Energy-saving gas cooking stove

A cooking stove and gas technology, which is applied to household stoves, heating fuels, household stoves/stoves, etc., can solve problems such as low thermal efficiency, achieve the effects of reducing consumption, increasing furnace temperature, and improving kitchen environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

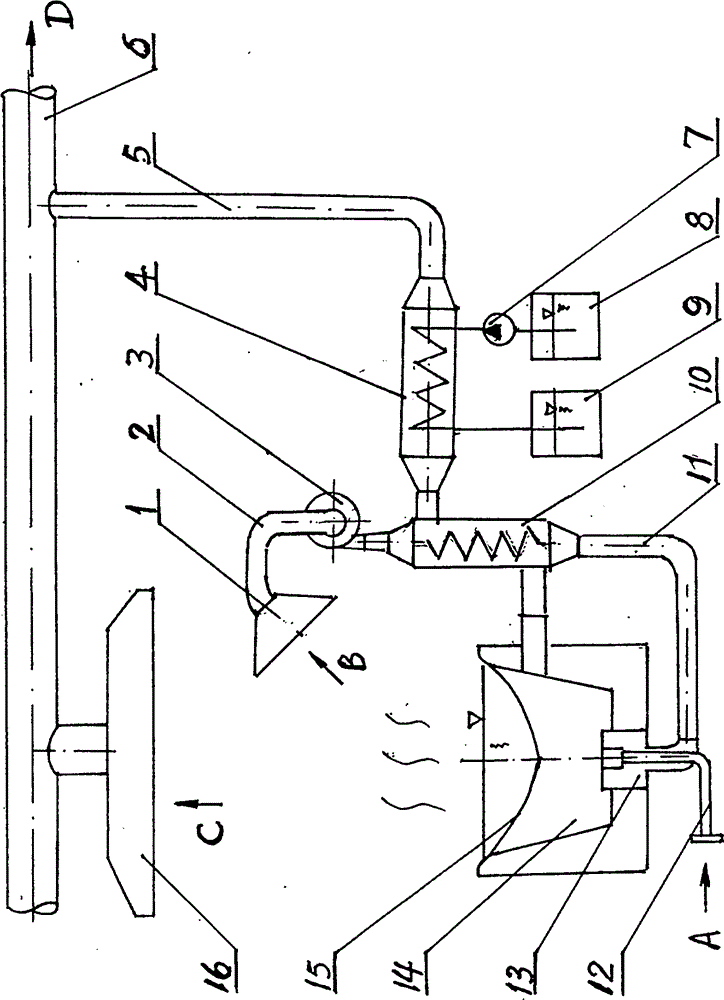

[0037] A gas-fired energy-saving cooker is composed of a small gas collecting hood (1), a small gas collecting hood connecting pipe (2), a centrifugal blower (3), a low-temperature hot water heater (4), a small chimney (5), and a total chimney (6 ), water pump (7), cold water tank (8), hot water tank (9), high temperature air preheater (10), high temperature air preheater connecting pipe (11), gas inlet pipe (12), stove burner ( 13), furnace (14), pot (15), large gas collecting hood (16) form. Pot (15) produces a large amount of oil fume and water vapor in cooking process, forms oil fume mixture with surrounding air. These fume mixtures are collected by the A port of the small gas collection hood (1), and are connected with the suction port of the centrifugal blower (3) through the small gas collection hood connecting pipe (2) to implement the collection and delivery of the oil fume mixture.

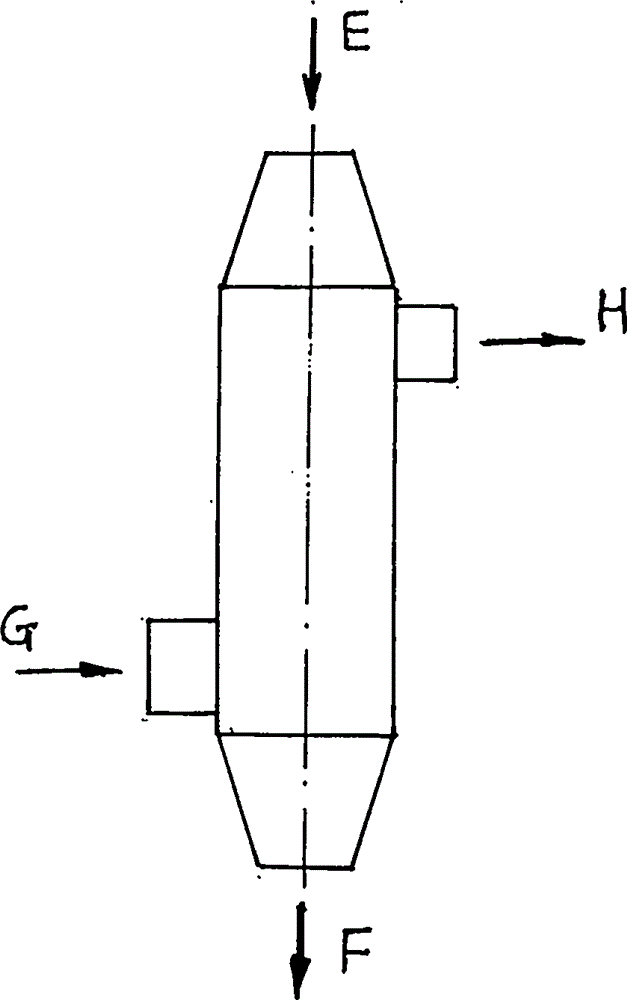

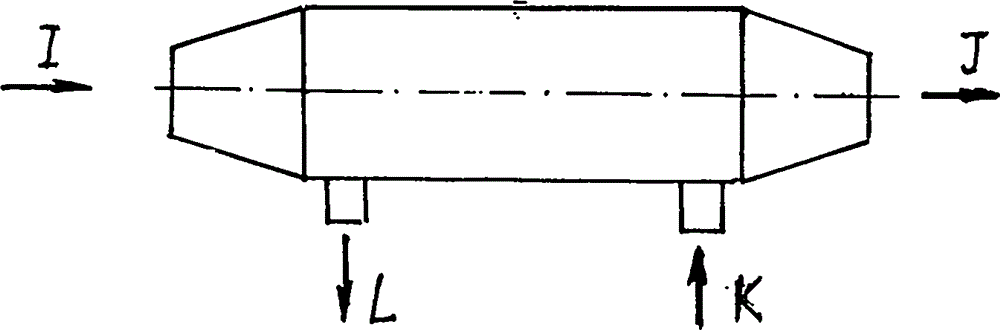

[0038] The high-temperature air preheater (10) is a rectangular shell-and-tube heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com