A heavy oil coking equipment

A technology for coking equipment and heavy oil, which is applied in the multi-stage series-connected refining and cracking process treatment, etc., can solve the problem of not being able to improve the coking performance of heating furnace tubes at the same time, and achieves reduction of processing steps and processing difficulty, and easy fluidization. The effect of conveying and preventing combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0049] Examples 1-3 are used to illustrate the heavy oil coking method using the heavy oil coking equipment provided by the present invention.

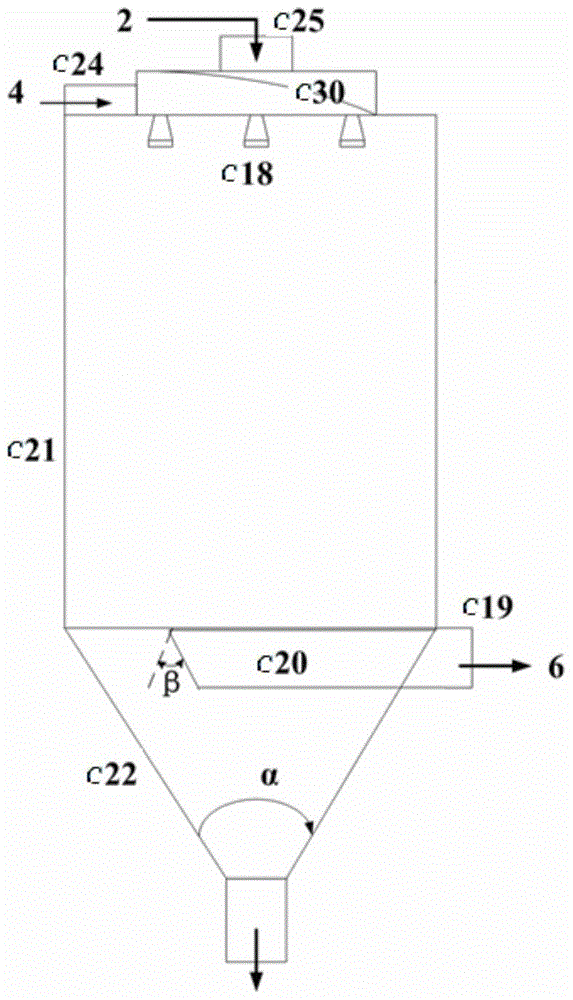

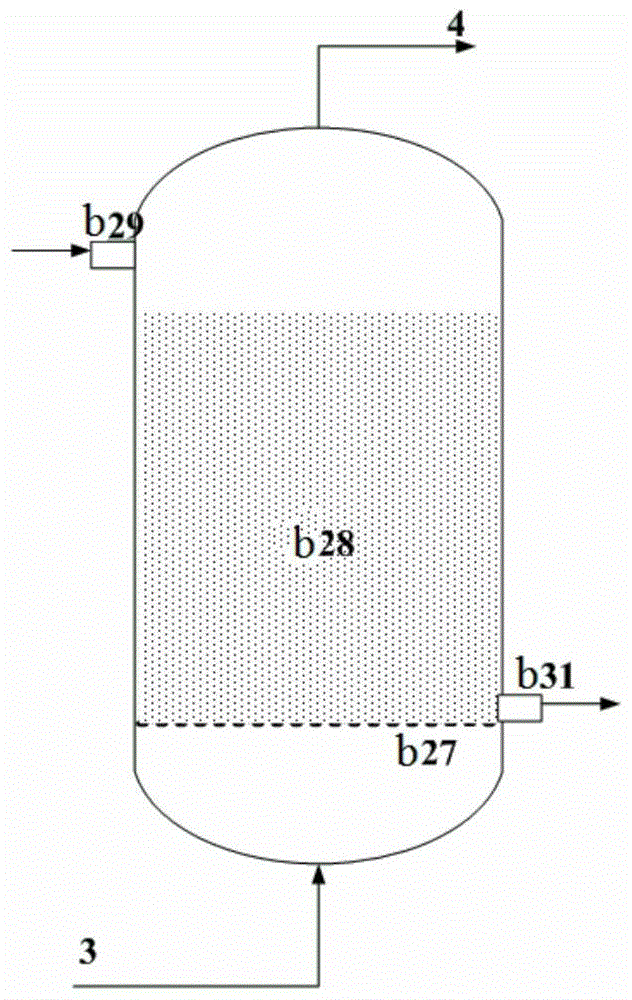

[0050] The raw oil is introduced into the fractionating tower e from the raw oil inlet e1 of the fractionating tower e, and then introduced into the radiation heating zone of the heating furnace a from the bottom of the fractionating tower e for preheating, and the preheated raw oil passes through the raw material The inlet c25 is introduced into the spray coking tower c and atomized through the atomizing nozzle c18 to obtain atomized small droplets of 20-500 μm, and the oxygen-containing high-temperature gas obtained by burning coking dry gas from the combustion chamber of the heating furnace a The gas 3 is deoxidized through the coke reactor b, and the deoxidized high-temperature gas 4 (wherein the oxygen content is 0.1% by volume) is introduced into the spray coking tower c through the hot air inlet c24 at the top of the spray cokin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com