Biomass fluidized bed boiler

A fluidized bed boiler and biomass technology, which is applied in the field of boilers, can solve the problems of horizontal air distribution of multi-return flues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

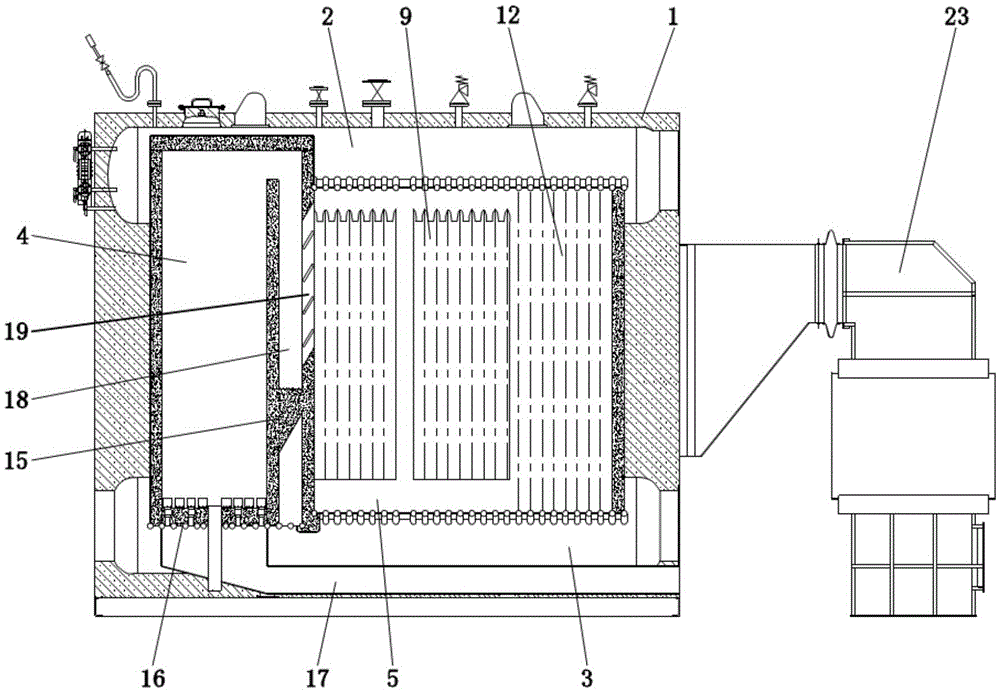

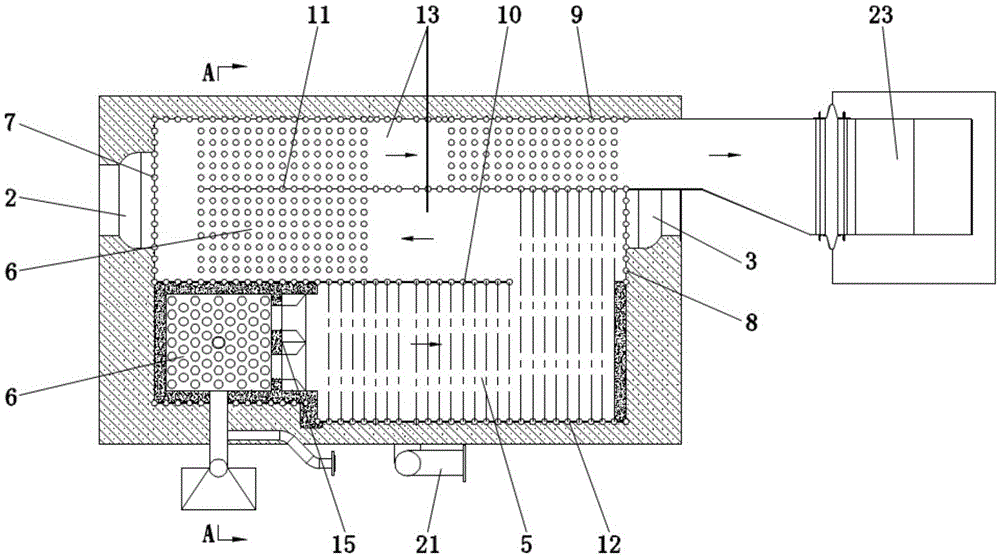

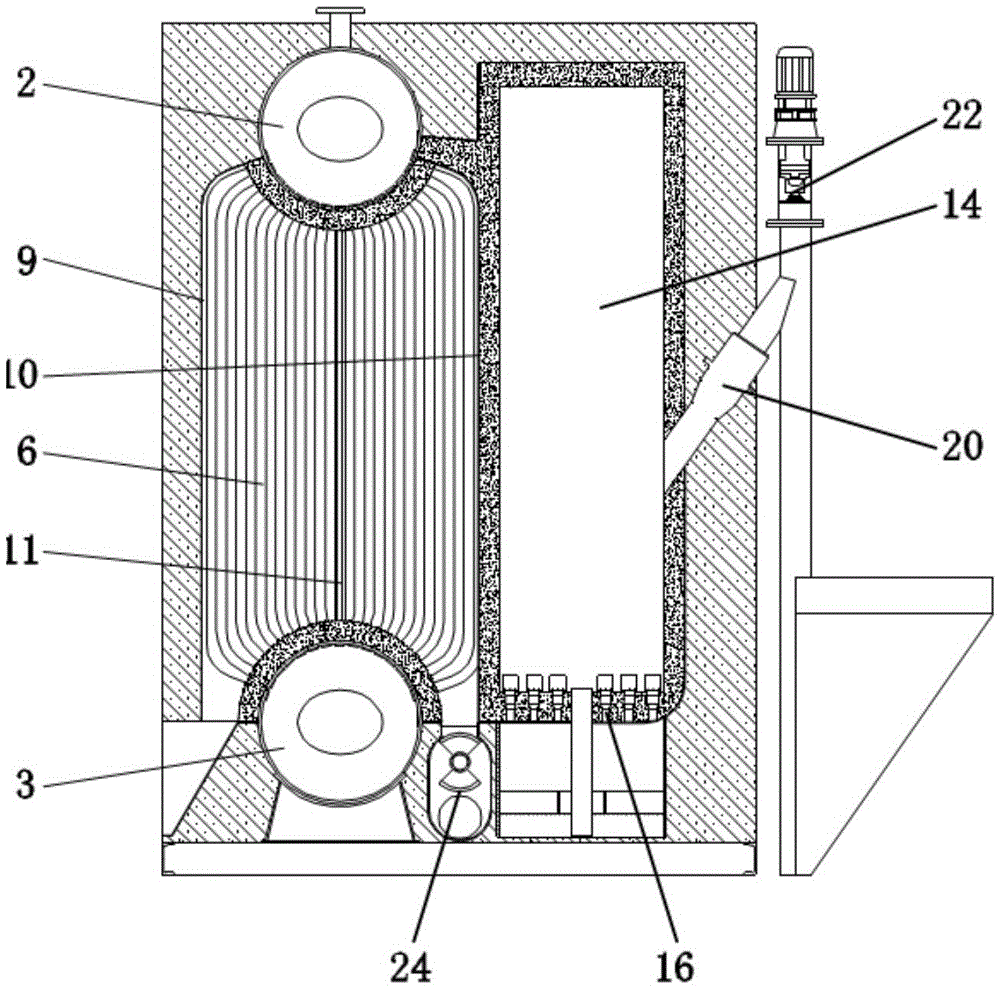

[0023] Such as figure 1 As shown, the biomass fluidized bed is composed of a boiler body, a feed device 22 and an economizer 23 .

[0024] The main body of the boiler is composed of a furnace body 1, an upper drum 2, a lower drum 3, a convection tube bundle 6 and a multi-membrane wall. The upper drum 2 and the lower drum 3 are vertically arranged. The furnace body 1 is mainly an insulating layer, and the outer shell of the insulating layer is wrapped. The inner cavity of the furnace body 1 is provided with a vertical upper drum 2, a vertical lower drum 3, a convection tube bundle 6 and a multi-membrane wall.

[0025] The upper drum 2 and the lower drum 3 are connected with the convection tube bundle 6, the front membrane wall 7, the rear membrane wall 8, the left membrane wall 9 and the right membrane wall 10, the middle membrane wall 11 and the C-shaped membrane wall. wall 12. The front membrane wall 7 and the rear membrane wall 8 are respectively located at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com