Preparation method of biomass fuel and special device thereof

A biomass fuel and hard technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low production efficiency, dryer waste, environmental pollution, etc., to save costs, ensure production efficiency, and burn calorific value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples.

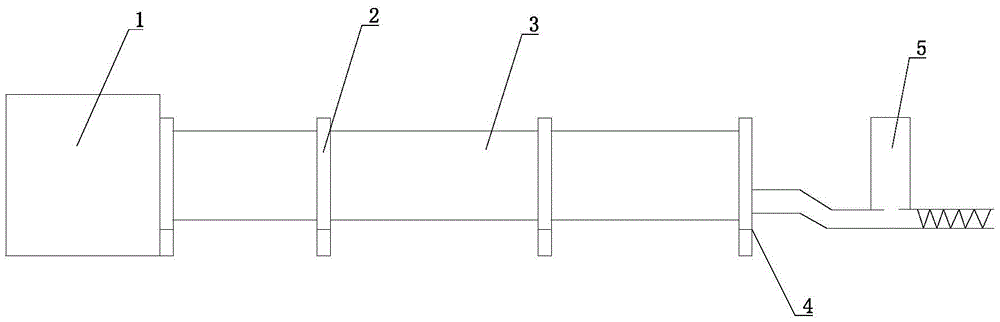

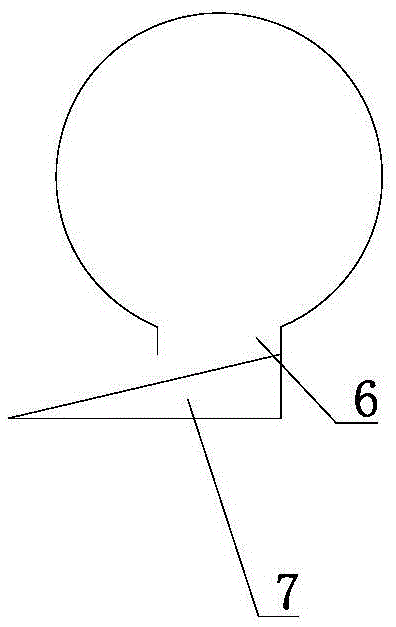

[0019] Such as figure 1 with figure 2 As shown, the wood residue dryer used in the present invention for removing hard impurities is provided with a heating chamber 1, a feeder 2, a drying cylinder 3 and an exhaust fan 5, and one end of the drying cylinder 3 is connected to the heating chamber 1, The other end is connected to the exhaust fan 5; the drying cylinder 3 is provided with a feeder 2. By setting the waste discharge hole 4, the waste discharge pipe 6 and the waste discharge rack 7 at the discharge end of the drying cylinder 3, the hard impurities that have been at the bottom during the drying and rotating process can be removed, thereby reducing the abnormality of the subsequent pressing abrasive wear and tear, saving costs and ensuring production efficiency.

[0020] The discharge rack 7 is a U-shaped groove with a slope, which is convenient for the concentrated disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com