Modified polyether amine curing agent and preparation method and application thereof

A polyetheramine and curing agent technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of complex preparation process of curing agent, high viscosity of curing agent, difficult reaction control, etc., and achieve easy popularization and application, gel time Long, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

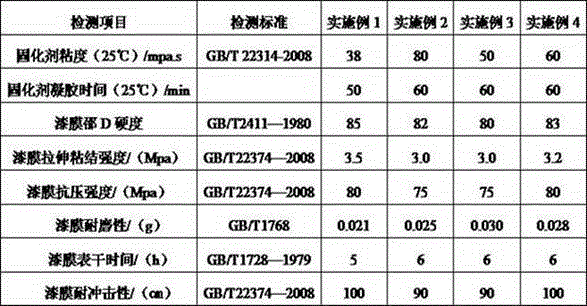

Examples

Embodiment 1

[0027] S1. Pour 50 parts of polyetheramine curing agent D-230 into the reaction kettle, stir at a speed of 300 rpm at room temperature, add 25 parts of phenolic synergistic additive nonylphenol and 15 parts of 2,4 , 6-tris(dimethylaminomethyl)phenol, reacted for 2 hours;

[0028] S2. Add 10 parts of benzyl alcohol and raise the temperature to 50°C to continue the reaction for 2 hours, then stop the heating, and evacuate to 300Pa to obtain a light yellow transparent liquid, which is the modified polyetheramine curing agent.

Embodiment 2

[0030] S1. Pour 45 parts of polyetheramine curing agent D-230 into the reaction kettle, stir at a speed of 500 rpm at room temperature, add 30 parts of phenolic synergistic additive dodecylphenol and 10 parts of 2 , 4,6-tris(dimethylaminomethyl)phenol, reacted for 1.5 hours;

[0031] S2. Add 15 parts of benzyl alcohol and raise the temperature to 50°C to continue the reaction for 1 hour, then stop heating, and evacuate to 300Pa to obtain a light yellow transparent liquid, which is the modified polyetheramine curing agent.

Embodiment 3

[0033] S1. Pour 40 parts of polyetheramine curing agent D-400 into the reaction kettle, stir at a speed of 400 rpm at room temperature, add 20 parts of phenolic synergistic additive nonylphenol and 5 parts of 2,4 , 6-tris(dimethylaminomethyl)phenol, reacted for 1 hour;

[0034] S2. Add 20 parts of benzyl alcohol and raise the temperature to 45°C to continue the reaction for 2 hours, then stop the heating, and evacuate to 300Pa to obtain a light yellow transparent liquid, which is the modified polyetheramine curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com