Device and process for safely treating aluminum phosphide fumigating residues

A safe treatment, aluminum phosphide technology, applied in the direction of solid waste removal, etc., can solve the problems of reducing the absorption effect of the absorption liquid on phosphine, high one-time investment cost, and reduced effective chlorine concentration, so as to reduce the processing burden, Simple structure, the effect of reducing the release peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

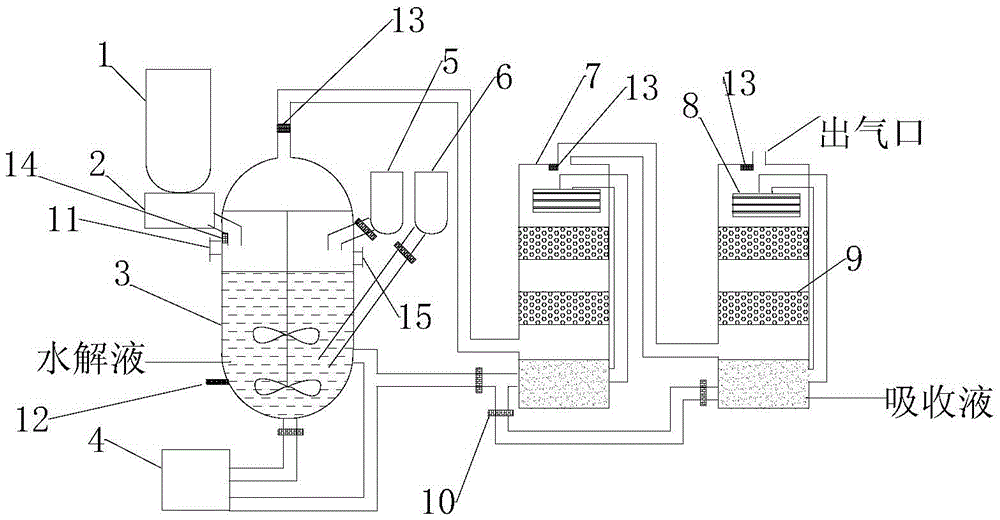

Method used

Image

Examples

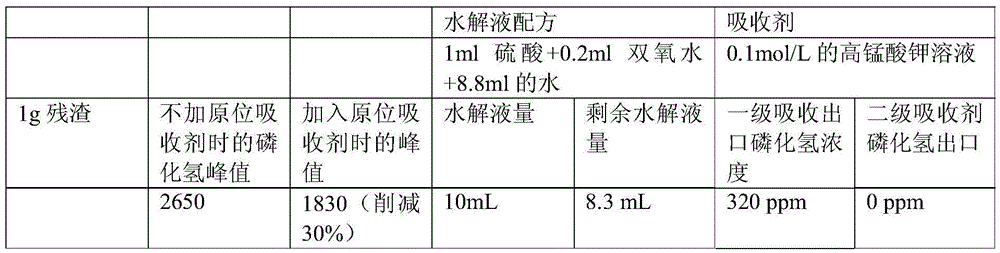

Embodiment 1

[0084] Inject nitrogen into the hydrolysis absorption tank, remove the air in the hydrolysis reaction tank, inject 900ml of water, start the agitator, open the electric water valve and add 50mL of sulfuric acid, start the tail gas absorption device, open the electromagnetic vibrating feeder, feed 100g, open Absorb liquid electric water valve, add hydrogen peroxide 15mL, after hydrolysis reaction for 5 hours, open the electric water valve of the waste liquid discharge port of the hydrolysis absorption tank, the mixed liquid is separated from the solid and liquid by the filter press, and the remaining residue is discharged, and the remaining residue is subjected to the water reaction test It has been verified that the residue no longer has the reaction characteristics, and the residue meets the relevant requirements of the Hazardous Waste Landfill Pollution Control Standard (GB18598-2001) after being neutralized by lime, and can be safely landfilled. The remaining 810mL of hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com