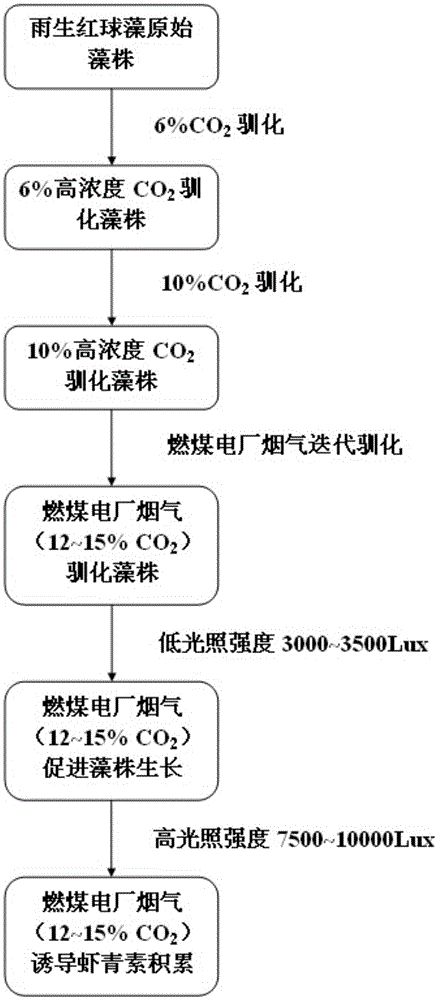

Method for promoting growth of Haematococcus pluvialis and accumulation of astaxanthin by flue gas CO2 domestication

A technology of Haematococcus pluvialis and CO2, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of growth inhibition of Haematococcus pluvialis, improve light energy utilization efficiency, and increase growth The effect of increasing the rate and expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Inoculate the Haematococcus pluvialis liquid into 400ml liquid BG-11 medium according to the inoculation amount of 10%, then place the inoculated medium into a 600ml cylindrical photosynthetic reactor, and then transfer it to the photosynthetic reactor High-concentration CO with a volume concentration of 6% 2 Gas, culture for 6 days under the conditions of a gas flow rate of 60ml / min, a light intensity of 3000 Lux and a temperature of 25°C; the above 6% CO 2 The cultured algae strains were transferred to a new liquid BG-11 medium with a 10% inoculum amount, and then a high-concentration CO with a volume concentration of 10% 2 For gas, culture for 6 days under the conditions of gas flow rate of 60ml / min, light intensity of 3000 Lux and temperature of 25℃;

[0035] (2) Take the above 10% CO 2 After 6 days of culture in air, the algae liquid was transferred to a new liquid BG-11 medium at 10% of the inoculum amount, and then the inoculated medium was placed in a cylindrical...

Embodiment 2

[0040] (1) Inoculate the Haematococcus pluvialis liquid into 400ml of liquid BG-11 medium according to the inoculation amount 15%, then place the inoculated medium in a cylindrical photosynthetic reactor with a volume of 600ml, and then transfer it to the photosynthetic reactor High-concentration CO with a volume concentration of 6% 2 Gas, cultured for 5 days under the conditions of a gas flow rate of 60ml / min, a light intensity of 3200 Lux and a temperature of 26℃; the above 6% CO 2 The cultivated algae strains were transferred to a new liquid BG-11 medium with 15% inoculum, and then a high concentration of CO with a volume concentration of 10% 2 Gas, culture for 5 days under the conditions of gas flow rate of 60ml / min, light intensity of 3200 Lux and temperature of 26℃;

[0041] (2) Take the above 10% CO 2 After 5 days of culture in air, the algae liquid was transferred to a new liquid BG-11 medium at 15% of the inoculum amount, and then the inoculated medium was placed in a 600m...

Embodiment 3

[0046] (1) Inoculate the Haematococcus pluvialis liquid into 400ml liquid BG-11 medium according to the inoculation amount 20%, then place the inoculated medium into a cylindrical photosynthetic reactor with a volume of 600ml, and then transfer it to the photosynthetic reactor High-concentration CO with a volume concentration of 6% 2 The gas, the gas flow is 60ml / min, the light intensity is 3500 Lux, and the temperature is 28°C for 4 days; the above 6% CO 2 The cultured algae strains were transferred to a new liquid BG-11 medium with 20% inoculum, and then a high concentration of CO with a volume concentration of 10% 2 For gas, culture for 4 days under the conditions of gas flow rate of 60ml / min, light intensity of 3500 Lux and temperature of 28℃;

[0047] (2) Take the above 10% CO 2 After 4 days of culture in air, the algae liquid was transferred to a new liquid BG-11 medium with 20% of the inoculum, and then the inoculated medium was placed in a 600ml cylindrical photosynthetic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com