Novel transmission mechanism of cutting machine tool

A technology of cutting machine tools and transmission mechanisms, which is applied in metal processing and other directions, can solve the problems of easily damaged transmission mechanisms, and achieve the effects of overcoming complex structures, less abnormal wear and long service life

Inactive Publication Date: 2013-12-18

XUZHOU KAILONG MINING SCI & TECH DEV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Beneficial effects: Since the present invention adopts a rotating transmission shaft and adds a magnetic steel elastic shaft to the rotating transmission shaft, the two transmission mechanisms have a mutual compensation structure, so that the overall transmission mechanism has a simple structure, less abnormal wear, The advantages of good use effect and long service life effectively overcome the defects of complex structure, abnormal wear and easy damage of the transmission mechanism of the existing cutting machine tool

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

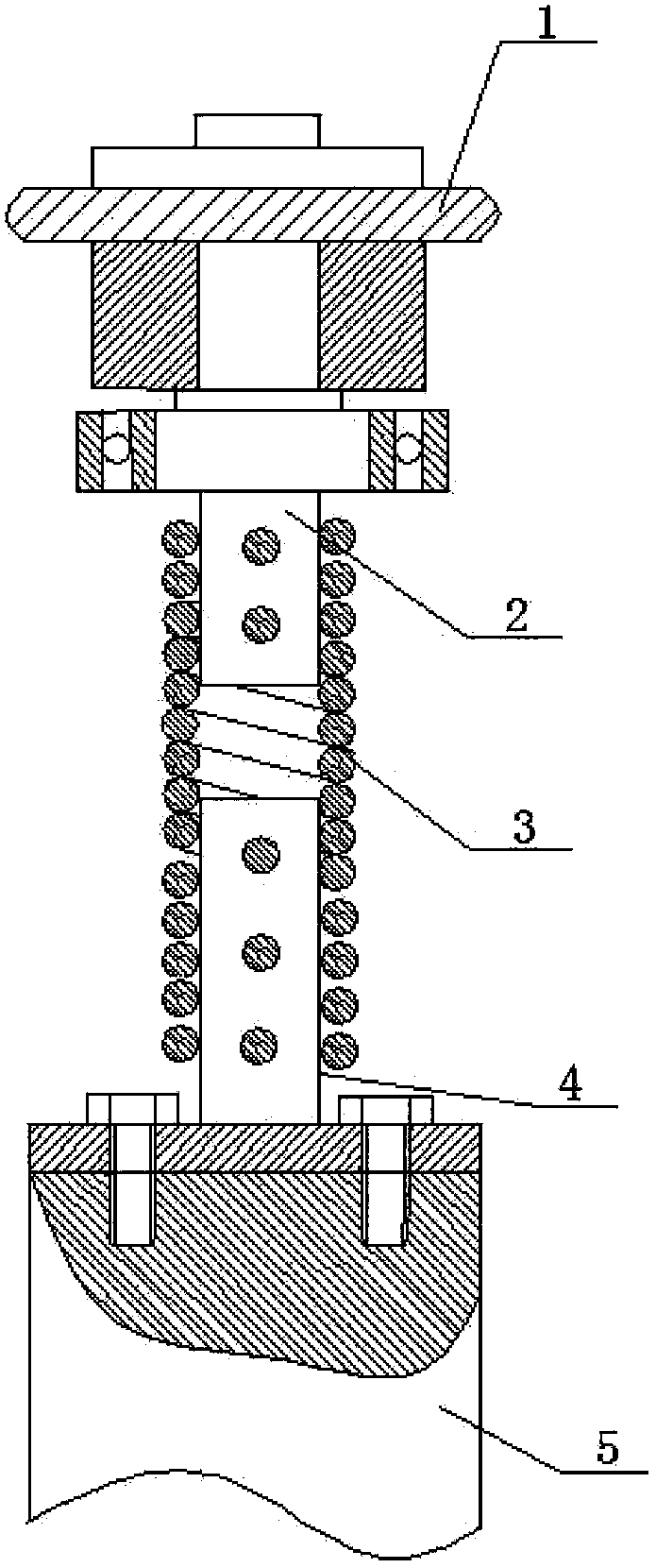

[0009] The transmission mechanism of the cutting machine tool has a transmission sprocket (1), the transmission sprocket (1) is concentrically installed on the transmission sprocket shaft (2), and the tail of the transmission crankshaft (5) is concentrically installed on the rotating transmission shaft (4). The transmission sprocket shaft (2) is connected with the rotating transmission shaft (4) by a magnetic steel elastic shaft (3).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel transmission mechanism of a cutting machine tool. The novel transmission mechanism is characterized in that a transmission sprocket is concentrically mounted on a transmission sprocket shaft, the tail of a transmission crankshaft is concentrically mounted on a rotary transmission shaft, and the transmission sprocket shaft is connected with the rotary transmission shaft by a magnetic steel elastic shaft. The novel transmission mechanism in the structural mode is provided with the rotary transmission shaft, the magnetic steel elastic shaft is additionally arranged on the rotary transmission shaft, two transmission mechanisms are mutually compensatory, and accordingly the integral novel transmission mechanism has the advantages of simple structure, little abnormal abrasion, good service effect and long service life.

Description

technical field [0001] The invention relates to a transmission mechanism, in particular to a novel cutting machine tool transmission mechanism, which belongs to the technical field of cutting machine tool transmission. Background technique [0002] During the power transmission process of the cutting machine tool, the crankshaft transmits the power to the sprocket through the transmission shaft, and the motion of the crankshaft is synchronously transmitted to the cam controller through the sprocket. The degree error is very small, which increases the difficulty of the cutting machine tool. If the center of the crankshaft and the center of the sprocket are not concentrically too large, the movement of the crankshaft will cause the drive shaft to break. Therefore, the current cutting machine tool transmission mechanism has The structure is complicated, the abnormal wear is large and the transmission mechanism is easily damaged. Contents of the invention [0003] The pur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q5/00

Inventor 张胜凯

Owner XUZHOU KAILONG MINING SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com