Sludge pyrolysis carbonization technique and device

A process method and carbonization treatment technology, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., and can solve the problems of high investment and operation costs of sludge treatment and disposal, and environmental protection fields Difficulty, secondary pollution and other problems, to achieve the effect of no secondary pollution, stable output state, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

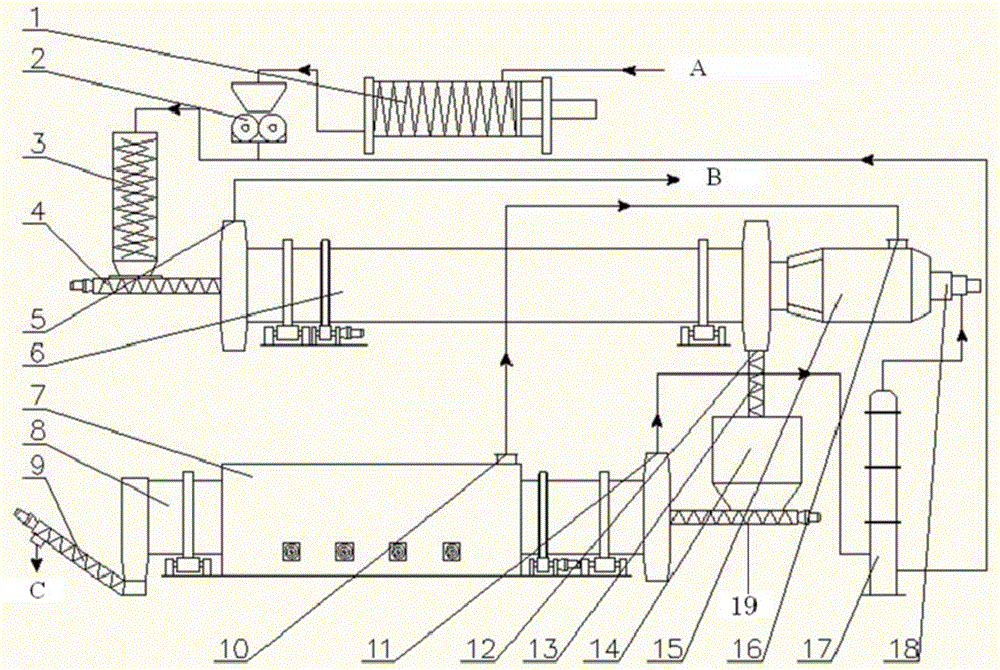

[0069] The model of the extruder used in this example is WGL-11, the model of the pulverizer is LSF30-2, the model of the mixing mixer is LSB600, the model of the screw feeder is LSJ28-2.5, and the model of the internal heating rotary kiln dryer is It is LSG1200-12, the model of heating furnace is LSL6, the model of external heating pyrolysis carbonization furnace is LSR800-10, the model of screw conveyor I is LSJ28-3, the model of screw conveyor II is LSJ30-3, and the model of storage bin is LSC1 , The model of the hot blast stove is LSR12000, the model of the separation and purification tower is LST500-3, the model of the burner is STAR-500, and the model of the screw conveyor III is LSJ30-3.

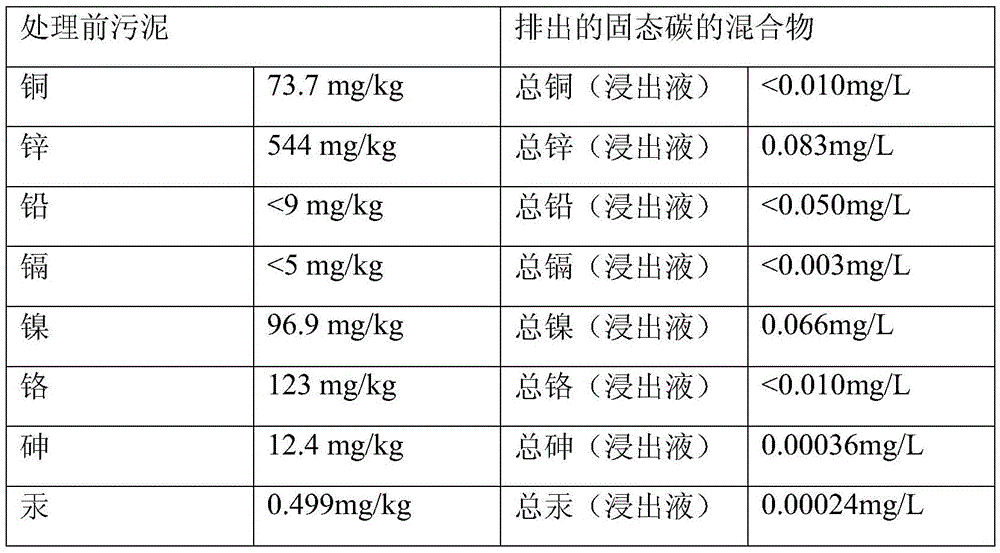

[0070] The treated sludge is the sludge formed after the sewage treatment plant of Shunyi New City Ecological Water Transfer Center and Shunyi District Jinma Development Zone Sewage Treatment Plant. The moisture content of the sludge is 85-90%, and the toxic heavy metals copper, zinc, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com