High-power thyristor package structure and manufacturing method thereof

A manufacturing method and high-power technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of device product performance decline, low production efficiency, large thermal conduction distance of devices, etc., and reduce thermal conduction distance. , Product performance improvement, the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be further described in detail below. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

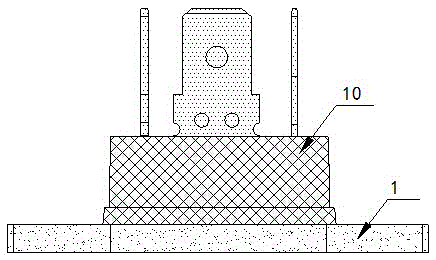

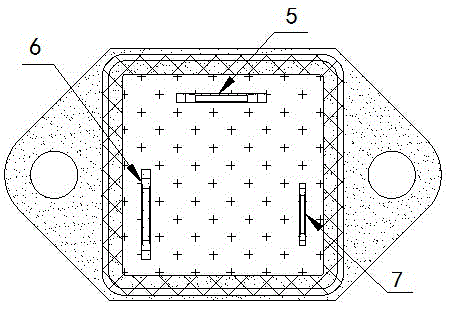

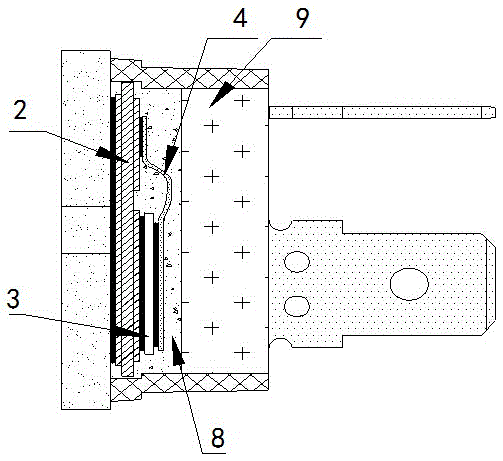

[0036] like Figure 1-4 As shown, a high-power thyristor packaging structure of the present invention includes a metal heat dissipation base plate 1 and a ceramic copper clad laminate 2 whose bottom surface is welded to the upper end of the metal heat dissipation base plate 1. The bottom surface of the ceramic copper clad plate 2 is a large-area copper clad layer. , Figure 6a , Figure 6b , Figure 6c As shown, the top surface of the ceramic copper clad laminate 2 is a copper clad layer divided into the anode welding zone 11, the cathode welding zone 12, and the gate electrode welding zone 13, and the upper end of the ceramic copper clad laminate 2 is sequentially welded with a thyristor chip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com