A kind of preparation method of perovskite solar cell

A technology of solar cells and perovskite, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high cost, sensitive film forming conditions, and difficult shape control, etc., and achieves a wide range of applications, crystal The effect of regular grains and large grain fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

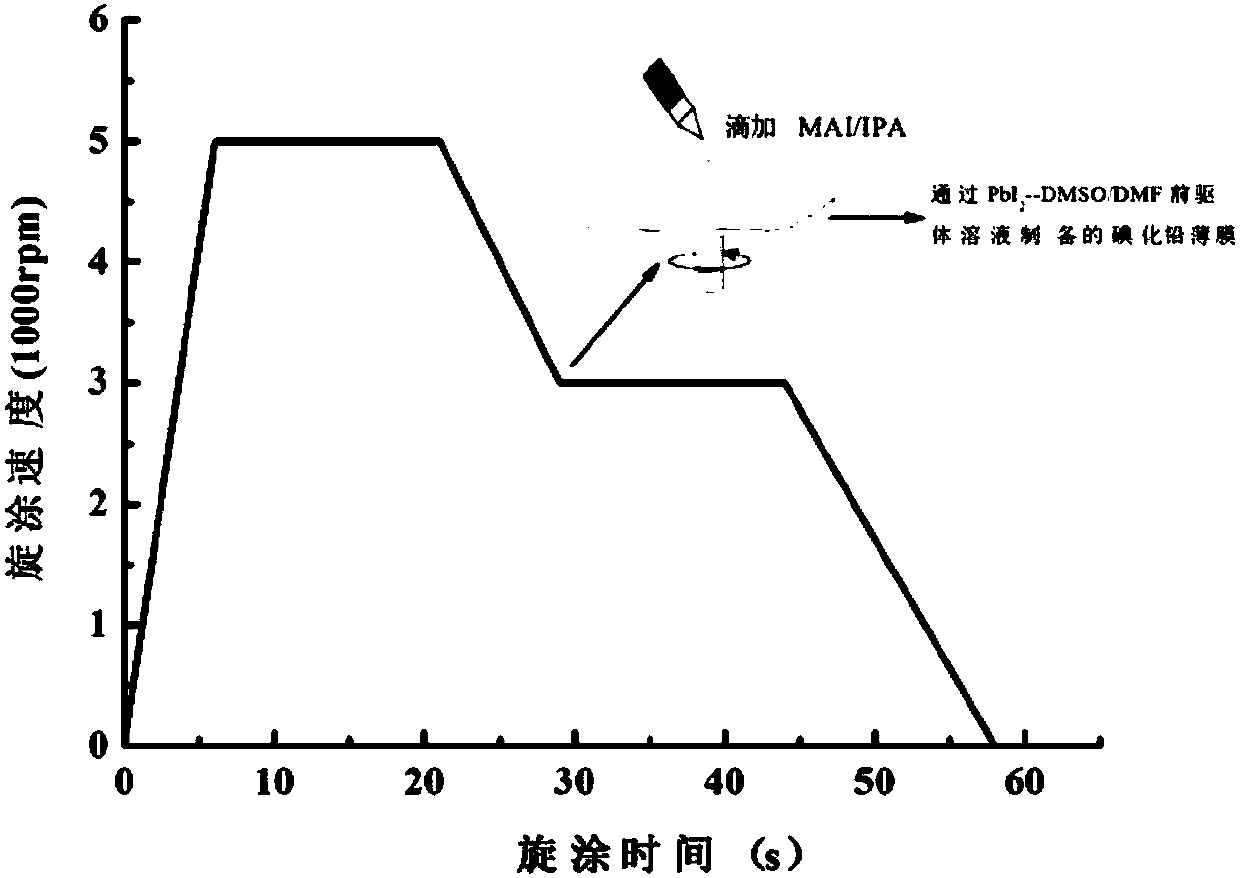

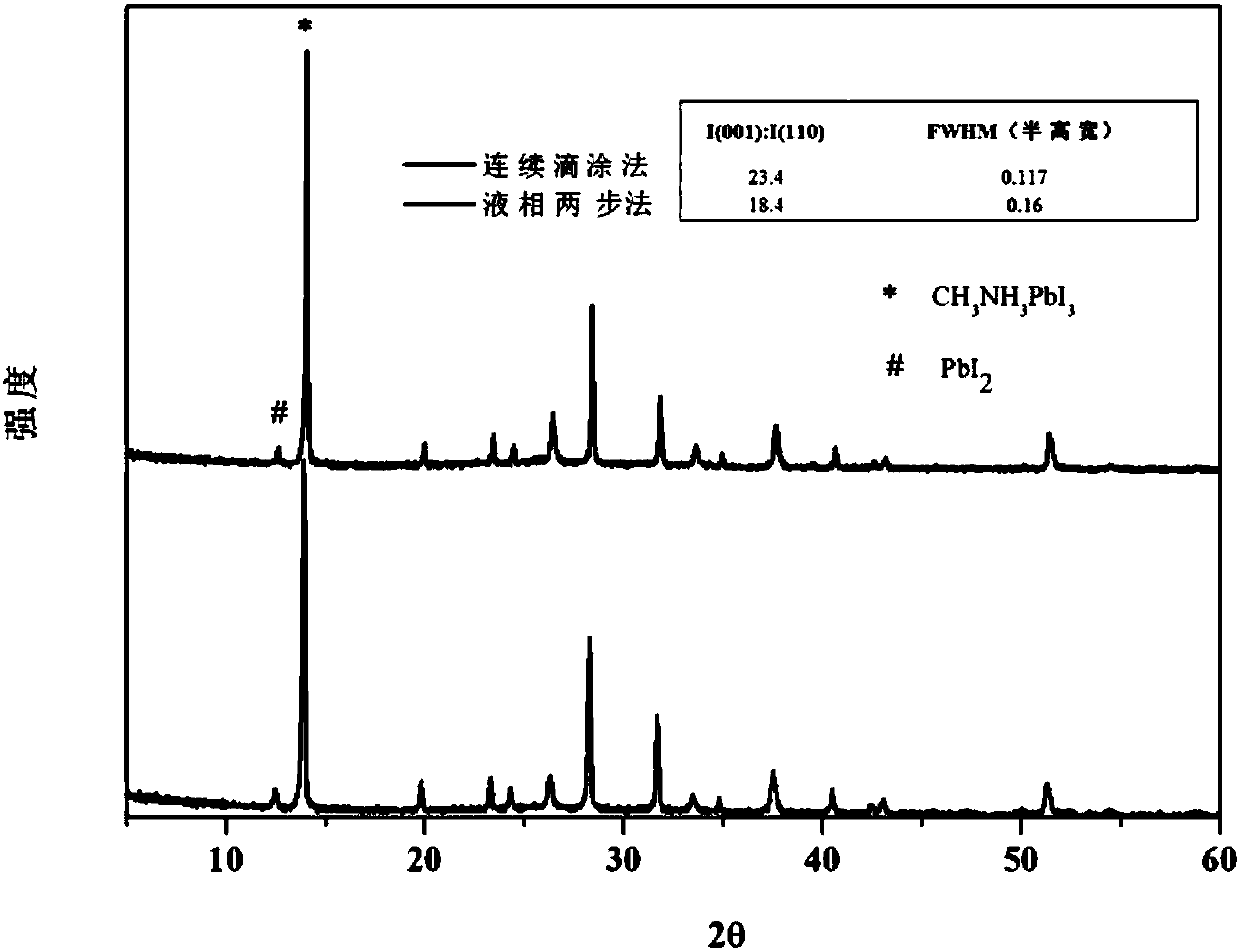

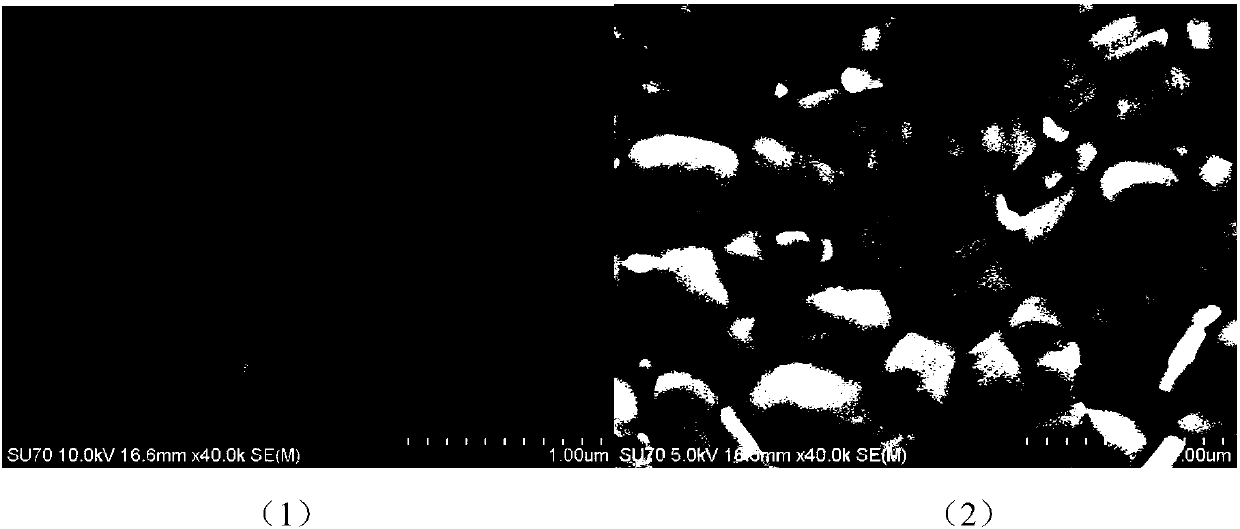

Method used

Image

Examples

Embodiment 1

[0033] (1) FTO (SnO 2 : F) Transparent conductive glass substrate cleaning and oxygen plasma surface treatment: scrub the FTO transparent conductive substrate twice with detergent, then rinse it twice with deionized water, insert it into the cleaning rack, and ultrasonically use acetone and ethanol for 20 minutes in turn . Dry it with a nitrogen gun, and put it into an oxygen plasma cleaner for 15 minutes.

[0034] (2) Spin-coat titanium oxide dense layer: Spin-coat 0.15M n-butanol solution of diisopropoxybisacetylacetonate titanium (titanium diisopropoxidebis(acetylacetonate)) on the oxygen plasma-treated FTO substrate, spin-coating speed The number of spin coatings at 2000rpm was 3 times, and the time for each spin coating was 20s. After each spin coating, the annealing temperature was controlled at 125°C by hot stage annealing for 5 minutes. Then transfer to a muffle furnace for annealing at 500°C for 30 minutes to obtain a substrate A covered with a dense hole blocking l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com