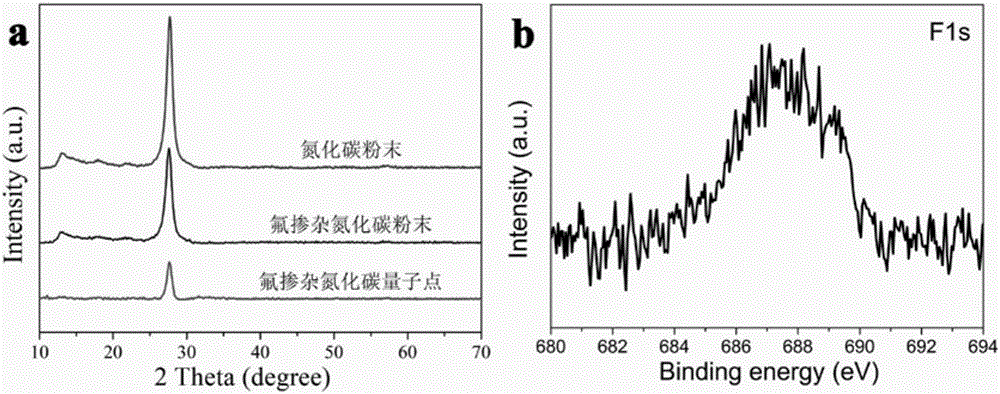

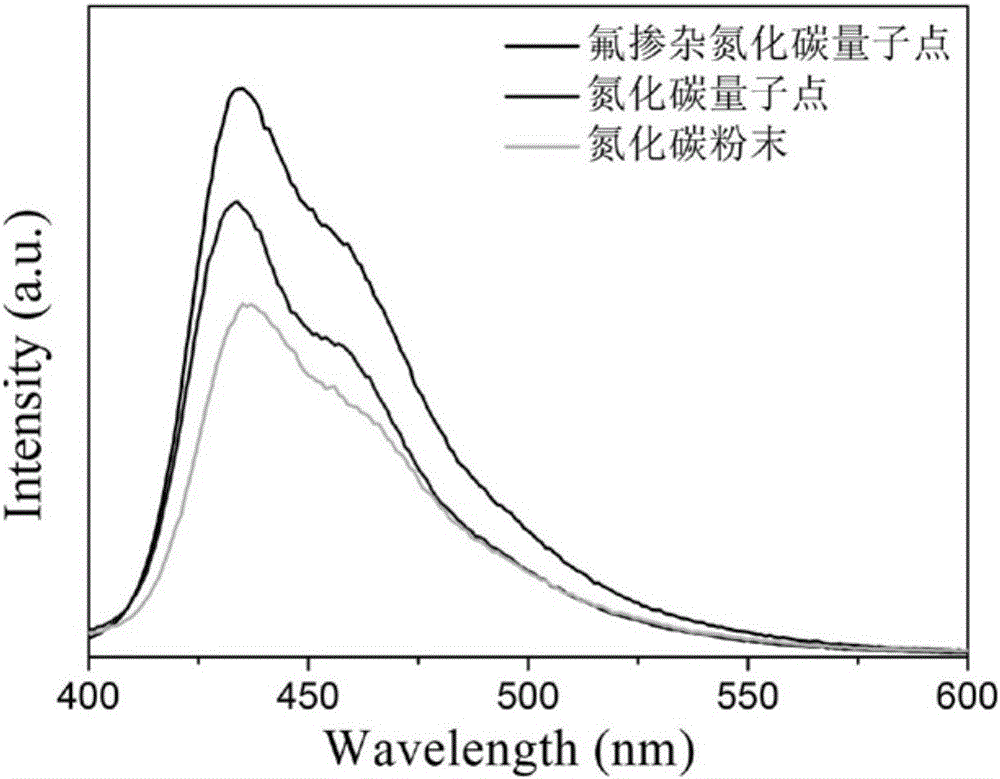

[0025] Weigh 1.0 g of melamine and 0.2 g of ammonium fluoride in a mass ratio of 5:1, add the melamine and ammonium fluoride to a mortar and grind and mix them. Put it into a crucible, calcine in a tube furnace at 550°C and keep it for 2 hours to obtain fluorine-doped carbon nitride powder material.

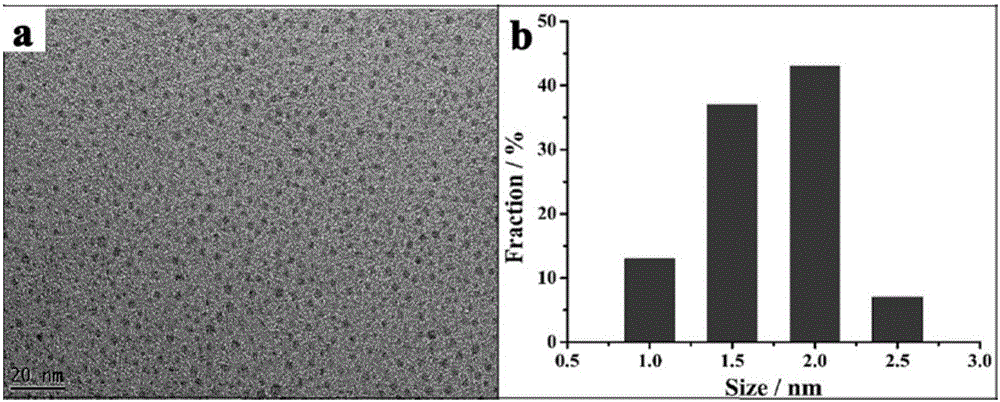

[0026] Put the prepared doped carbon nitride powder material into a centrifuge tube, add analytically pure ethylene glycol solution as a solvent, and add 1 g of doped carbon nitride powder per liter of ethylene glycol solution. The centrifuge tube was placed in an ultrasonic cleaning machine and ultrasonically broken for 5 hours at a power of 160 W, and the supernatant was taken and placed in a high-speed centrifuge at a centrifugal speed of 12000 rpm for 10 minutes to obtain a solution of highly fluorescent doped carbon nitride quantum dots. The above solution is placed in an oven at 60° C. and dried to constant weight to obtain fluorine-doped carbon nitride quantum dots. Such as ...

Embodiment 2

[0028] Weigh 1.0g of melamine and B at a mass ratio of 20:1 2 O 3 0.05g, combine melamine and B 2 O 3 Add to mortar and grind and mix well. Put it into a crucible, calcine in a tube furnace at 500° C. and keep it for 4 hours to obtain boron-doped carbon nitride powder material.

[0029] Put the prepared doped carbon nitride powder material into a centrifuge tube, and add analytical pure glycol solution as a solvent. Add 10g of doped carbon nitride powder per liter of ethylene glycol solution. The centrifuge tube was placed in an ultrasonic cleaning machine and ultrasonically broken at 170 W for 2 hours, and the supernatant was placed in a high-speed centrifuge at a centrifugal speed of 12000 rpm for 10 minutes to obtain a solution of highly fluorescent doped carbon nitride quantum dots. The above solution is placed in an oven at 60° C. and dried to a constant weight to obtain boron-doped carbon nitride quantum dots. The particle size is 3-4nm. The fluorescence quantum yield is...

Embodiment 3

[0031] Weigh 1.0 g of melamine and 0.2 g of thiourea according to a mass ratio of 5:1, add the melamine and thiourea into a mortar, grind and mix. Put it into a crucible, calcine in a tube furnace at 550°C and keep it for 4 hours to obtain sulfur-doped carbon nitride powder material.

[0032] Put the prepared sulfur-doped carbon nitride powder material into a centrifuge tube, and add analytically pure glycerol solution as a solvent. Add 5g of doped carbon nitride powder per liter of pure glycerol solution. The centrifuge tube was placed in an ultrasonic cleaner and ultrasonically broken for 5 hours at a power of 160W. Take the supernatant and place it in a high-speed centrifuge at a centrifugal speed of 12000 rpm for 10 minutes to obtain a solution of highly fluorescent doped carbon nitride quantum dots. The above solution is placed in an oven at 80° C. and dried to a constant weight to obtain sulfur-doped carbon nitride quantum dots. The particle size is 2-3nm. The fluoresce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com