Nitrogen-doped porous graphite and preparation method thereof

A technology of porous graphene and nitrogen doping, applied in the field of nanomaterials, can solve the problems of difficult large-scale preparation, complex preparation process, destruction of two-dimensional structure, etc., and achieve the effects of easy satisfaction of method conditions, low process cost, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment relates to a method for preparing nitrogen-doped porous graphene with a high specific surface area, which is economical, scalable and has a narrow pore size distribution. The method comprises the following steps:

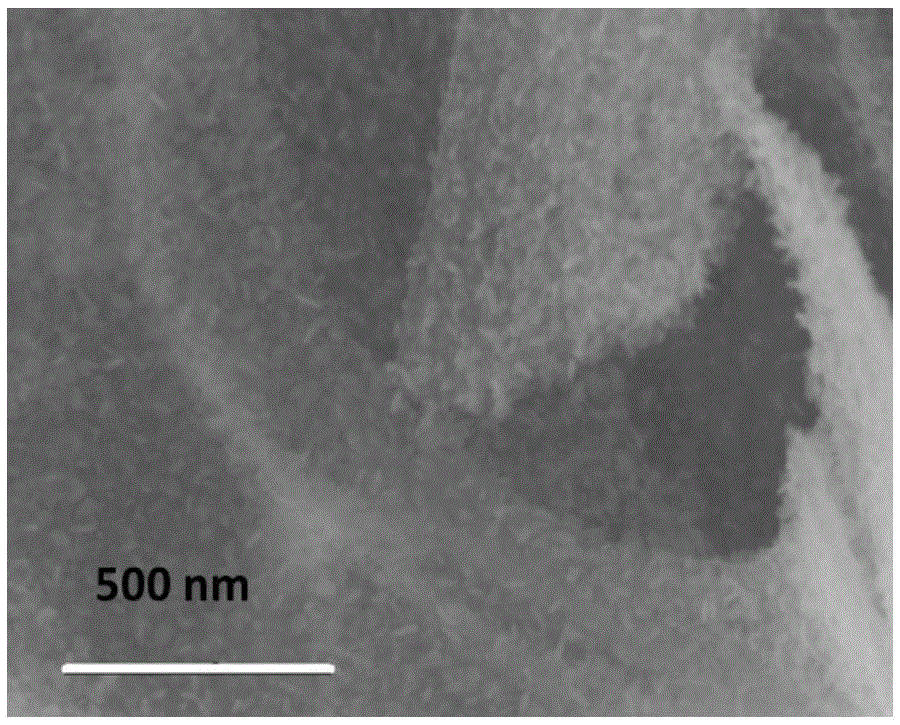

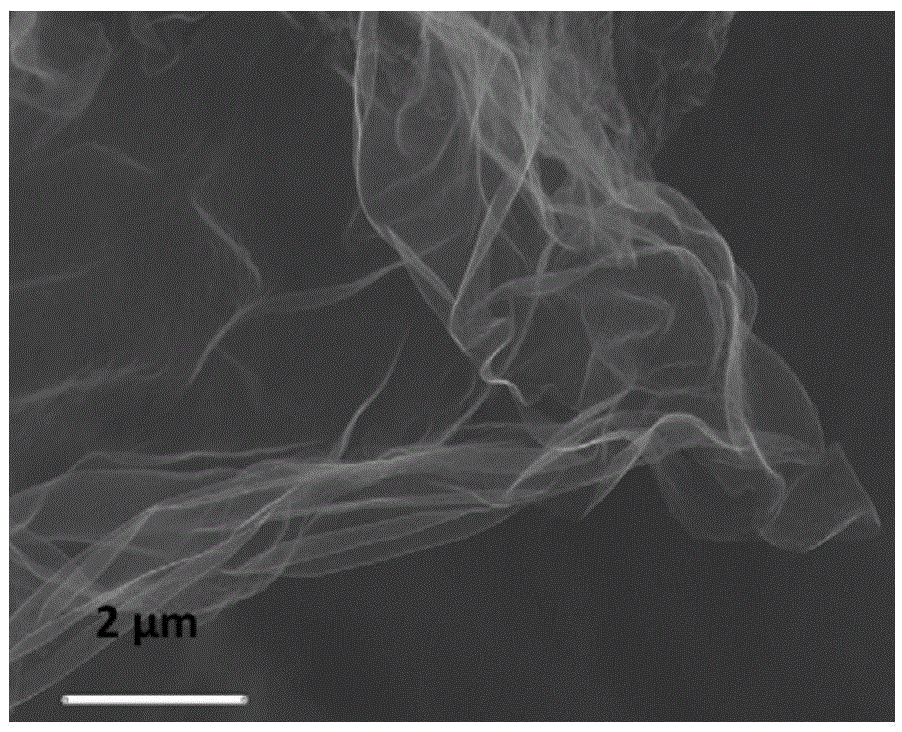

[0036] Dissolve zinc nitrate hexahydrate and glucose in an aqueous solution in a mass ratio of 4:1, and first react the mixed aqueous solution at 150°C in the air environment of a muffle furnace to form a zinc oxide / porous ultra-thin carbon layer / zinc oxide sandwich structure product, Scanning electron microscope picture as figure 1 shown;

[0037] Then, the ZnO / porous ultra-thin carbon layer / ZnO interlayer structure product is further graphitized in a tube furnace at a heating rate of 10°C / min and heated to 800°C for 5min in a non-oxidizing gas atmosphere. Wash away the zinc oxide with an aqueous acid solution.

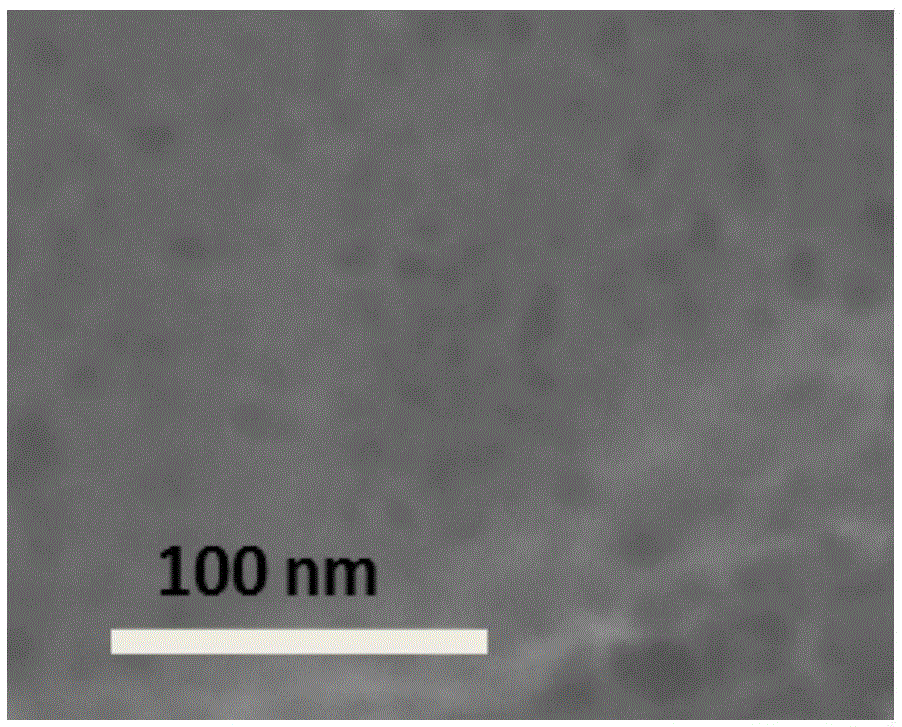

[0038] Analysis of the nitrogen-doped porous graphene data prepared in this example shows that the pore diameter ranges from 2 to...

Embodiment 2

[0040] This embodiment relates to a method for preparing nitrogen-doped porous graphene with a high specific surface area, which is economical, scalable and has a narrow pore size distribution. The method comprises the following steps:

[0041] Dissolve zinc nitrate hexahydrate and soluble starch in an aqueous solution at a mass ratio of 4:1, and first react the mixed aqueous solution at 150°C in the air environment of a muffle furnace to form a zinc oxide / porous ultra-thin carbon layer / zinc oxide sandwich structure product ;

[0042] Then the zinc oxide / porous ultra-thin carbon layer / zinc oxide sandwich structure product is further heated in a tube furnace at a heating rate of 30°C / min, and heated to 500°C for 120min in a non-oxidizing gas atmosphere. After further graphitization, Wash away the zinc oxide with an aqueous acid solution.

[0043] Analysis of the nitrogen-doped porous graphene data prepared in this example shows that the pore size range is 2-6 nm, and the pore ...

Embodiment 3

[0045] This embodiment relates to a method for preparing nitrogen-doped porous graphene with a high specific surface area, which is economical, scalable and has a narrow pore size distribution. The method comprises the following steps:

[0046] Zinc nitrate hexahydrate and sucrose are dissolved in an aqueous solution at a mass ratio of 4:1, and the mixed aqueous solution is first rapidly reacted at 500°C in a muffle furnace air environment to form a zinc oxide / porous ultra-thin carbon layer / zinc oxide sandwich structure product;

[0047] Then, the ZnO / porous ultra-thin carbon layer / ZnO sandwich structure product is further graphitized in a tube furnace at a heating rate of 2°C / min, heated to 1700°C for 5min in a non-oxidizing gas atmosphere, and then graphitized. Wash off the zinc oxide with an aqueous acid solution.

[0048] The data analysis of the nitrogen-doped porous graphene prepared in this example shows that the pore size ranges from 2 to 6 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com