Production method of black tea containing eurotium cristatum

A production method, the technology of Fu grain tea, applied in tea treatment before extraction, etc., can solve the problem of low golden flower coverage, and achieve the effect of good fluffiness, dense golden flower, and moderate density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

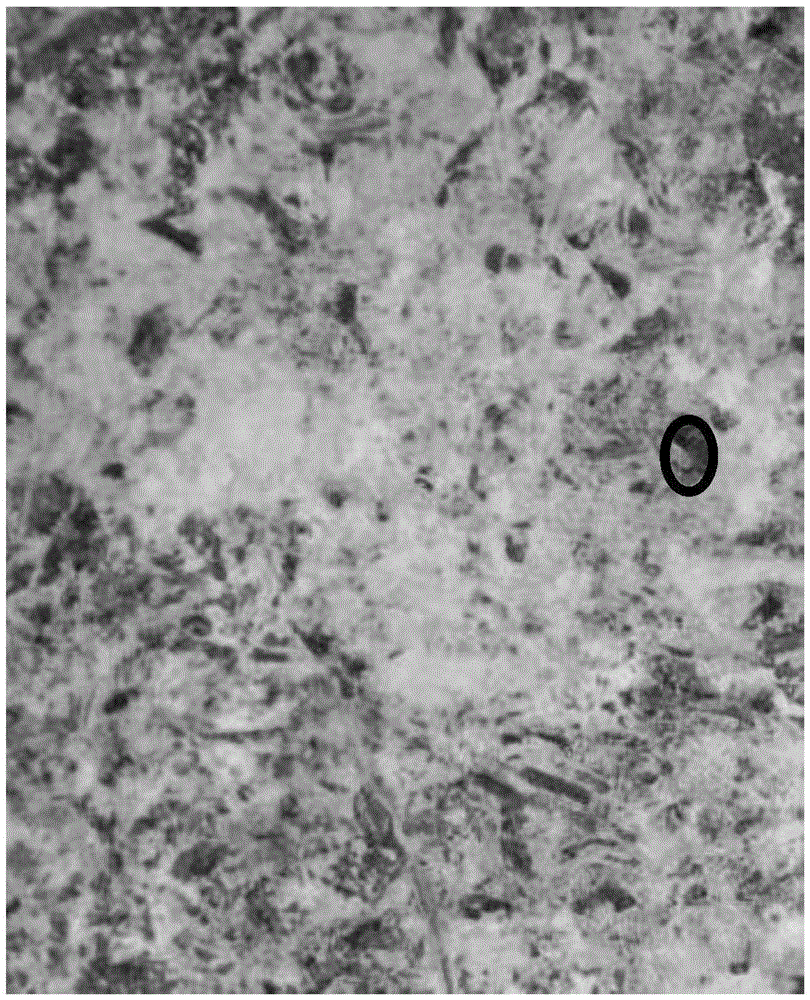

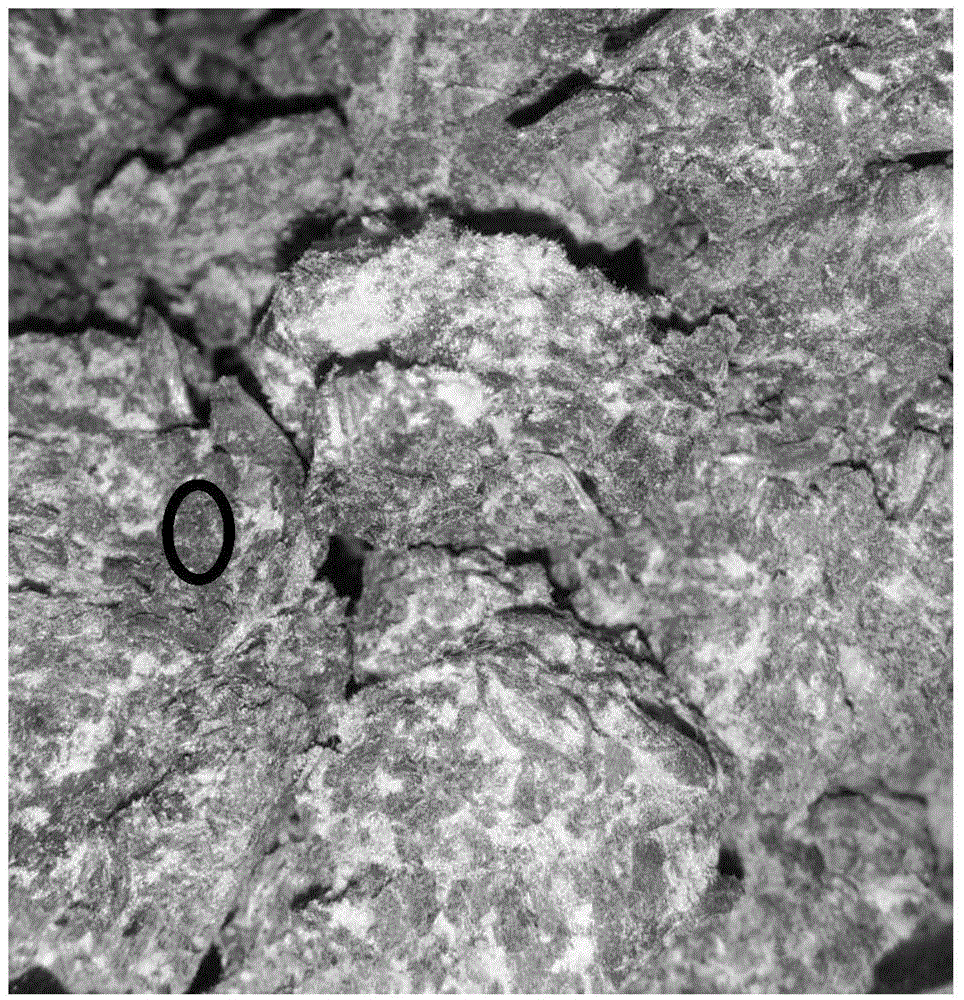

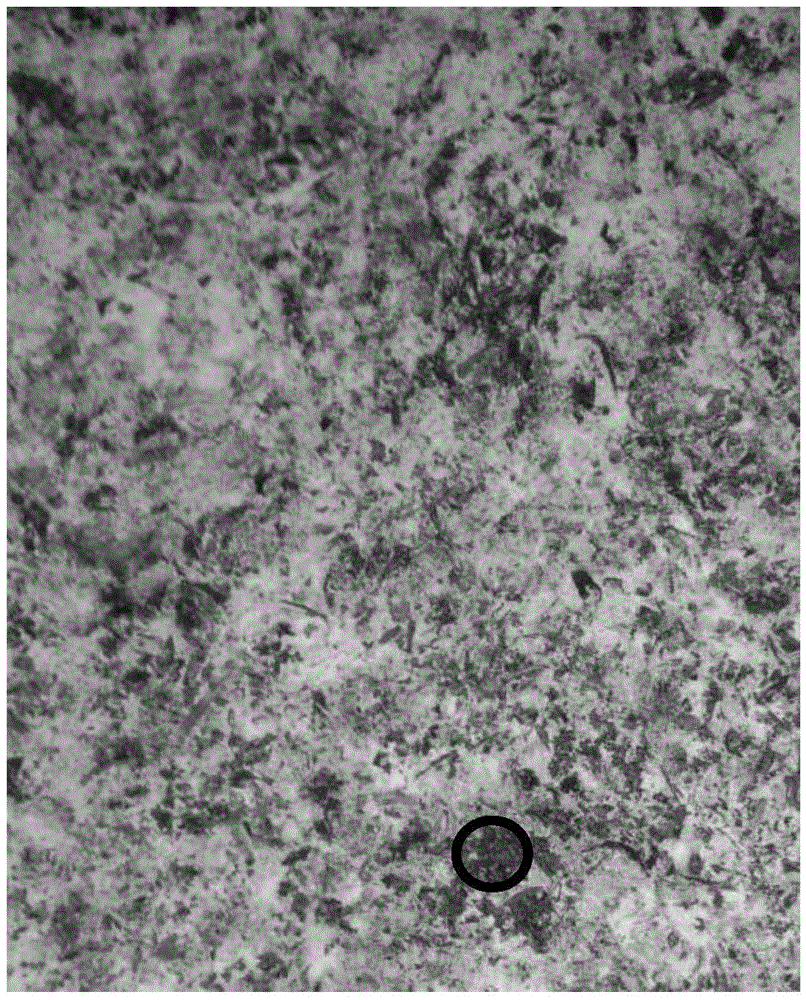

Image

Examples

Embodiment 1

[0035] A kind of production method of Fu grain tea of present embodiment 1, comprises the following steps:

[0036] Step 1. Using a double-roller granulator to granulate the tea raw material after the heaping treatment, and obtain tea granules after drying. Then the tea granules are pretreated to obtain tea granules with a water content of 10%-20%. Wherein, before granulation, the tea raw material is subjected to steam heating and steaming treatment. Specifically, the raw tea leaves are steamed at a steam temperature of 100° C. for 2-6 minutes before granulation. Increase the cohesion between tea leaves, making it easy to shape.

[0037] In the first step, the tea granule raw material is obtained by extruding with a double-roll granulator, and the tea granule raw material is pretreated before compression molding to improve the softness and formability of the tea granule raw material. Specifically, the pretreatment is: steaming and softening the raw material of tea granule...

Embodiment 2

[0044] A kind of production method of Fu grain tea of present embodiment 2, comprises the following steps:

[0045] Step 1. Using a double-roller granulator to granulate the tea raw material after the heaping treatment, and obtain tea granules after drying. Then the tea granules are pretreated to obtain tea granules with a water content of 14%-16%. Wherein, before granulation, the tea raw material is subjected to steam heating and steaming treatment. Specifically, the raw tea leaves are steamed at a steam temperature of 100° C. for 4-5 minutes before granulation. Increase the cohesion between tea leaves, making it easy to shape.

[0046] In the first step, the tea granule raw material is obtained by extruding with a double-roll granulator, and the tea granule raw material is pretreated before compression molding to improve the softness and formability of the tea granule raw material. Specifically, the pretreatment is: steaming and softening the raw material of tea granule...

Embodiment 3

[0053] A kind of production method of Fu grain tea of present embodiment 3, comprises the following steps:

[0054] Step 1. Using a double-roller granulator to granulate the tea raw material after the heaping treatment, and obtain tea granules after drying. Then the tea granules are pretreated to obtain tea granules with a water content of 14%-16%. Wherein, before granulation, the tea raw material is subjected to steam heating and steaming treatment. Specifically, the raw tea leaves are steamed at a steam temperature of 100° C. for 4-5 minutes before granulation. Increase the cohesion between tea leaves, making it easy to shape.

[0055] In the first step, the tea granule raw material is obtained by extruding with a double-roll granulator, and the tea granule raw material is pretreated before compression molding to improve the softness and formability of the tea granule raw material. Specifically, the pretreatment is: steaming and softening the raw material of tea granule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com