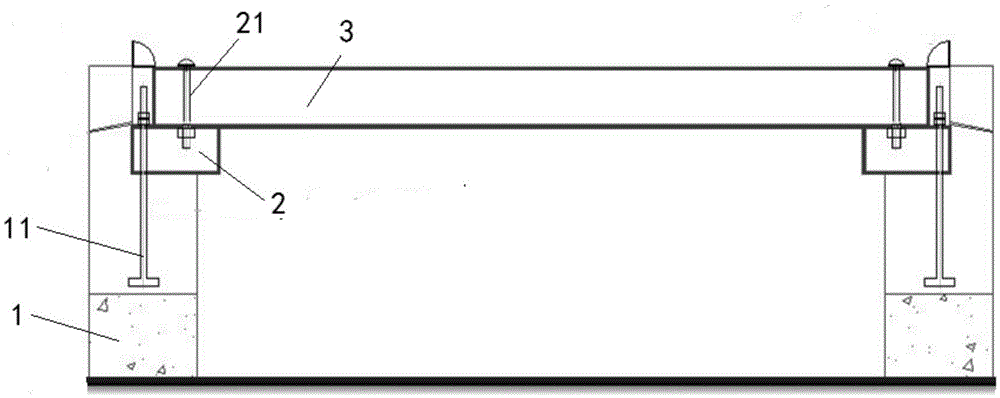

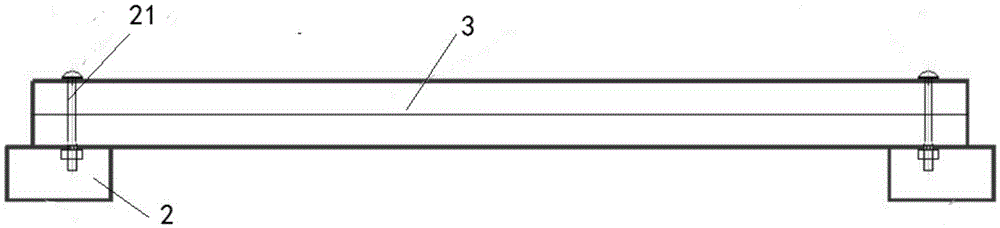

Cable working well lid

A technology for cable wells and cable workers, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of increasing the inspection workload of power cables, inability to directly check the conditions in the trench, and tedious maintenance work, etc. The effect of maintenance and overhaul efficiency, enhanced visibility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, the percentage by weight of each component in the epoxy primer is 26% of epoxy resin, 10% of epoxy resin insulation paint, 11% of ether ester solvent, 9% of ketone solvent, 20% of ester solvent, alcohol Ether solvent 8%, glycidyl ether diluent 16%. The glycidyl ether diluent is polyethylene glycol diglycidyl ether. The ether ester solvent is propylene glycol methyl ether acetate, the ketone solvent is acetone, the ester solvent is methyl acetate, and the alcohol ether solvent is ethylene glycol monomethyl ether.

Embodiment 2

[0024] Embodiment 2, the percentage by weight of each component in the epoxy primer is 25% of epoxy resin, 15% of epoxy resin insulation paint, 15% of ether ester solvent, 6% of ketone solvent, 15% of ester solvent, alcohol Ether solvent 10%, glycidyl ether diluent 14%. The glycidyl ether diluent is lauryl glycidyl ether. The ether ester solvent is epoxy ether propionate, the ketone solvent is methyl butanone, the ester solvent is ethyl acetate, and the alcohol ether solvent is ethylene glycol monoethyl ether.

Embodiment 3

[0025] Embodiment 3, the percentage by weight of each component in the epoxy primer is 30% of epoxy resin, 5% of epoxy resin insulation paint, 13% of ether ester solvent, 12% of ketone solvent, 25% of ester solvent, alcohol Ether solvent 5%, glycidyl ether diluent 10%. The glycidyl ether diluent is cresol glycidyl ether. The ether ester solvent is ethylene glycol butyl ether acetate, the ketone solvent is methyl isobutyl ketone, the ester solvent is propyl acetate, and the alcohol ether solvent is ethylene glycol monobutyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com