A kind of ultra-high temperature salt-resistant drilling fluid and preparation method thereof

A drilling fluid and ultra-high temperature technology, applied in the field of water-based drilling fluid, can solve the problems of borehole diameter shrinkage, difficulty in controlling fluid loss, affecting construction quality and construction cost, etc. Easy to control, apply great effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

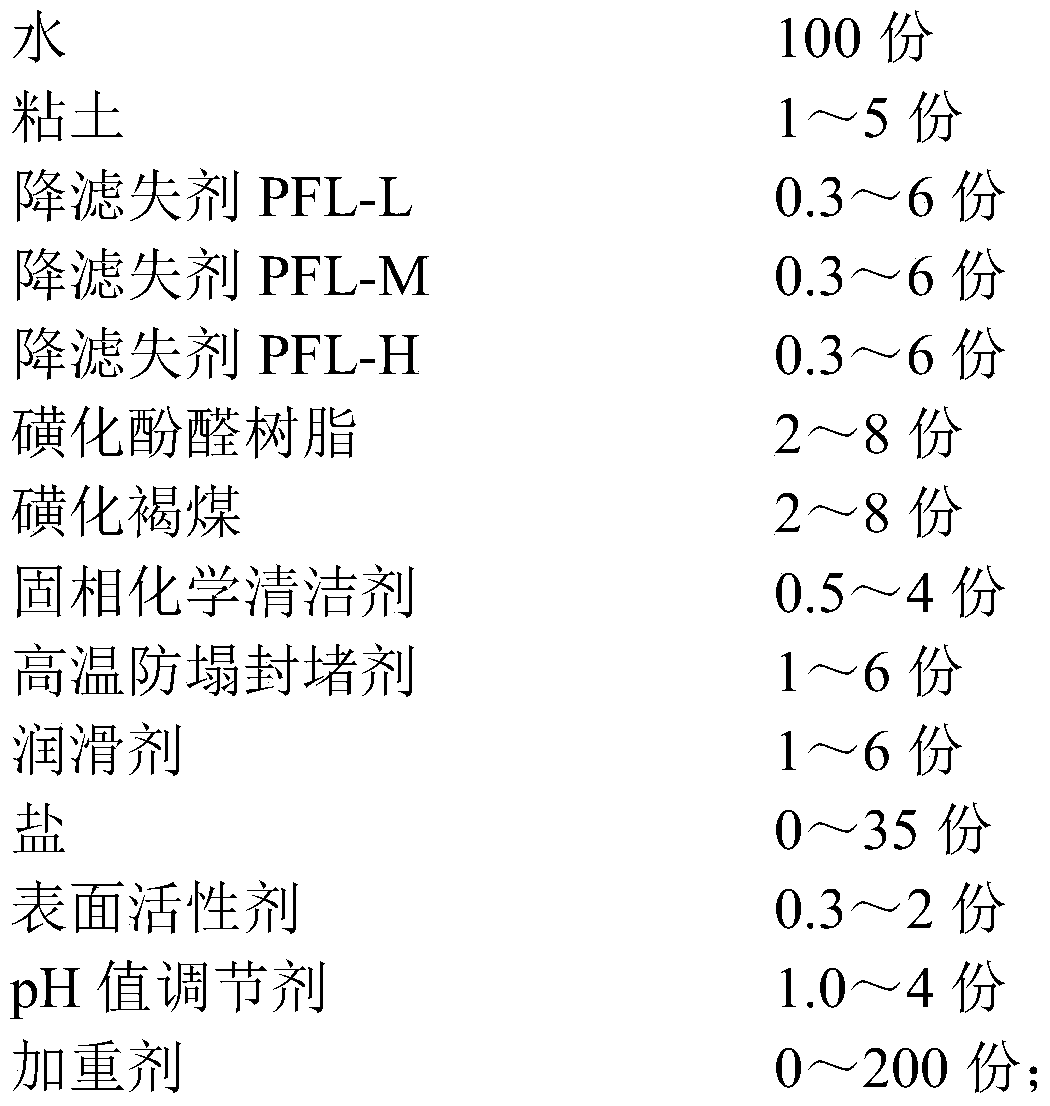

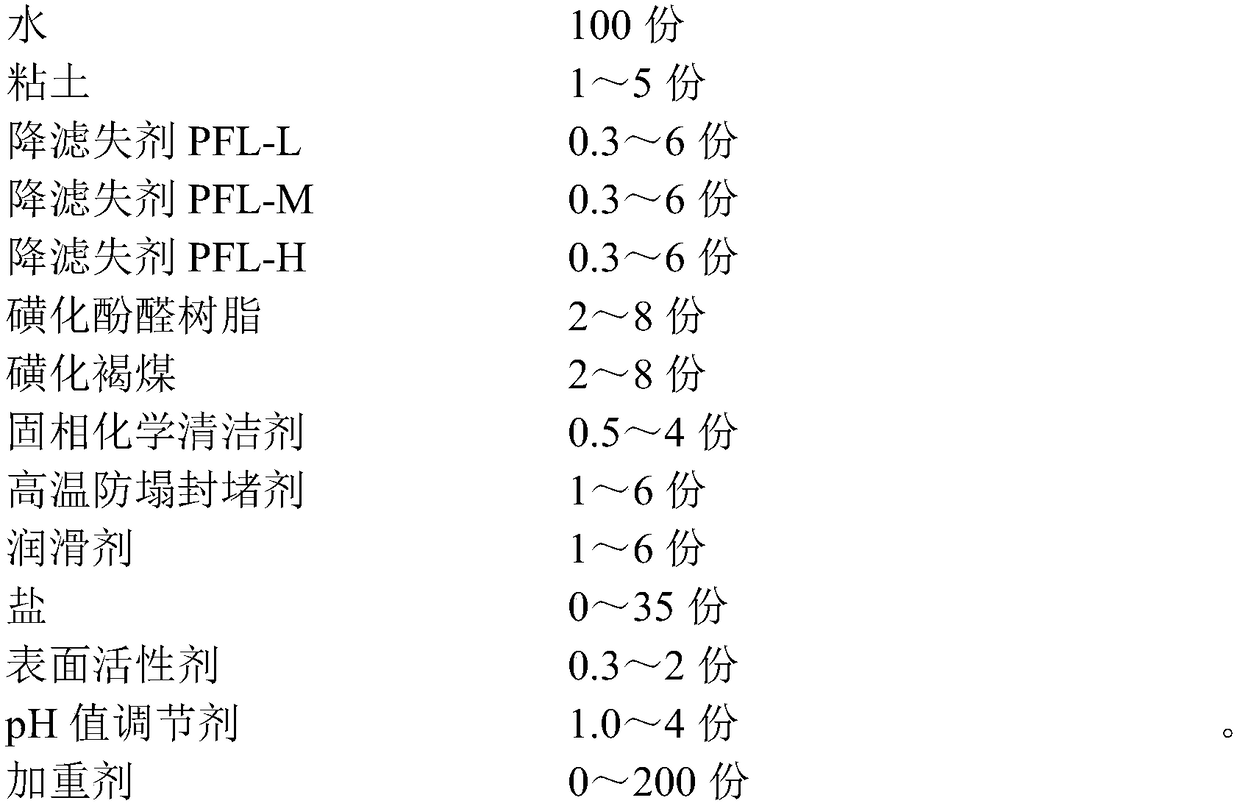

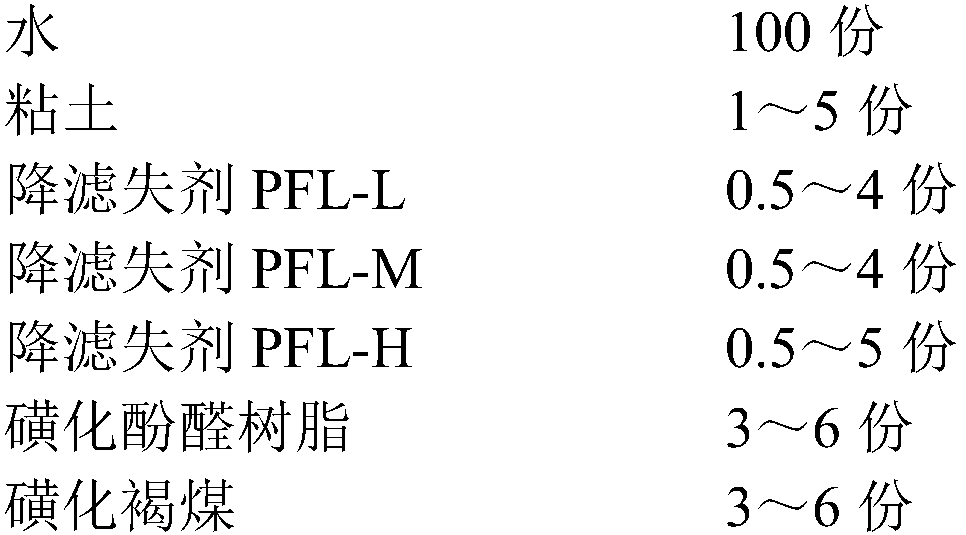

Method used

Image

Examples

Embodiment 1

[0044] Add 0.8g of sodium carbonate to 400g of water, add 16g of sodium bentonite after the dissolution is complete, stir at high speed for 20 minutes, then place it in airtight room temperature for 24 hours. Add 4g of fluid loss additive PFL-H, 6g of fluid loss additive PFL-M, and 2g of fluid loss additive PFL-L in sequence under high stirring, and then add 8g of sulfonated phenolic resin SMP- Type II, 8g sulfonated lignite, 3g solid phase chemical cleaner ZSC-201, 12g sulfonated bitumen HQ-10, 8g lubricant SMJH-1, 1.2g sorbitan monooleate, 5g sodium hydroxide, add Stir at high speed for 20 minutes after completion, add 60g barite, stir at high speed for 10 minutes, measure rheological properties and medium pressure water loss, roll at 260°C for 16 hours, cool down to room temperature, stir at high speed for 5 minutes, measure rheological properties, medium pressure Water loss under pressure and high temperature and high pressure water loss at 180°C.

[0045] Drilling fluid ...

Embodiment 2

[0049] Add 0.7g of sodium carbonate to 400g of water, add 14g of sodium bentonite after the dissolution is complete, stir at high speed for 2 minutes, then place it in airtight room temperature for 24 hours. Add 6g of fluid loss additive PFL-H, 4g of fluid loss additive PFL-M, 4g of fluid loss additive PFL-L in sequence under high stirring, and then add 12g of sulfonated phenolic resin SMP- Type II, 12g sulfonated lignite, 3g solid phase chemical cleaner ZSC-201, 12g sulfonated bitumen HQ-10, 6g lubricant SMJH-1, 1.5g sorbitan monooleate, 6g sodium hydroxide, add Stir at high temperature for 20 minutes after completion, then add 260g of barite, stir at high speed for 10 minutes, measure rheological properties and medium pressure water loss, roll at 260°C for 16 hours, cool down to room temperature, stir at high speed for 5 minutes, measure rheological properties, Medium pressure water loss and high temperature and high pressure water loss at 180°C.

[0050] Drilling fluid pro...

Embodiment 3

[0053] Add 0.6g of sodium carbonate to 400g of water, add 12g of sodium bentonite after the dissolution is complete, stir at high speed for 20 minutes, then place it at room temperature for 24 hours in an airtight place. Add 6g of fluid loss agent PFL-H, 3g of fluid loss agent PFL-M, 6g of fluid loss agent PFL-L in turn under high stirring, and add 16g of sulfonated phenolic resin SMP- Type II, 16g sulfonated lignite, 5g solid phase chemical cleaner ZSC-201, 10g sulfonated bitumen HQ-10, 4g lubricant SMJH-1, 1.5g sorbitan monooleate, 8g sodium hydroxide, 30g After adding potassium chloride, stir at high speed for 20 minutes, then add 260g of barite, stir at high speed for 10 minutes, measure rheological properties and medium pressure water loss, roll at 240°C for 16 hours, cool down to room temperature, stir at high speed for 5 minutes, Measure rheological properties, medium pressure water loss and high temperature and high pressure water loss at 180°C.

[0054] Drilling flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com