Lubricant additive with antioxidant, antiwear and rustproof functions as well as preparation method and application thereof

A lubricating oil additive and functional technology is applied in the field of lubricating oil additive with anti-oxidation, anti-wear and anti-rust functions and its preparation field. The effect of improving practicality and excellent anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

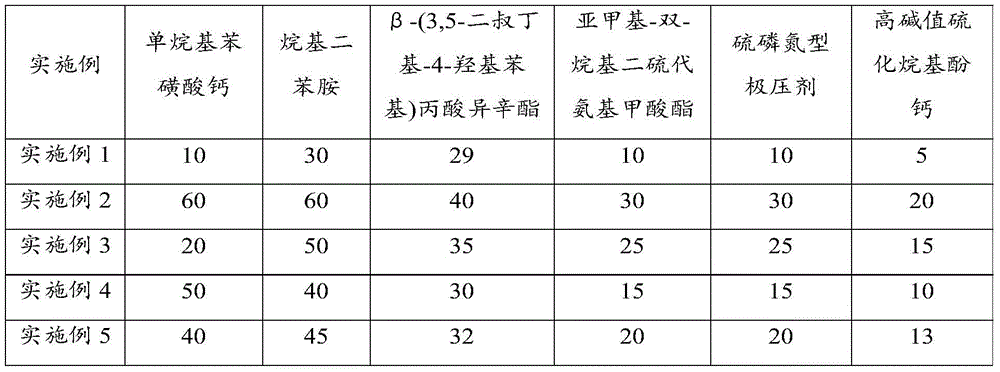

[0029] The raw material ratio of the lubricating oil additives with anti-oxidation, anti-wear and anti-rust functions of each embodiment is shown in Table 1 below. The preparation method is as follows: stir and mix all raw materials in a container under normal pressure and 45-80 ° C. Yes, wherein, the base number of calcium monoalkylbenzenesulfonate is controlled at 0-6mgKOH / g, and the carbon number of the side chain alkyl group is between 18-30. After testing the base number of the lubricating oil additives in various embodiments of the present invention ≥50mgKOH / g, calcium content ≥1.2wt%, sulfur content ≥0.85wt%, phosphorus content ≥0.5wt%, nitrogen content ≥1.8wt%;

[0030] The raw material addition amount (unit: kg) of each embodiment of table 1

[0031]

Embodiment 6

[0033] The amount of raw materials added and the selection of types are basically the same as in Example 5 of the present invention, except that the alkylbenzene sulfonate is a mixture of calcium monoalkylbenzenesulfonate and barium monoalkylbenzenesulfonate, and there is no definite amount between the two Limit, and during the preparation process, the mixing and stirring rate is controlled at 100 rad / min, the stirring time is controlled at more than 30 min, and the stirring temperature is controlled at 80°C.

Embodiment 7

[0035] Raw material addition amount and type selection are basically consistent with embodiment 5 of the present invention, only the carbon number of the alkyl group of high alkali value sulfurized alkylphenate calcium is controlled between 12-15, and in the preparation process, the speed control of mixing and stirring At 200rad / min, the stirring time was controlled at 50min, and the stirring temperature was controlled at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com