Preparation method of leadless antiferroelectric sodium niobate piezoelectric ceramic

A sodium niobate and voltage-electric technology is applied in the field of lead-free anti-ferroelectric ceramic grain control to achieve the effects of excellent ferroelectric performance, low price, and stable process control technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

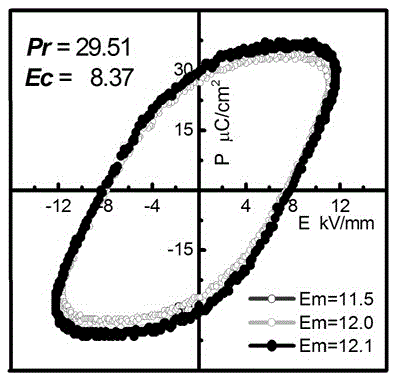

Examples

Embodiment 1

[0030] According to the formula, the chemical formula is NaNbO 3 Weigh the raw materials, the molecular weight is 163.89, and the batching quality is 50.00 grams;

[0031] Weigh the required raw material Na 2 CO 3 Mass is 16.1998 grams, Nb 2 o 5 The mass is 40.7497 grams.

[0032] The preparation method is:

[0033] Weigh Na according to the stoichiometric ratio 2 CO 3 , Nb 2 o 5 After each powder raw material is placed in a ball mill jar, an appropriate amount of absolute alcohol is added as a solvent, and after 24 hours of planetary ball milling, it is at 100 o Dry in the drying box of C temperature for 18 hours, pulverize and pass through 80 mesh sieves, obtain the mixed powder of raw material;

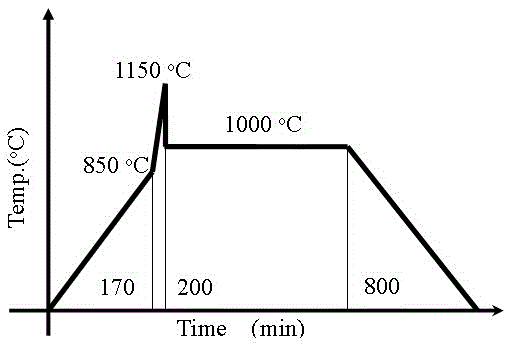

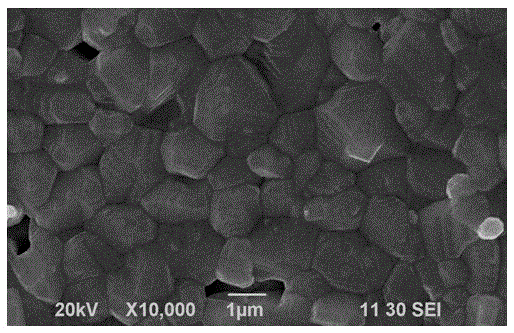

[0034] The resulting mixed powder, after 700 o C, after 6 hours of low-temperature and long-term pre-synthesis, synthesize a mixed powder precursor of about 100 nanometers, such as figure 1 shown;

[0035] To the synthesized precursor powder, add 15wt% of the powder ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com