Composite stone material and preparation method of same

A technology of stone and artificial stone, applied in the direction of chemical instruments and methods, layered products of hydraulic substances, layered products, etc., can solve the problems of large building energy consumption, large thermal conductivity of stone, etc., achieve low thermal conductivity, reduce Effect of water absorption and shrinkage, good thermal insulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

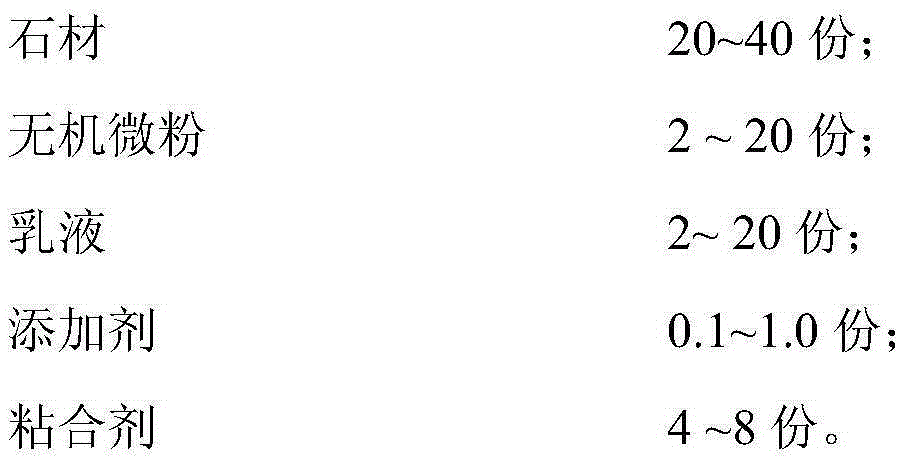

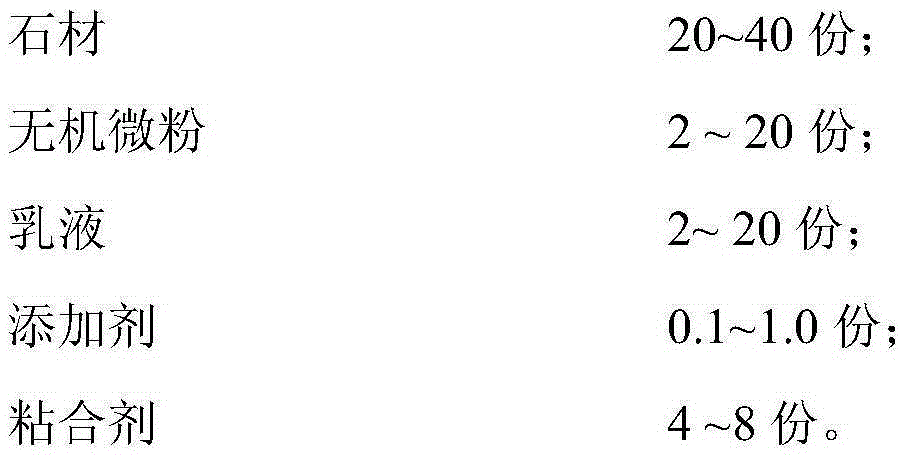

[0024] 1. Weigh the raw materials of each component according to the following formula:

[0025] 25 parts of natural stone, 4 parts of cement, 6 parts of fly ash, 10 parts of potassium silicate solution, 10 parts of water, 0.1 part of turpentine soap, 0.3 parts of organic silicon solution waterproofing agent, 0.2 parts of MgO expansion agent, calcium fluorosilicate speed 0.2 parts of coagulant, 7 parts of epoxy resin. Add the raw materials of each component except natural stone into the mixing pot in turn, first stir slowly for 1-2 minutes, let stand for 5-10 seconds, then stir rapidly for 2-3 minutes, repeat several times, and get the slurry after stirring evenly; The slurry is evenly poured into the mold to install the mold, and the foaming is stopped to obtain the embryo body; then the surface of the embryo body is covered with a plastic wrap, maintained for one day, dried, and then cut and polished to obtain the board layer;

[0026] 2. Preparation of composite stone

[...

Embodiment 2

[0029] 1. Weigh the raw materials of each component according to the following formula:

[0030] 30 parts of organic artificial stone, 5 parts of bentonite, 8 parts of fly ash, 18 parts of sodium silicate solution, 0.2 parts of calcium dodecylbenzenesulfonate, 0.3 parts of acrylic water repellent, 0.2 parts of CaO expansion agent, calcium aluminate fast 0.2 parts of coagulant, 5 parts of sodium aluminosilicate binder. Add the raw materials of each component except organic artificial stone into the stirring pot in turn, first stir slowly for 1-2 minutes, let stand for 5-10 seconds, then stir rapidly for 2-3 minutes, repeat several times, and get the slurry after stirring evenly; Pour the slurry evenly into the mold to install the mold, stop foaming to obtain the embryo body; then cover the surface of the embryo body with a plastic wrap, maintain for one day, dry, and then cut and polish to obtain the board layer;

[0031] 2. Preparation of composite stone

[0032] Bond the bo...

Embodiment 3

[0034] 1. Weigh the raw materials of each component according to the following formula:

[0035] 30 parts of inorganic artificial stone, 5 parts of metakaolin, 8 parts of fly ash, 4 parts of zeolite powder, 18 parts of sodium silicate solution, 2 parts of sodium metaphosphate solution, 0.2 parts of sodium soap, 0.1 part of polyvinyl alcohol waterproofing agent, sulfur aluminum Calcium acid expansion agent 0.21 parts, sodium fluorosilicate quick-setting agent 0.3 parts, polyurethane 8 parts. Add the raw materials of each component except inorganic artificial stone into the mixing pot in turn, first stir slowly for 1-2 minutes, let stand for 5-10 seconds, then stir rapidly for 2-3 minutes, repeat several times, and get the slurry after stirring evenly; Pour the slurry evenly into the mold to install the mold, stop foaming to obtain the embryo body; then cover the surface of the embryo body with a plastic wrap, maintain for one day, dry, and then cut and polish to obtain the boar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com