Swivel construction method for large span continuous beam which spans existing station

A technology with existing stations and construction methods, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as large swivel spans, tight construction schedules, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

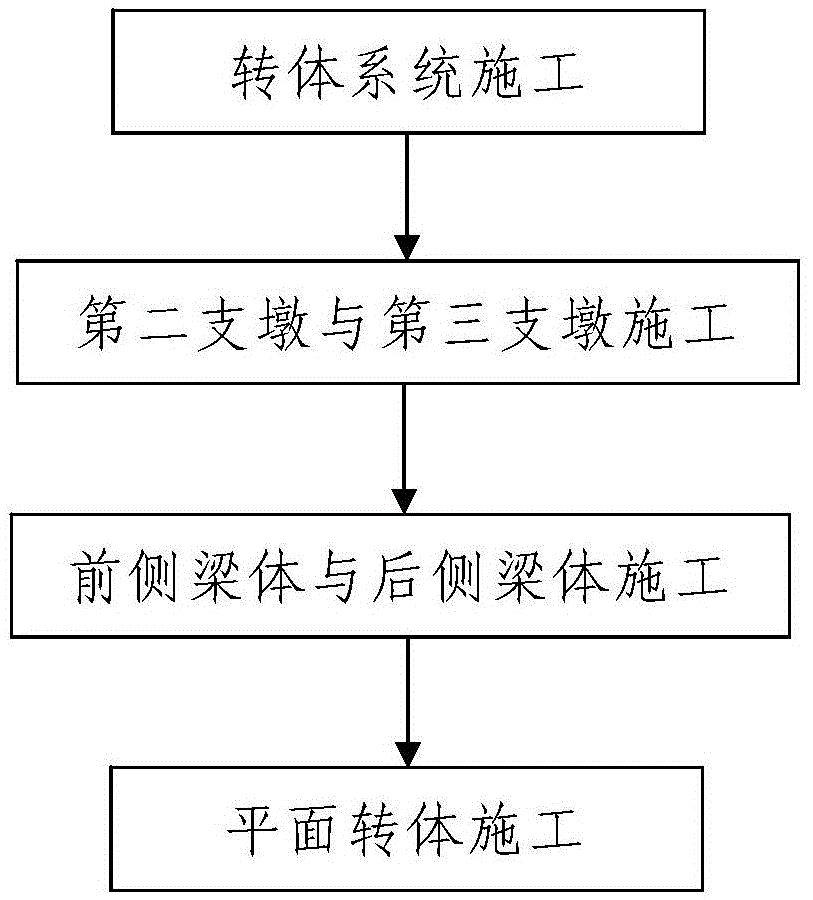

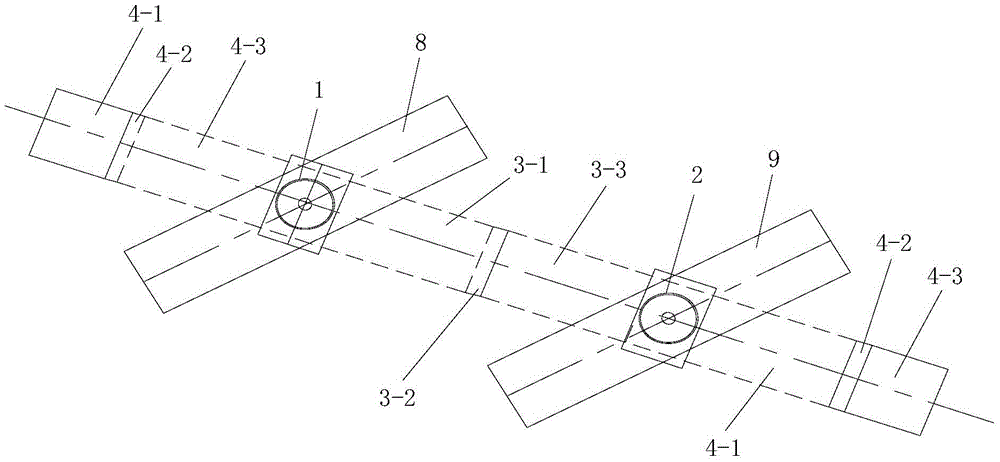

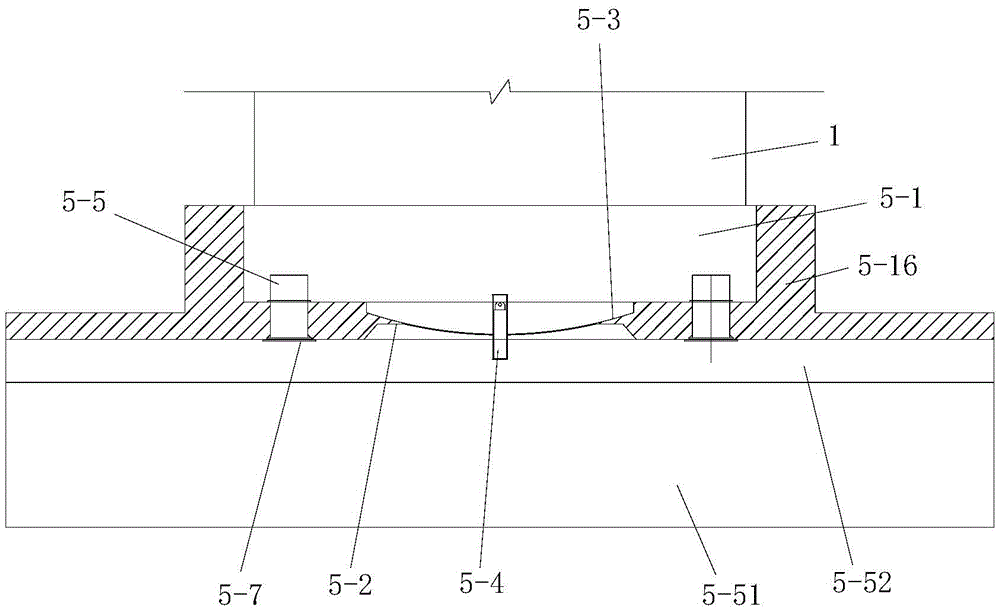

[0101] like figure 1 Shown is a large-span continuous beam spanning the existing station swivel construction method, the long-span continuous beam constructed is a reinforced concrete box girder spanning the existing station; the front and rear ends of the long-span continuous beam are respectively supported on the first On the pier and the fourth pier and the front and rear ends of the span are respectively supported on the second pier 1 and the third pier 2, the first pier, the second pier 1, the third pier 2 and the The fourth pier is laid out from front to back along the longitudinal bridge direction of the large-span continuous beam constructed, and they are all reinforced concrete pier. The second pier 1 and the third pier 2 are respectively located at the two There are left and right sides of the station; the mid-span of the long-span continuous girder constructed is divided into mid-span front side beam section 3-1, mid-span closing section 3-2 and mid-span rear side b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com