Method for macroscopic preparation of Fe3O4 nanorods

A nanorod, fe3o4caso4 technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low product purity and difficulty in large-scale production, and achieve simple process, easy control of conditions, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

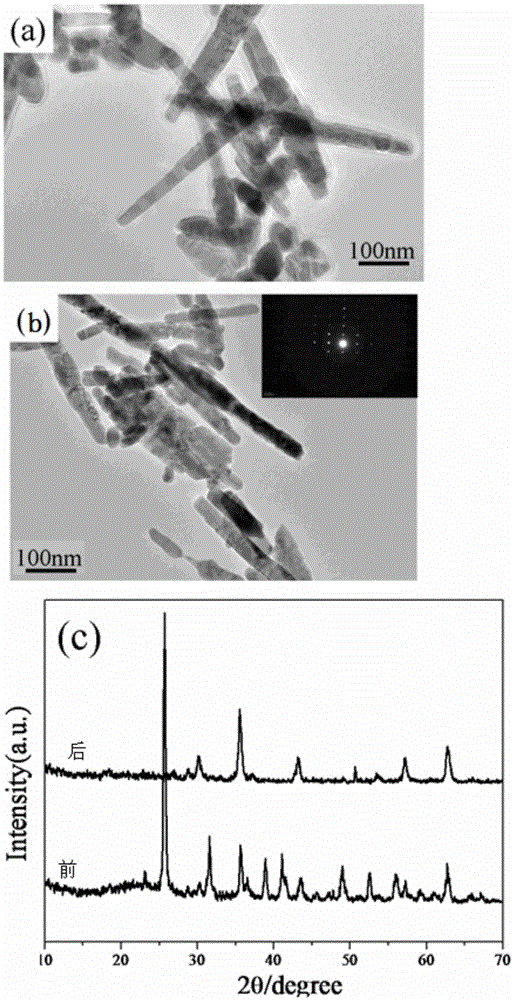

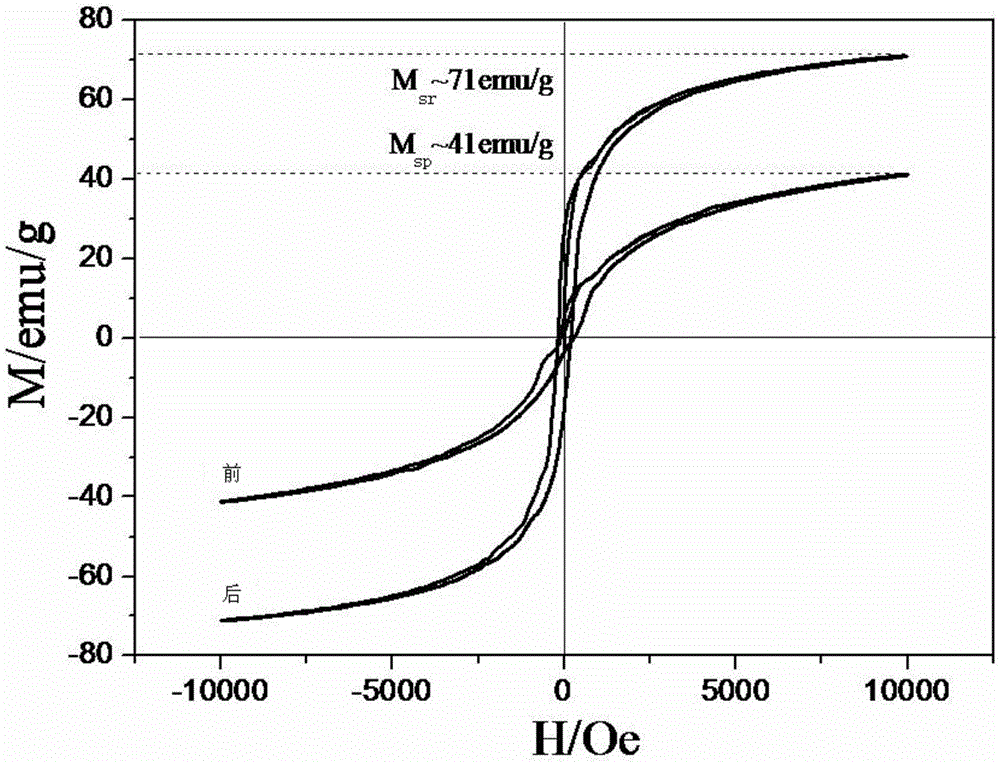

[0024] Example 1 (Fe 2 SO 4 ·7H 2 O and CaSO 4 2H 2 O weight ratio is 2:1)

[0025] Step 1, Preparation of α-FeOOH / CaSO 4 2H 2 O precursor

[0026] (1) Add 2g of Fe 2 SO 4 ·7H 2 O was dissolved in 100 mL of distilled water, and magnetically stirred for 2 minutes at room temperature to fully dissolve it to obtain solution a.

[0027] (2) Add 1g of CaSO 4 2H 2 O solution was slowly added to solution a, and magnetic stirring was continued for 3 minutes to obtain brownish red suspension b.

[0028] (3) A small amount of ammonia water was added dropwise to adjust the pH value of the suspension b to 10 to obtain a dark brown solution c.

[0029] (4) Filter solution c, and then dry it in an oven at 100°C for 2 hours to obtain α-FeOOH / CaSO 4 2H 2 O precursor.

[0030] Step 2, preparation of Fe by solid phase reduction reaction 3 o 4 CaSO 4 , post-processing to get Fe 3 o 4 Nano stave

[0031] (1) A certain amount of α-FeOOH / CaSO 4 2H 2 The O precursor was put i...

Embodiment 2

[0037] Example 2 (Fe 2 SO 4 ·7H 2 O and CaSO 4 2H 2 O weight ratio is 1:1)

[0038] Step 1, Preparation of α-FeOOH / CaSO 4 2H 2 O precursor

[0039] (1) Add 2g of Fe 2 SO 4 ·7H 2 O was dissolved in 100 mL of distilled water, and magnetically stirred for 3 minutes at room temperature to fully dissolve it to obtain solution a.

[0040] (2) Add 2g of CaSO 4 2H 2 O solution was slowly added to solution a, and magnetic stirring was continued for 2 minutes to obtain brownish red suspension b.

[0041] (3) A small amount of ammonia water was added dropwise to adjust the pH value of the suspension b to 7 to obtain a dark brown solution c.

[0042] (4) Filter solution c, and then dry in an oven at 60°C for 6 hours to obtain α-FeOOH / CaSO 4 2H 2 O precursor.

[0043] Step 2, preparation of Fe by solid phase reduction reaction 3 o 4 CaSO 4 , post-processing to get Fe 3 o 4 Nano stave

[0044] (1) A certain amount of α-FeOOH / CaSO 4 2H 2 The O precursor was put into a...

Embodiment 3

[0047] Embodiment 3 (Fe 2 SO 4 ·7H 2 O and CaSO 4 2H 2 O weight ratio is 1:2)

[0048] Step 1, Preparation of α-FeOOH / CaSO 4 2H 2 O precursor

[0049] (1) Add 1g of Fe 2 SO 4 ·7H 2 O was dissolved in 100 mL of distilled water, and magnetically stirred at room temperature for 1 minute to fully dissolve to obtain solution a.

[0050] (2) Add 2g of CaSO 4 2H 2 O solution was slowly added to solution a, and magnetic stirring was continued for 3 minutes to obtain brownish red suspension b.

[0051] (3) A small amount of ammonia water was added dropwise to adjust the pH value of the suspension b to 12 to obtain a dark brown solution c.

[0052] (4) Filter solution c, and then dry it in an oven at 80°C for 6 hours to obtain α-FeOOH / CaSO 4 2H 2 O precursor.

[0053] Step 2, preparation of Fe by solid phase reduction reaction 3 o 4 CaSO 4 , post-processing to get Fe 3 o 4 Nano stave

[0054] (1) A certain amount of α-FeOOH / CaSO 4 2H 2 The O precursor was put int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com