Preparation method for paper-based veneer overlaid PVC wood-plastic composite foam floor

A wood-plastic foamed floor, veneer technology, applied in wood layer products, chemical instruments and methods, floors, etc., can solve the problems of lack of natural wood texture and color, difficult to paste, etc., to protect the decorative performance, veneer The effect of low cost and high veneer bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

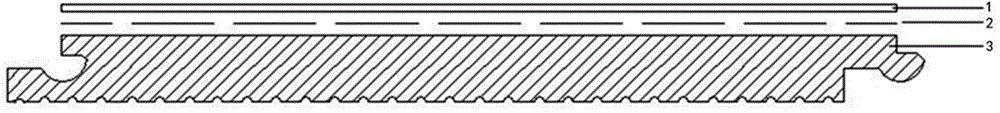

[0018] Specific embodiments, the present embodiment is a kind of preparation method of paper-based thin wood veneer PVC wood-plastic foam floor, carried out according to the following specific steps:

[0019] 1. Pretreatment of PVC wood-plastic foam floor base material. The floor is a PVC wood-plastic foam floor with uniform cell distribution and extruded by a single-screw extruder by adding foaming agent. The specification of the PVC wood-plastic floor base material is 1200mm×138mm×12mm, which is sanded with 200 mesh sandpaper or planed to remove the thermoplastic layer on the surface of the wood-plastic floor to obtain a PVC wood-plastic floor with a smooth surface and a certain roughness. foam floor substrate;

[0020] 2. Prepare paper-based veneer. The paper-based veneer used is a decorative veneer material bonded with kraft paper on the back and solid wood veneer on the front. The thickness of the paper-based veneer is 0.15mm-0.3mm, and the size of the cut paper-based ven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com