Surface modification method for SnO<2>-based photo-anode

A surface modification, photoanode technology, applied in photovoltaic power generation, photosensitive equipment, capacitor electrodes, etc., can solve the problems of strong corrosion, expensive equipment, strong irritation of the upper respiratory tract mucosa, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

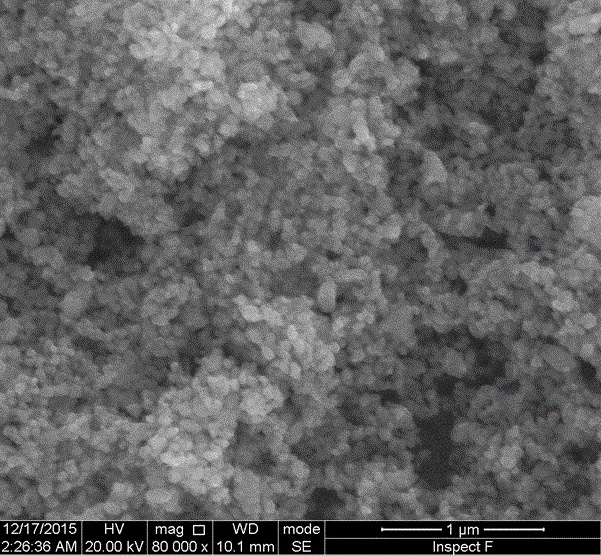

[0017] (1) SnO 2 The porous film is immersed in a mixed solution of concentrated ammonia water (25% by mass fraction) and aqueous hydrogen peroxide solution (30% by mass) with a volume ratio of 1:1. After 5 minutes, it is taken out and rinsed with deionized water to obtain a hydrophilic surface. treated SnO 2 porous film.

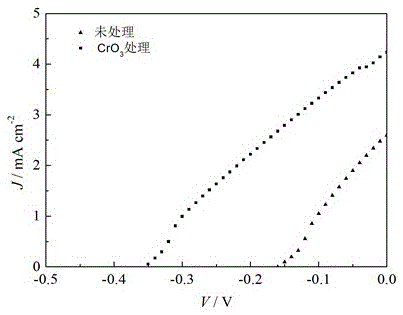

[0018] (2)CrO x Preparation of the modification layer

[0019] a) 1gCrO 3 Dissolve in 100ml secondary deionized water to obtain solution a; b) configure 0.2mol / L aqueous solution b of acetic acid; c) hydrophilize the SnO 2 Soak the porous film in solution a, take it out after a certain period of time and soak it in deionized water or rinse it with deionized water, then soak it in solution b for a period of time, take it out and soak it in deionized water or rinse it with deionized water; repeat step c) Three times, calcined at 550°C to obtain CrO x Surface modified SnO 2 Photoanode.

[0020] (3) CdS quantum dots were deposited on the photoanode by t...

Embodiment 2

[0022] (1) SnO 2 The porous film is immersed in a mixed solution of concentrated ammonia water (25% by mass fraction) and aqueous hydrogen peroxide solution (30% by mass) with a volume ratio of 1:1. After 5 minutes, it is taken out and rinsed with deionized water to obtain a hydrophilic surface. treated SnO 2 porous film.

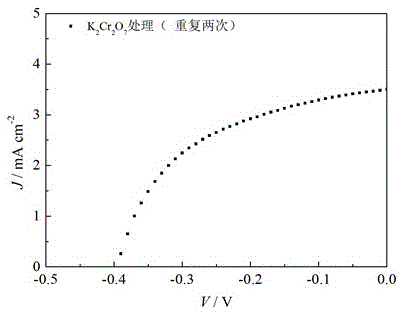

[0023] (2)CrO x Preparation of the modification layer

[0024] a) Add 2gNa 2 Cr 2 o 7 Dissolve in 100ml secondary deionized water to obtain solution a; b) configure 0.1mol / L HCl aqueous solution b; c) hydrophilize the SnO 2 Soak the porous film in solution a, take it out after a certain period of time and soak it in deionized water or rinse it with deionized water, then soak it in solution b for a period of time, take it out and soak it in deionized water or rinse it with deionized water; repeat step c) Twice, calcined at 500°C for 30min to obtain CrO x Surface modified SnO 2 Photoanode.

[0025] (3) CdS quantum dots were deposited on the photoano...

Embodiment 3

[0027] (1) SnO 2 The porous film is immersed in a mixed solution of concentrated ammonia water (25% by mass fraction) and aqueous hydrogen peroxide solution (30% by mass) with a volume ratio of 1:1. After 5 minutes, it is taken out and rinsed with deionized water to obtain a hydrophilic surface. treated SnO 2 porous film.

[0028] (2)CrO x Preparation of the modification layer

[0029] a) Add 4gK 2 Cr 2 o 7 Dissolve in 100ml secondary deionized water to obtain solution a; b) configure 0.2mol / L HCl aqueous solution b; c) hydrophilize the SnO 2 Soak the porous film in solution a, take it out after 2 minutes and soak it in deionized water or rinse it with deionized water, then soak it in solution b for a period of time, take it out and soak it in deionized water or rinse it with deionized water; repeat step c) 4 times, calcined at 500°C for 30min to obtain CrO x Surface modified SnO 2 Photoanode.

[0030] (3) CdS quantum dots were deposited on the photoanode by the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com