A Multi-tool Optimal Combination Selection Method for NC Machining with Triangular Mesh Model

A triangular mesh and cutting tool technology, applied in the direction of digital control, program control, electrical program control, etc., can solve problems such as no consideration of impact, low precision, and impact on efficiency, and achieve accurate estimation, high accuracy and robustness , enhance the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

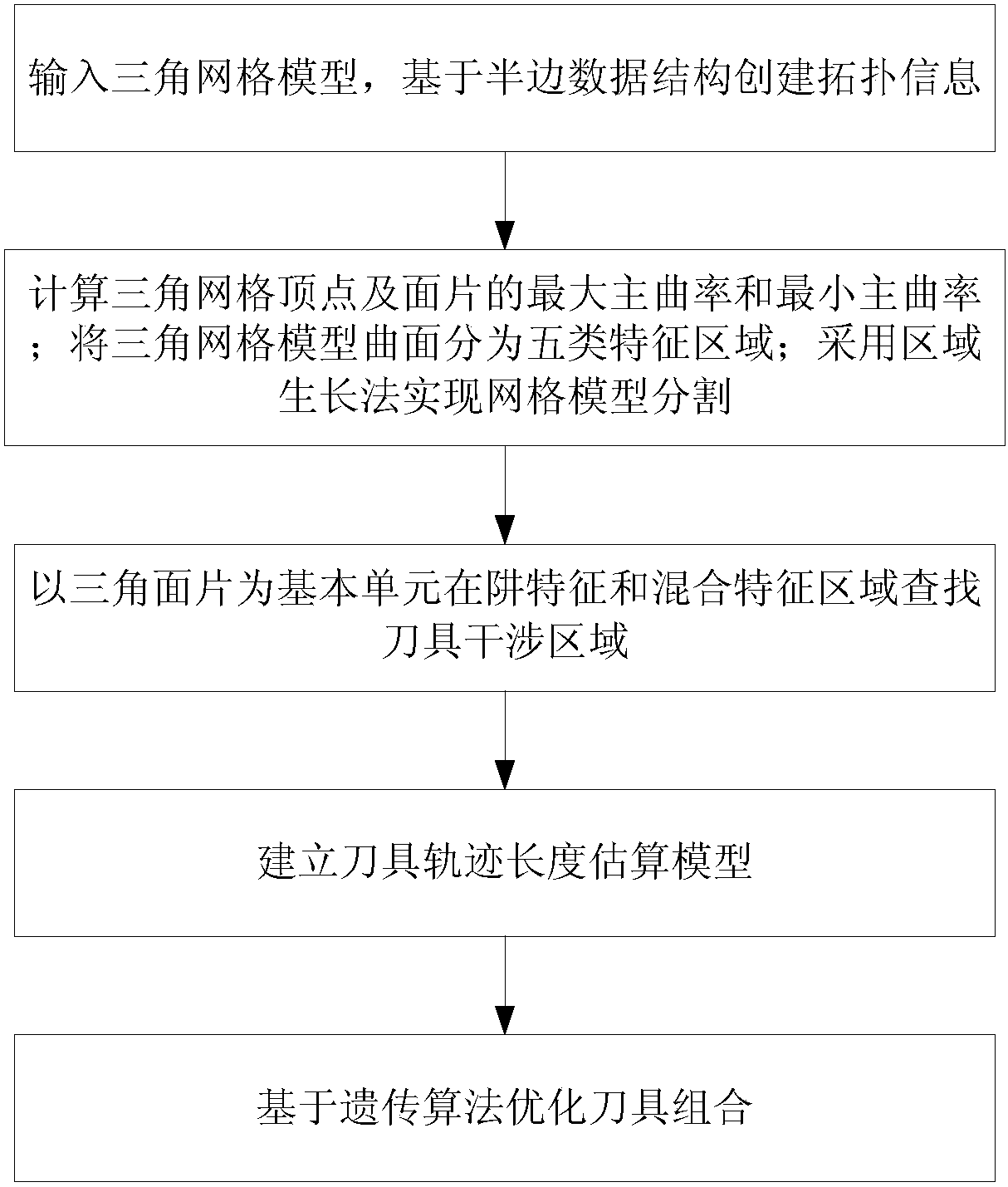

[0062] Such as figure 1 As shown, the method for multi-tool optimal combination selection for CNC machining of a triangular mesh model provided by the present invention is realized by software programming, and specifically includes the following steps:

[0063] Step 1. Read in the triangular mesh model and establish topology information;

[0064] Use the open() function to open the STL (STereo Lithography) triangle mesh model file under the specified path in the hard disk; use fscanf() to read the face vertex data and normal vector data from the text format STL file; read each vertex The data needs to use the collection container class set and associative container class map in the C++ standard template library to remove the point vertices with the same coordinate value, establish a non-redundant point table and surface table, and establish a patch to vertex and vertex to surface Topological adjacency information of the patch; establish a half-edge data structure, create three hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com