Method for preparing high aspect ratio silicon microstructure on basis of deep reactive ion etching technology

A deep reaction ion, high aspect ratio technology, applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of low roughness and difficulty in maintaining verticality, and achieve high instantaneous power and low The roughness of the side wall meets the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

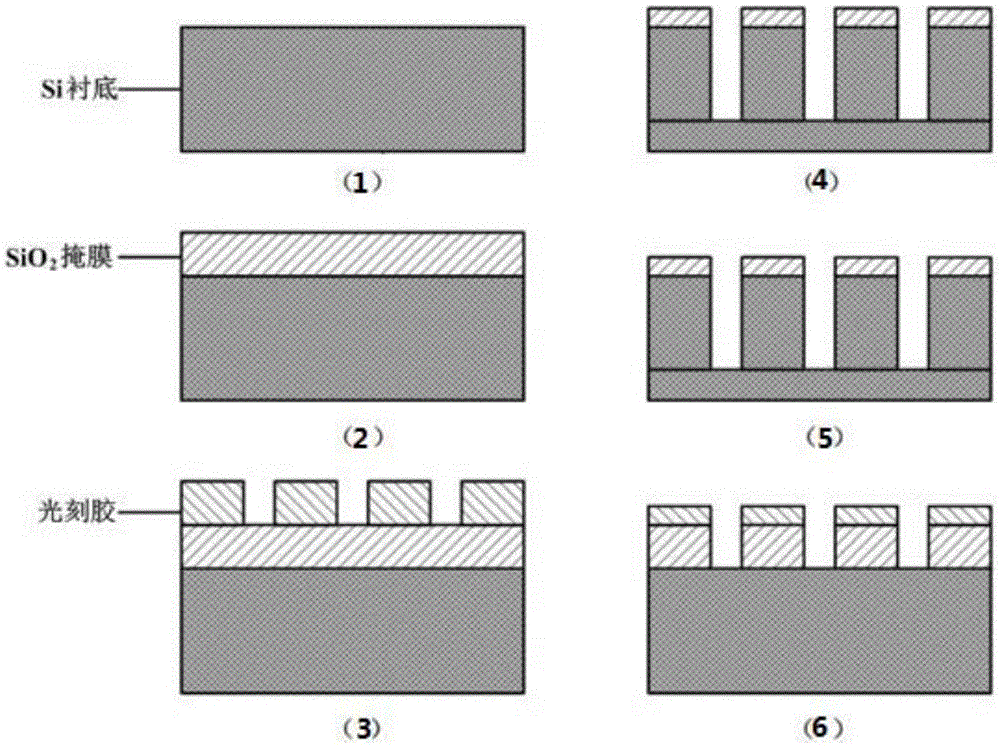

[0030] Embodiment: A method for preparing a high aspect ratio silicon microstructure based on deep reactive ion etching technology, comprising the following steps:

[0031] (1) cleaning a piece of n-type, (100) single crystal silicon as the substrate;

[0032] (2) Deposit a layer of SiO with a certain thickness on the surface of the silicon substrate 2 membrane;

[0033] (3) on SiO 2 The surface of the film is spin-coated with a certain thickness of photoresist, and the pattern transfer is realized through the photolithography process;

[0034] (4) Using reactive ion etching (RIE) etching technology, by adjusting CHF 3 and CF 4 Gas flow and etching power, the photoresist pattern is accurately copied to SiO 2 film, making SiO 2 The verticality of the membrane side wall can reach about 85 degrees;

[0035] (5) Use DRIE process to etch to form a three-dimensional deep groove structure with high aspect ratio: select a certain flow rate of SF 6 As the etching gas, select a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com