High-strength and high-toughness blind hole foam aluminum and preparation method thereof

A closed-cell foamed aluminum, high-strength and high-toughness technology, which is applied in the field of high-strength and high-toughness closed-cell aluminum foam and its preparation, can solve the problems of plasticity and toughness decline of composite materials, achieve good cell integrity, improve strength and toughness, The effect of high energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

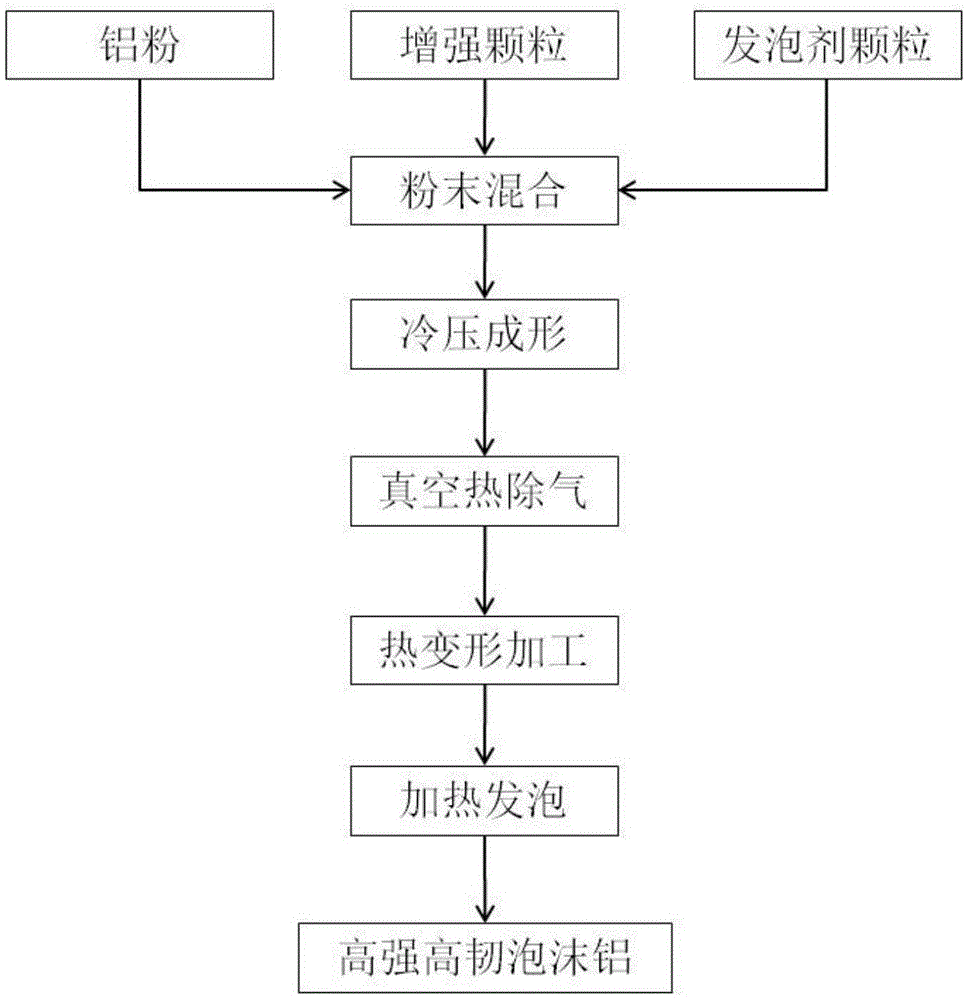

Method used

Image

Examples

Embodiment 1

[0035] The composition of the aluminum foam prepared in this embodiment is 5vol% SiO 2 / Al. The matrix is pure aluminum powder, and the average particle size of pure aluminum powder is 60-70 μm; the reinforcing particles are silicon oxide particles, and the particle volume percentage is 5% (converted to 4.1% by mass), and the average particle size of the reinforcing particles is is 1 μm. The mass percent content of the foaming agent titanium hydride is 0.5%, and the average particle size is 20-40 μm. Weigh 1918g of pure aluminum powder, 82g of silicon oxide powder and 10g of titanium hydride powder, put all the powders into a mixer and mix for 24h. The obtained mixed powder was put into a mold with a diameter of 100m and cold-pressed to form a rough billet. The cold pressing pressure was 100 MPa, and the pressure was maintained for 15 minutes. The relative density of the rough billet was 85%. Put the rough blank into the aluminum sheath, put the aluminum sheath into the d...

Embodiment 2

[0037] The composition of the aluminum foam prepared in this embodiment is 10vol% AlN / 6061Al. The matrix is 6061 aluminum alloy, and the average particle size of the powder is 60-70 μm. The reinforcing particles are aluminum nitride particles, the volume percentage of the particles is 10% (converted to 11.8% by mass), and the average particle size of the reinforcing particles is 4 μm. The mass percent content of the foaming agent titanium hydride is 0.5%, and the average particle size is 20-40 μm. Weigh 1763g of 6061 aluminum alloy powder, 237g of aluminum nitride powder and 10g of titanium hydride powder, put all the powders into a mixer and mix for 24 hours. The obtained mixed powder was put into a mold with a diameter of 100m and cold-pressed to form a rough billet. The cold pressing pressure was 100 MPa, and the pressure was maintained for 15 minutes. The relative density of the rough billet was 82%. Put the rough blank into the aluminum sheath, put the aluminum sheath...

Embodiment 3

[0039] The composition of the aluminum foam prepared in this embodiment is 25vol%Al 2 o 3 / 4047Al. The matrix is 4047Al alloy, and the average particle size of the powder is 60-70 μm. The reinforcing particles are alumina particles, the volume percentage of the particles is 25% (converted to 32.4% by mass), and the average particle size of the reinforcing particles is 20 μm. The mass percent content of the foaming agent titanium hydride is 0.2%, and the average particle size is 20-40 μm. Weigh 1351g of 4047Al alloy powder, 649g of alumina powder and 4g of titanium hydride powder, put all the powders into a mixer and mix for 24 hours. The obtained mixed powder was put into a mold with a diameter of 100m and cold-pressed to form a rough billet. The cold pressing pressure was 150 MPa, and the pressure was maintained for 15 minutes. The relative density of the rough billet was 78%. Put the rough blank into the aluminum sheath, put the aluminum sheath into the degassing furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com