A three-node pipe collar type j-laying system

A three-node, tower-laying technology, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of unsynchronized processes, high riser installation costs, and low laying efficiency to achieve transmission Ease of operation, weight reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

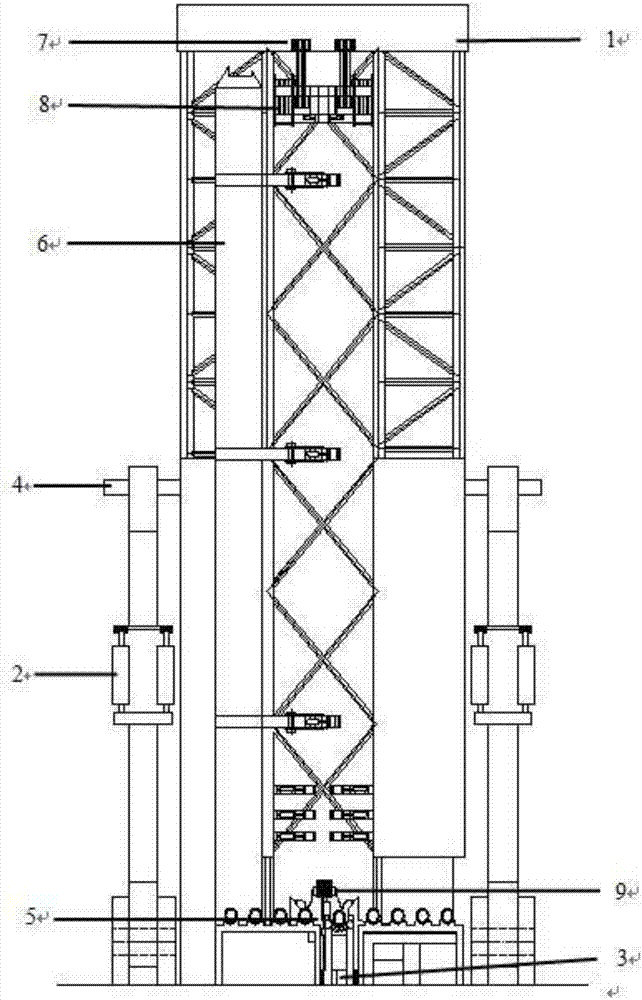

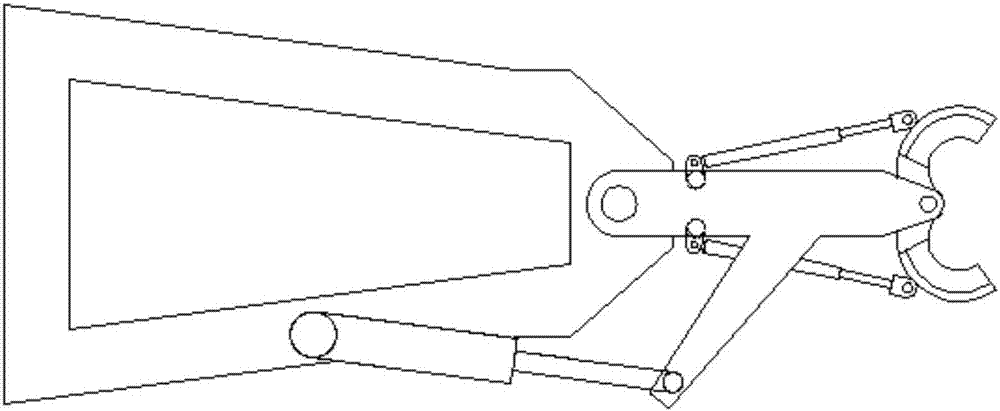

[0025] combine Figure 1~4 , the object of the present invention is to address the problems existing in the laying process of the existing J-type pipe-laying vessel, comprehensively consider the laying efficiency and operability of the J-type laying system, and design a new type of deep-water J-laying system by optimizing the J-type laying system. Type laying system, which can complete the laying of 3-node pipelines, and can realize a wide range of angle adjustment of the laying tower during the laying process, adapting to the laying of more pipelines at different water depths, and at the same time realize the installation of some key equipment, such as pipeline terminals (PLET, PLEM), etc., improve the feasibility of J-laying.

[0026] The present invention adopts the following technical proposals, which mainly include a pipe support device, an angle adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com