Fragrant health-care skim milk powder and preparation method thereof

A technology of skimmed milk powder and flavor type, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of skimmed milk powder having a light taste, affecting product market sales, and poor palatability, so as to achieve rich taste and fragrance, ensure food safety, Good brewing and solubility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (1) Preparation of diglycerides: put glycerol and duck oil mixed fatty acids in a conical flask at a ratio of 1:0.5 to 3, add 0.5% to 3% of immobilized Candida antarctica lipase B, and then Place it on a shaker, set the temperature at 30°C to 70°C, and set the reaction time at 2 to 12 hours. After the reaction, centrifuge the above reaction solution in a high-speed centrifuge at 4000r / min for 20 minutes to completely separate the enzyme. The obtained supernatant is a high-purity diglyceride mixture.

[0025] (2) Preparation of diglyceride skimmed milk powder emulsion: use 30°C-80°C, 30mL-110mL distilled water to prepare skim milk powder, then add 0.5%-2.5% diglyceride into it, and stir for 30min-150min, Make it emulsified and homogeneous.

[0026] (3) Freeze-drying treatment: the above-prepared emulsion was pre-cooled at -40°C, and then vacuum freeze-dried under the following conditions: -35°C--45°C, 10Pa-15Pa, and the freeze-drying time was 48h.

Embodiment 1

[0027] Embodiment 1: the preparation of scented health-care skimmed milk powder

[0028] (1) Sample preparation

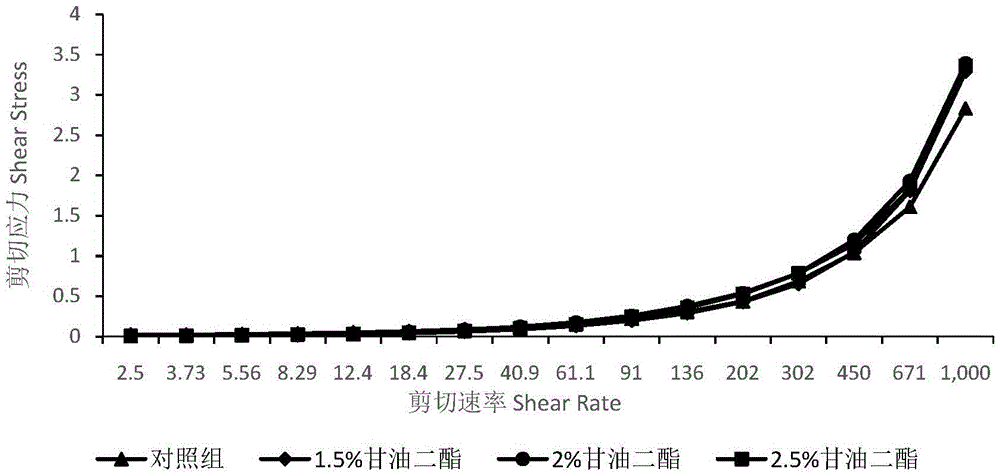

[0029] ①Sample preparation of different addition amounts of duck oil diglyceride: Weigh 9.9g of skimmed milk powder on an electronic balance, then weigh 0.1g of duck oil diglyceride, and prepare it with 70mL60℃~70℃ to contain 1% duck oil glycerin Diesters of skimmed milk powder. Prepare 4 groups of 0.5%, 1.5%, 2%, and 2.5% skimmed milk powder mixtures in the same way.

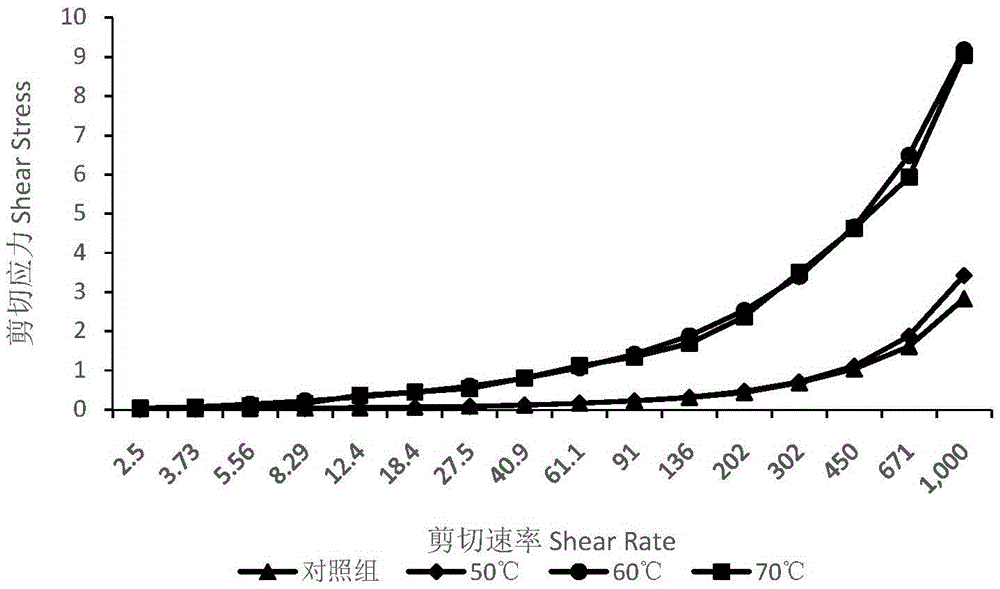

[0030] ②Preparation of samples with different initial water temperatures: the addition amount of diglyceride is 2%, measure 70mL of distilled water at 30°C, 40°C, 50°C, 60°C, 70°C, and 80°C into beakers, and mix the samples evenly .

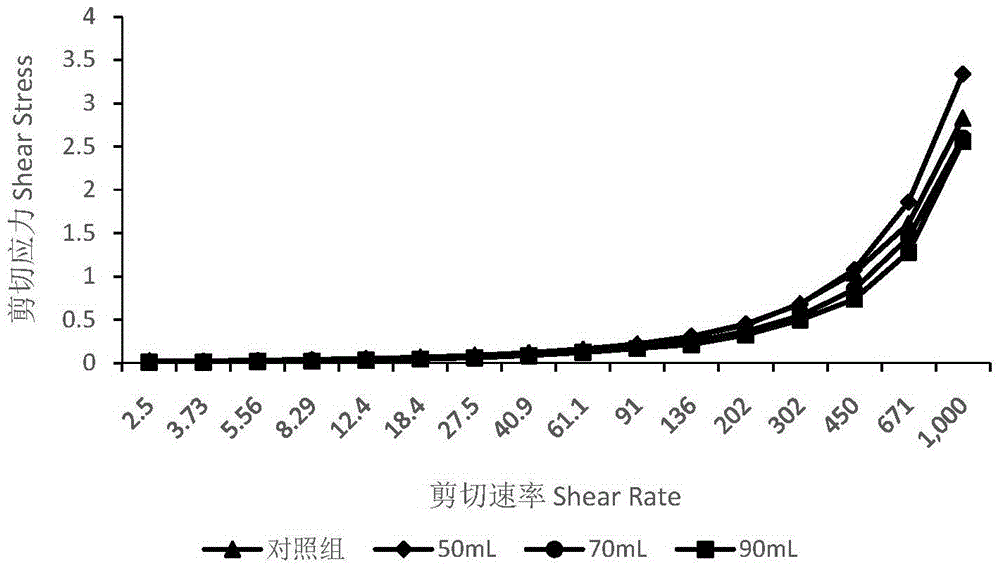

[0031] ③Preparation of samples with different mixing times: add 2% diglyceride, add 70mL of distilled water at 70°C, stir for 30min, 60min, 90min, 120min, and 150min respectively, and make skim milk powder slurries with different stirring times.

[0032] ④Preparati...

Embodiment 2

[0034] Embodiment 2: Determination of the properties of flavored health care skimmed milk powder

[0035] (1) Dispersion determination

[0036] Weigh 10g each of the prepared skim milk powder with an electronic balance, weigh 5 groups, put them into a 100mL beaker, then add 70mL of 65°C distilled water, stir on a constant temperature magnetic stirrer at a certain speed, and record from the beginning of stirring until there is no milk powder in the cup Agglomeration time(s). Calculate the average value of 5 sets of test data.

[0037] (2) Determination of brewability

[0038] Weigh about 5g of prepared duck oil diglyceride skimmed milk powder and pour it into a beaker, dissolve the sample several times with distilled water, transfer it to a 50ml centrifuge tube and centrifuge for 10min, and discard the supernatant. Then add distilled water and shake the centrifuge tube to suspend the precipitate, centrifuge again for 10 minutes, discard the supernatant, put the precipitate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com