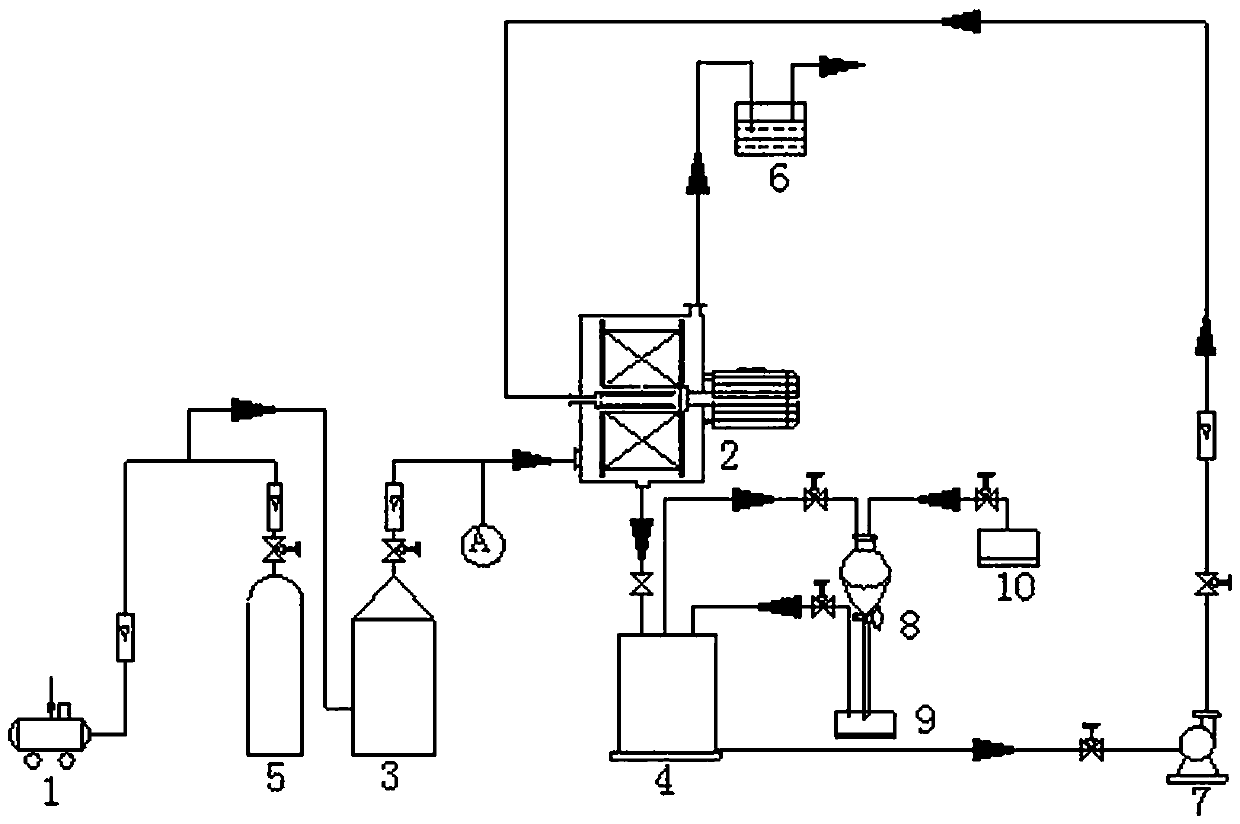

A device and process for treating ammonium chloride wastewater by high-gravity carbonization reaction

A technology of carbonization reaction and ammonium chloride, which is applied in the direction of ammonium chloride, ammonium halide, water/sewage treatment, etc., can solve the problems of high cost, difficult high-concentration ammonium chloride wastewater treatment, and ammonium chloride wastewater cannot be reached. , to achieve the effect of reducing operating costs, reducing carbonization reaction time, and shortening carbonization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

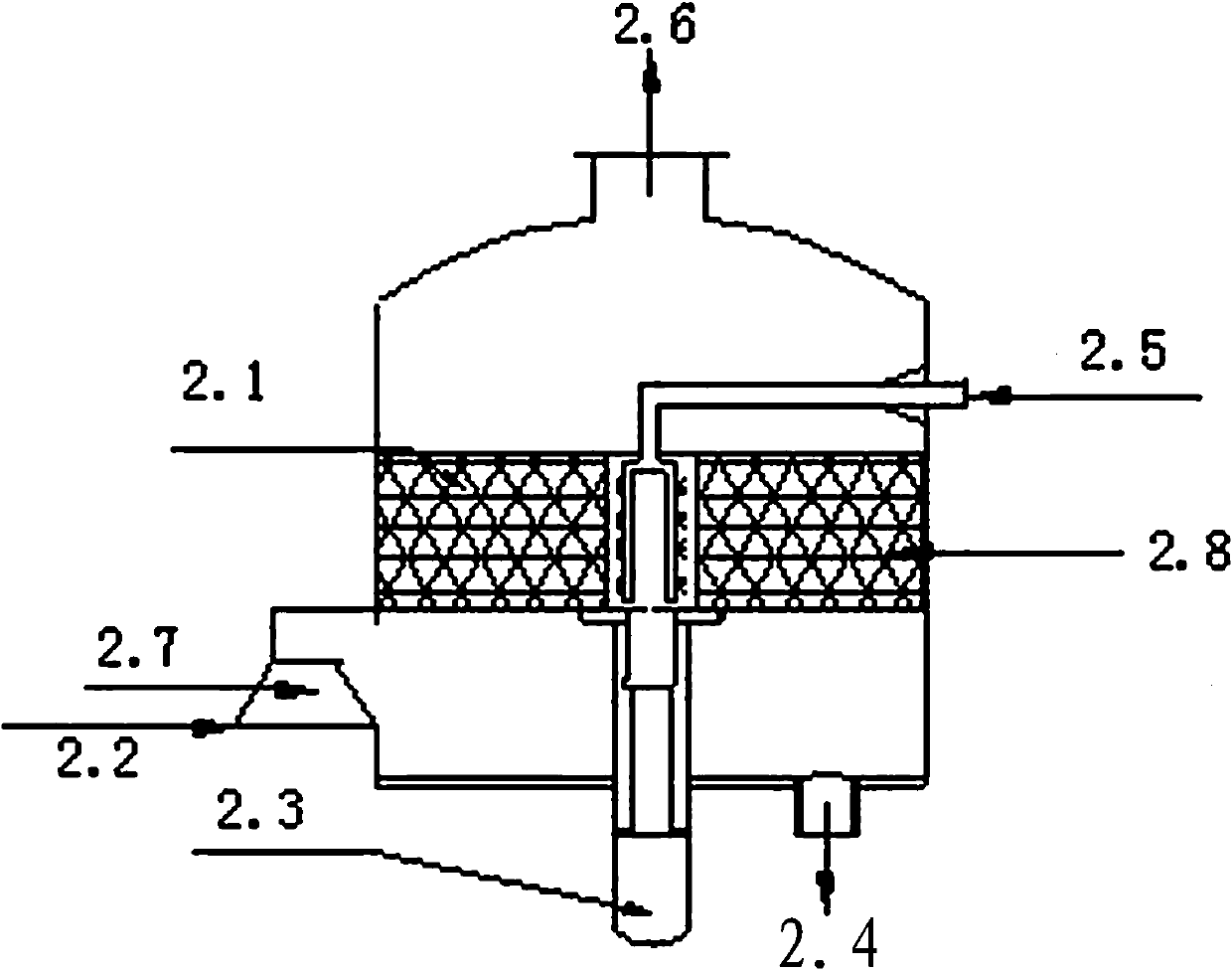

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Take 10L of an industrial ammonium chloride wastewater, the concentration of which is 6% (60g / L). Add 5mol organic amines to the waste water according to the ratio of 0.5mol / L, and use CO 2 Gas distribution with air, where CO 2 The volume fraction is 70%, the gas is in cross-flow contact with the solution, and the liquid circulation per hour is 6 times the liquid volume in the storage tank.

[0022] First, prepare CO with a volume fraction of 70% 2 Gas, turn on the cross-flow rotary packed bed, adjust the frequency converter to make the rotary packed bed speed 3000r / min, start the liquid circulation pump to send the ammonium chloride wastewater to the cross-flow rotary packed bed, open the pressure reducing valve, and send it to the packed bed Pass into the prepared CO 2 For gas, adjust the gas flow meter to keep the liquid-gas ratio at 20L / m 3, circulate for half an hour, stop rotating the packed bed, close the pressure reducing valve, and after the trea...

Embodiment 2

[0023] Embodiment 2: change following conditions, other conditions are the same as embodiment 1. The speed of the high-gravity rotating packed bed is adjusted to 2500r / min, and the liquid-gas ratio is 25L / m 3 . Finally, the conversion rate of ammonium chloride can reach 93%, and the regeneration rate of organic amine can reach 86%.

Embodiment 3

[0024] Embodiment 3: change following conditions, other conditions are the same as embodiment 1. The speed of the high-gravity rotating packed bed is adjusted to 2000r / min, and the liquid-gas ratio is 30L / m 3 . Finally, the conversion rate of ammonium chloride can reach 90%, and the regeneration rate of organic amine can reach 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com