Preparation method of nano-SiO2 modified alkyd resin

A kind of alkyd resin and nano technology, applied in the direction of coating, polyester coating, etc., can solve the problems of resin viscosity increase, nano particle agglomeration, precipitation, etc., and achieve the effect of excellent hardness and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

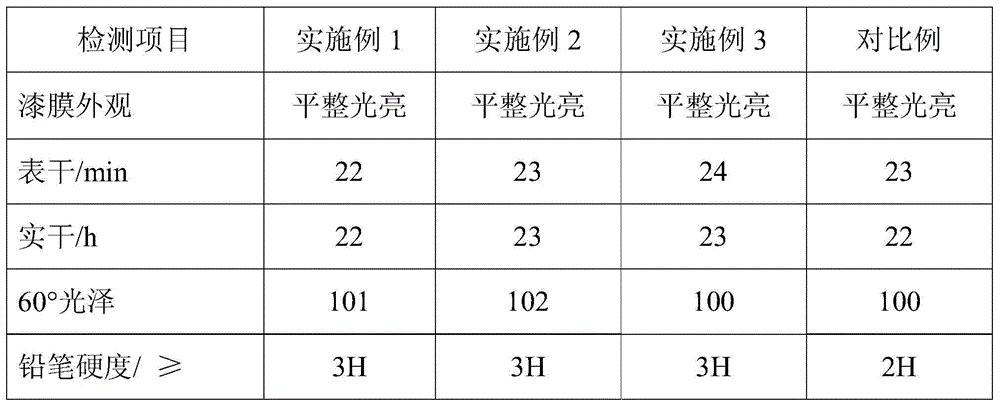

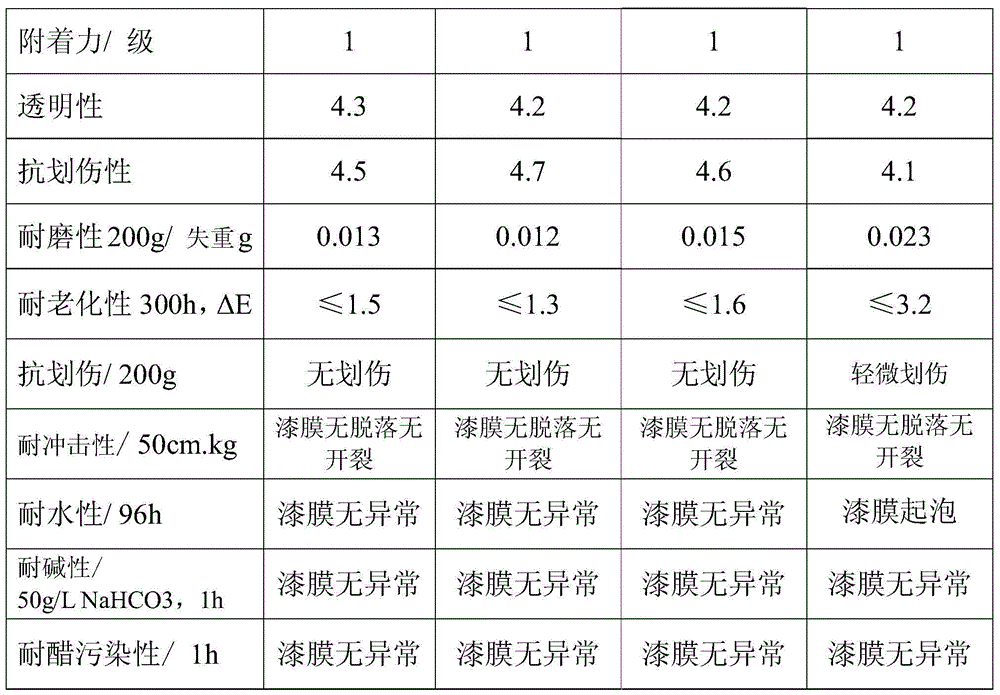

Examples

Embodiment 1

[0019] A kind of nano-SiO 2 Modified lauric alkyd resin, its preparation method, comprises the steps:

[0020] a. In a container with ultrasonic waves, add 5 parts of nano-SiO by weight percentage 2 And 6 parts of neopentyl glycol, control the ultrasonic frequency of 1000kHz to react for 1h, and prepare nano-SiO 2 Alcohol dispersion, spare;

[0021] b. Equipped with agitator, condenser, N 2 In the synthesis kettle of the gas inlet, feed port, discharge port, oil-water separator, thermometer and sampling device, add 51 parts of lauric acid, 26 parts of phthalic anhydride, 12 parts of trimethylol propanol and 11 parts of nano-SiO 2 Alcohol dispersion, pass N 2 When the temperature is raised to 120°C, add 0.016 parts of LiOH catalyst and 5 parts of xylene as a reflux solvent. After the temperature is raised to 170°C and kept for 1.5 hours, the temperature is raised to 210°C at 10°C / h and kept for 2 hours until the acid value is 2 Modified lauric alkyd resin.

Embodiment 2

[0023] A kind of nano-SiO 2 Modified coconut oil alkyd resin, its preparation method, comprises the steps:

[0024] a. In a container with ultrasonic waves, add 4 parts of nano-SiO by weight percentage 2 And 6 parts of neopentyl glycol, control the ultrasonic frequency of 1000kHz to react for 1h, and prepare nano-SiO 2 Alcohol dispersion, spare;

[0025] b. Equipped with agitator, condenser, N 2 Add 52 parts of coconut oil acid, 13 parts of phthalic anhydride, 13 parts of isophthalic acid, and 12 parts of trimethylol in the synthesis kettle of gas inlet, feed port, discharge port, oil-water separator, thermometer and sampling device in sequence. propanol and 10 parts nano-SiO 2 Alcohol dispersion, pass N 2 When the temperature is raised to 120°C, add 0.018 parts of LiOH catalyst and 5 parts of xylene as a reflux solvent, heat up to 170°C and keep it warm for 1.5 hours, then raise the temperature to 220°C at 10°C / h, keep it warm for 2 hours, until the acid value 2 Modified...

Embodiment 3

[0027] A kind of nano-SiO 2 Modified soybean oil alkyd resin, its preparation method, comprises the steps:

[0028] a. In a container with ultrasonic waves, add 6 parts of nano-SiO by weight percentage 2 And 6 parts of neopentyl glycol, control the ultrasonic frequency of 1000kHz to react for 1h, and prepare nano-SiO 2 Alcohol dispersion, spare;

[0029] b. Equipped with agitator, condenser, N 2 In the synthesis kettle of the gas inlet, feed port, feed port, oil-water separator, thermometer and sampling device, add 50 parts of soy oil, 20 parts of phthalic anhydride, 6 parts of benzoic acid, 12 parts of trimethylolpropanol and 12 parts Nano SiO 2 Alcohol dispersion, pass N 2 When the temperature is raised to 120°C, add 0.02 parts of LiOH catalyst and 5 parts of xylene as a reflux solvent. After the temperature is raised to 170°C and kept for 1.5 hours, the temperature is raised to 210°C at 10°C / h and kept for 2 hours until the acid value is less than 12mgKOH / g. Cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com