High-temperature and high-pressure kettle transition vehicle for laminated glass

A high-temperature, high-pressure, laminated glass technology, which is applied to the external frame, packaging of vulnerable items, packaging, etc., can solve the problems of large area occupied by the production site, poor operation safety, and slow transfer speed, so as to reduce equipment investment and reduce electric energy The effect of low consumption and rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

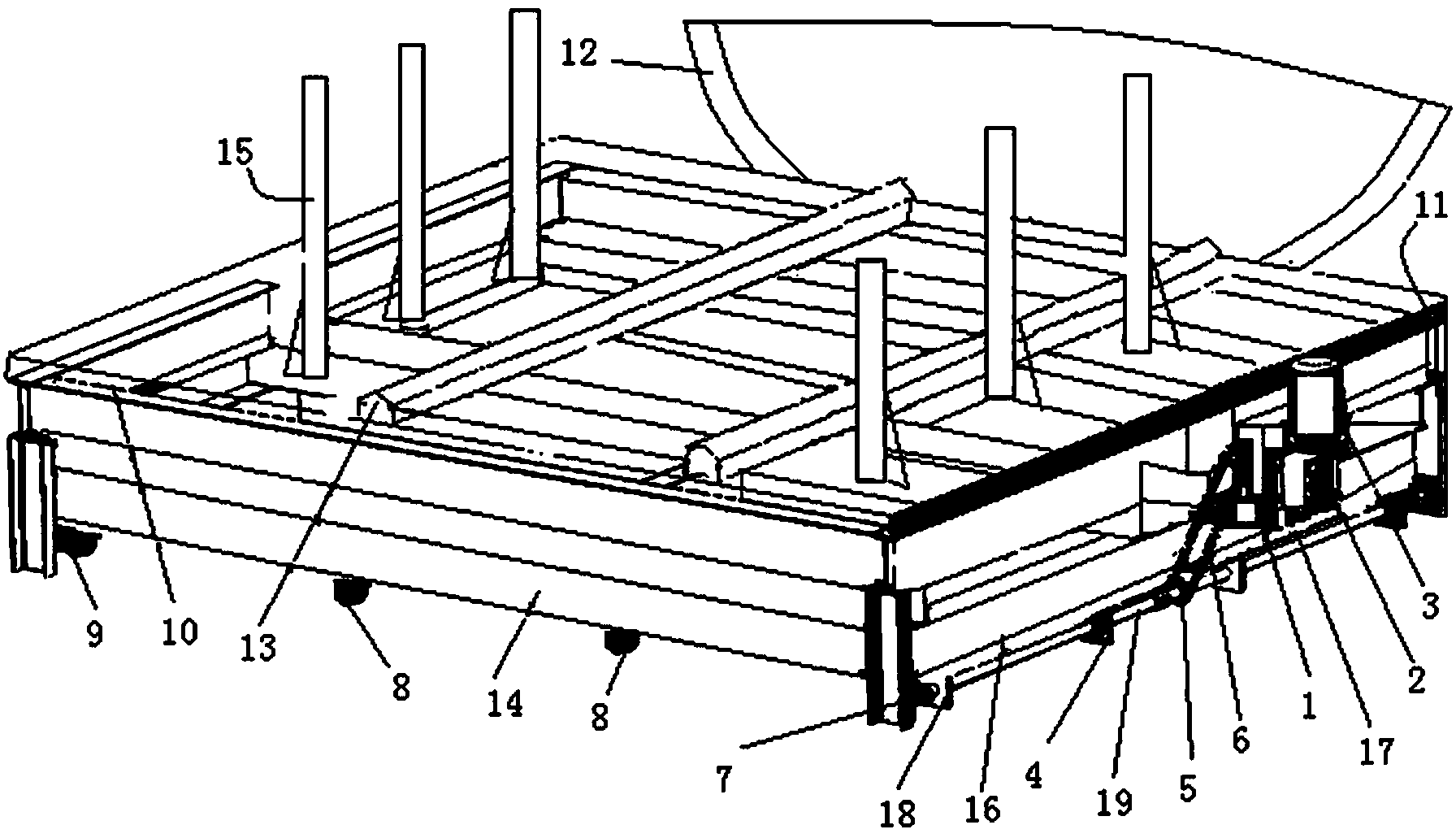

[0020] Such as figure 1 As shown, a high-temperature and autoclave transition car for laminated glass includes a car chassis, and the four corners of the bottom of the chassis are respectively provided with side support frames 7, and the side support frames 7 are connected to the surrounding horizontal support beams 16 and longitudinal support beams 14. A bearing seat is provided at the support frame 7 at the lower part of the cross support beam 16. The bearing seat is provided with a connecting shaft 19 that matches the inner ring of the bearing. The two ends of the connecting shaft 19 are respectively matched with the inner hole of the bearing. The two ends of the side support frame 7 are provided with moving wheels 18, 9 that can rotate together with the connecting shaft, and the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com