Low-noise rotor-stator fan system

A fan system, low-noise technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as adverse effects of the driver's working environment, and achieve a weakened span Relevance, improving work comfort, and reducing the effect of rotational-static interference noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

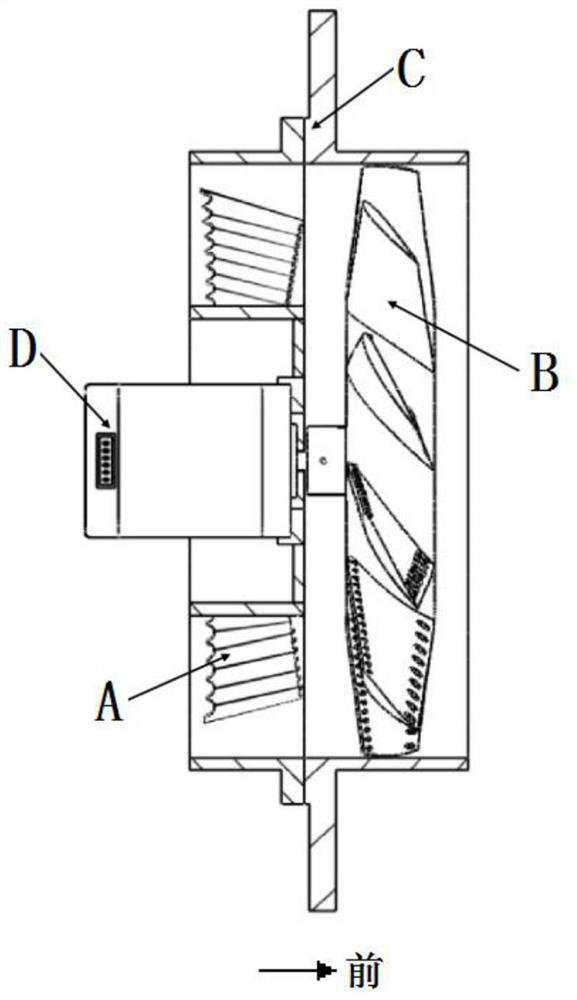

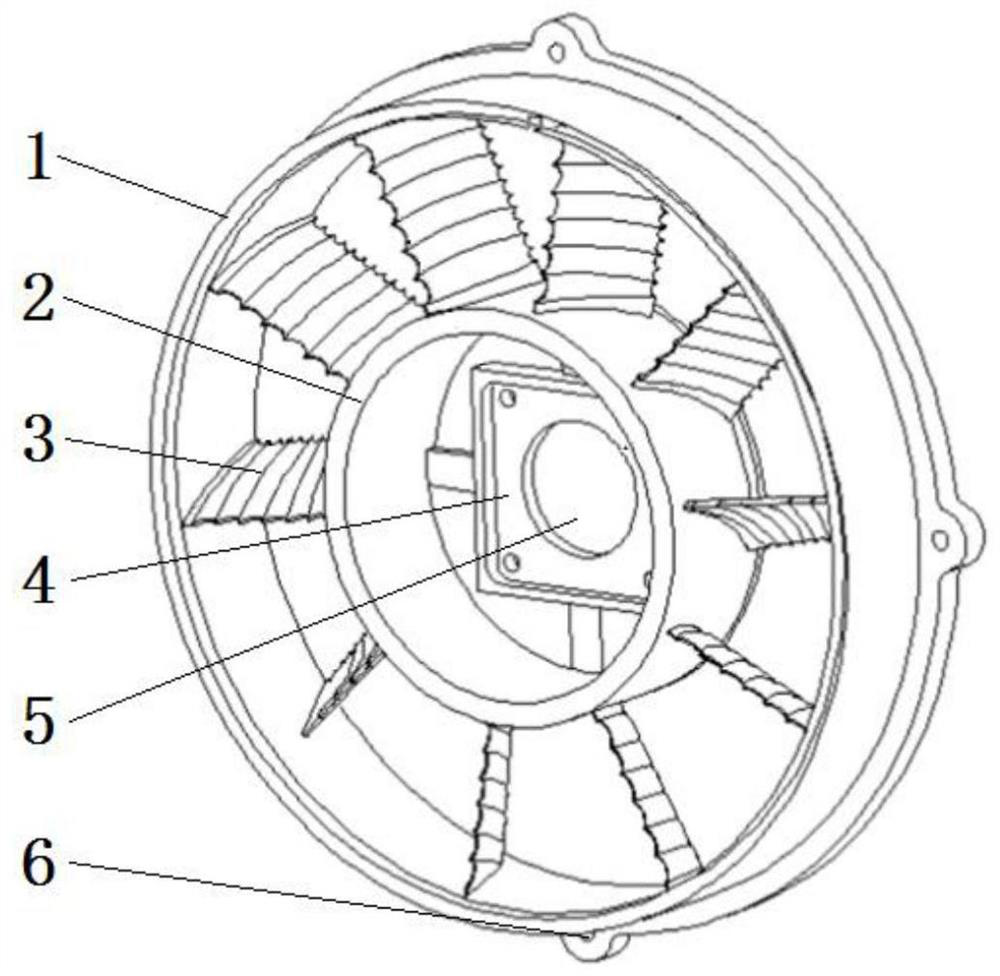

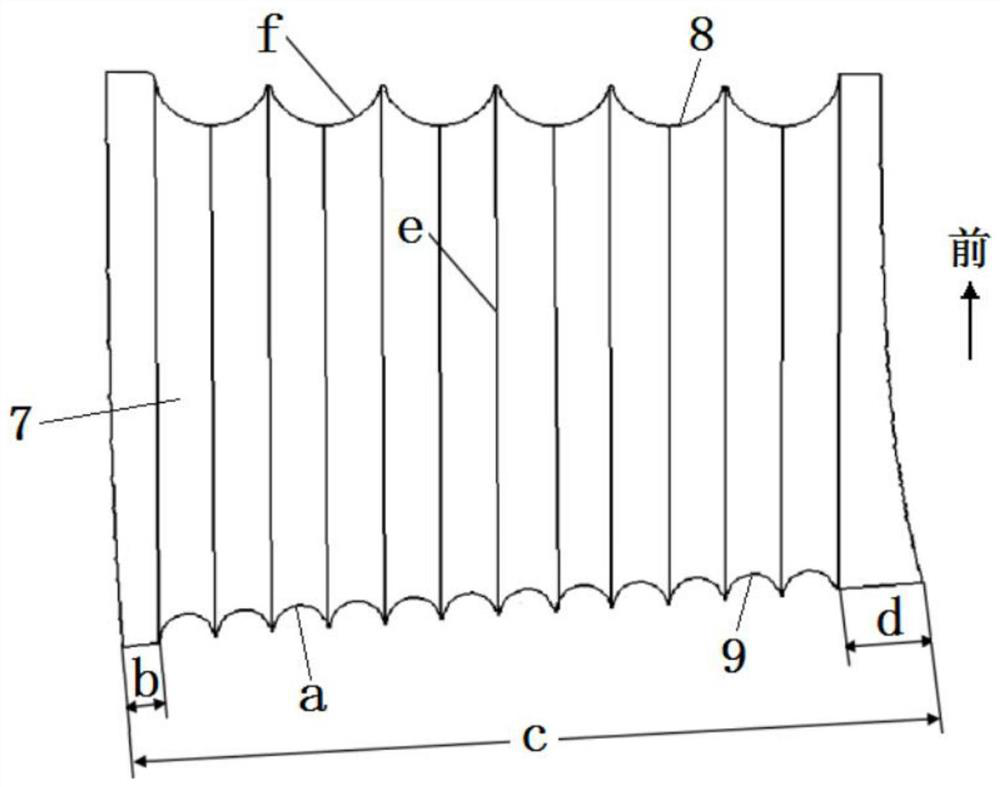

[0032] Put the stator fan assembly A with the leading edge wave 8 and the trailing edge wave 9, the rotor fan assembly B with the bionic spoiler structure 15 and the inner sawtooth structure 17, the bracket C, and the motor D according to figure 1 Mounting shown is fixed. The sawtooth structure is determined by the wave sawtooth a, where the chord length of the middle section of the blade is e = 38mm, that is, the wave sawtooth a = 1.9mm, b = 2.6mm, the total length of the blade c = 57mm, the leftover d = 7.8mm, the leading edge of the blade Wave sawtooth f=8mm. The stator fan blade group 3 is composed of 8--10 stator fan blades, the base 4 is fixedly connected to the inner ring of the inner ring 2, and the 8--10 stator fan blades 7 of the stator fan blade group 3 are evenly distributed along the circumference, and Fixedly connected between the outer ring 1 and the inner ring 2, the included angle α1 between the centerline of 8--10 stator fan blades 7 of the stator fan blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com