Low-density water base drilling fluid capable of resisting ultra-high temperature of 248 DEG C as well as preparation method and application thereof

A water-based drilling fluid, low-density technology, used in chemical instruments and methods, earth-moving drilling, flushing wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

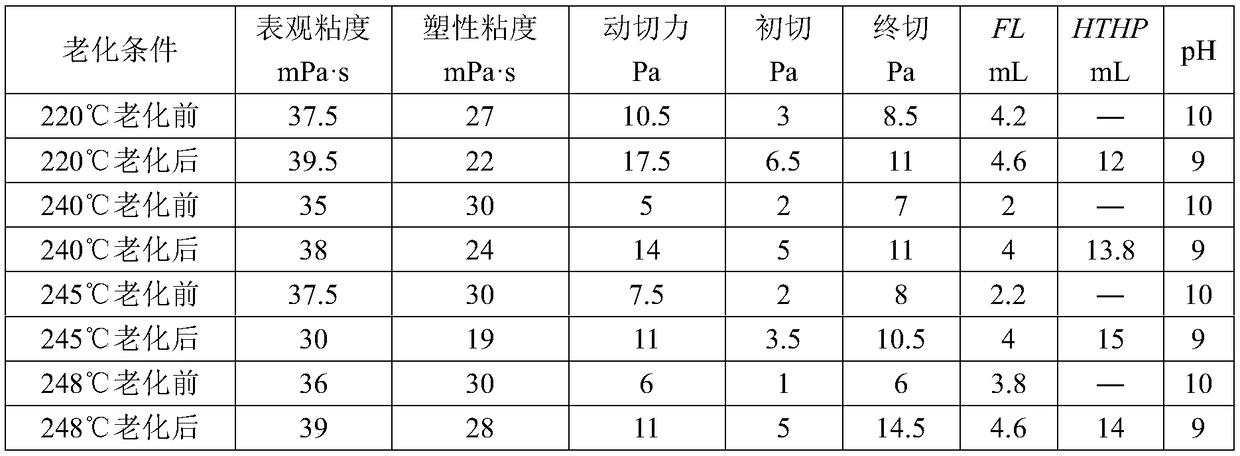

Examples

Embodiment 1

[0092] 1.1 Drilling fluid formula composition: 400mL mixing water + 8g sodium bentonite + 0.4g sodium carbonate + 0.6g flaky sodium hydroxide + 2g anhydrous sodium sulfite + 2g ultra-high temperature resistant compound salt high relative molecular weight amphoteric ion hydrophobic association polymerization Fluid loss reducer + 2.8g ultra-high temperature salt-resistant anionic polymer fluid loss reducer + 12g sulfomethylated phenolic resin + 15g sulfomethyl lignite resin + 12g high softening point sulfonated asphalt + 6g modified Graphite lubricant + 8g polymer alcohol + 6g No. 5 white oil + 1.2g Span 80 + 6g anti-ultra-high temperature polycarboxylate flow regulator + 20g ultra-fine calcium carbonate + barite weighted to 1.10g / cm 3 .

[0093] 1.2 Preparation method: Add 400mL of mixing water into a high stirring cup, under the condition of high-speed stirring (8000~12000rpm), add 8g of sodium bentonite, 0.4g of sodium carbonate and 0.6g of flake sodium hydroxide in sequence,...

Embodiment 2

[0108] As described in Example 1, the difference is the composition of the drilling fluid and the density of the drilling fluid.

[0109] 2.1 Drilling fluid formula composition: 400mL mixing water + 16g sodium bentonite + 0.8g sodium carbonate + 1.2g flaky sodium hydroxide + 2.0g anhydrous sodium sulfite + 2.0g ultra-high temperature resistant compound salt high relative molecular weight amphoteric ion hydrophobic Polymer fluid loss reducer+2.0g ultra-high temperature salt-resistant anionic polymer fluid loss reducer+12g sulfomethylated phenolic resin+17g sulfomethyl lignite resin+12g high softening point sulfonated asphalt+ 6g modified graphite lubricant + 6g polymer alcohol + 6g No. 5 white oil + 1.2g Span 80 + 2.0g anti-ultra-high temperature polycarboxylate flow regulator + 20g ultra-fine calcium carbonate + barite weighted to 1.04g / cm 3 .

[0110] 2.2 Preparation method: Add 400mL of mixing water into a high stirring cup, under the condition of high-speed stirring (800...

Embodiment 3

[0115] As described in Example 1 and Example 2, the difference is the composition of the drilling fluid and the density of the drilling fluid.

[0116] 3.1 Drilling fluid formula composition: 400mL mixing water + 8g sodium bentonite + 0.4g sodium carbonate + 1.2g flaky sodium hydroxide + 2g anhydrous sodium sulfite + 2.8g ultra-high temperature resistant compound salt high relative molecular weight amphoteric ion hydrophobic association Polymer fluid loss reducer + 2.4g ultra-high temperature anti-salt medium relative molecular weight anionic polymer fluid loss reducer + 16g sulfomethylated phenolic resin + 16g sulfomethyl lignite resin + 12g high softening point sulfonated asphalt + 4g Modified graphite lubricant + 8g polyalcohol + 4g No. 5 white oil + 1.2g Span 80 + 4g anti-ultra-high temperature polycarboxylate flow regulator + 20g ultra-fine calcium carbonate + barite weighted to 1.30g / cm 3 .

[0117] 3.2 Preparation method: Add 400mL of mixing water into a high stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com