Method for producing organic high nitrogen fertilizer using agricultural solid waste and fertilizer products produced thereby

A solid waste and high-nitrogen fertilizer technology is applied in the direction of organic fertilizers, preparation of organic fertilizers, and treatment of bio-organic parts. It can solve problems such as neglected ratios, low fertilizer efficiency, and organic fertilizer restrictions, and achieve improved conversion rates and low raw material costs. , the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

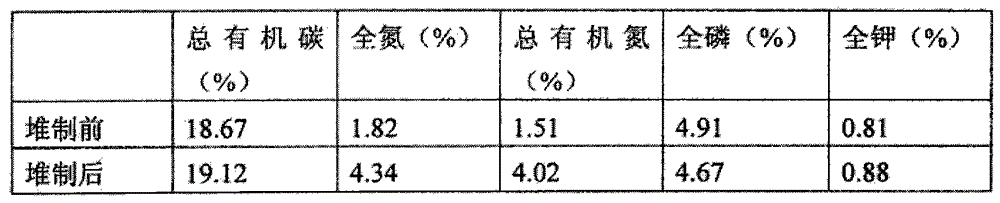

[0014] Pig manure (without dehydration), rice straw (crushed to about 20 cm), ammonium chloride and bean dregs were mixed at a ratio of 75:12:3:10 (all based on the dry weight of these four compost materials) and then fermented. Keep it up to 60-70°C for 4 days, then turn the compost once every 2 days, and add 2% (based on the dry weight of the compost at this time) of ammonium chloride evenly each time until the compost temperature starts from 50-60°C Cool down and compost for another 5 days to further post-ripen and make a real organic fertilizer product. The entire composting time is 24 days, and its nutrient content is shown in Table 1.

[0015] Table 1 Total organic carbon of nutrients in pig manure fertilizer before and after composting

[0016]

[0017] Table 1 shows that technology of the present invention and production process can produce the high-grade organic fertilizer that total organic nitrogen content surpasses 4% and total nutrient (nitrogen, phosphorus, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com