Energy-saving environmental protection coal combustion catalyst

A technology for burning catalysts and coal, which is applied in the direction of fuel, solid fuel, petroleum industry, etc. It can solve problems such as unsatisfactory effects, and achieve the effects of shortening burnout time, improving coking performance, and increasing combustion intensity and furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

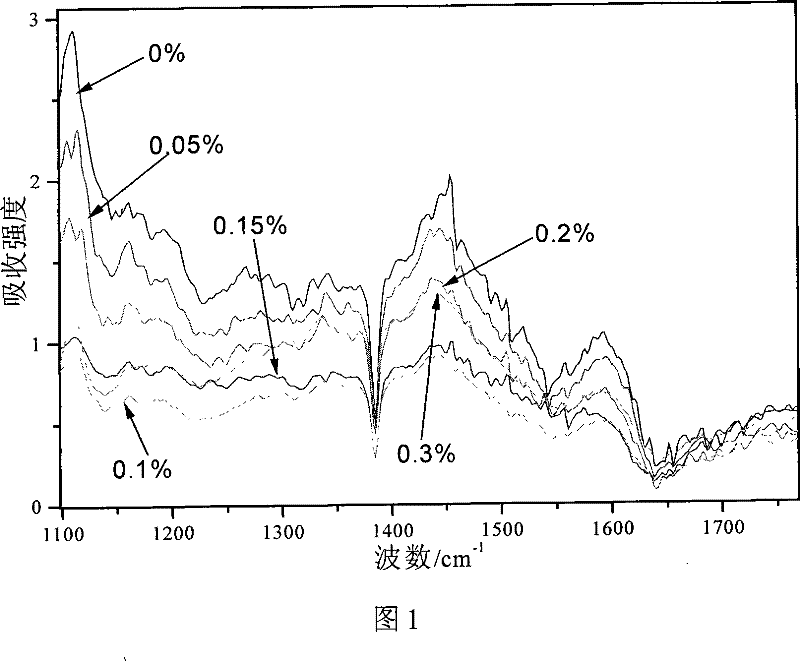

Image

Examples

Embodiment 1

[0020] An energy-saving and environment-friendly coal combustion catalyst is obtained by dissolving the following raw materials in 100 parts of water by mass and filtering them evenly: 25 parts of sulfuric acid factory waste, 30 parts of electroplating factory waste solution, 28 parts of electrolytic copper factory waste solution, 10 parts of nitrated rare earth, Anionic surfactant ammonium lauryl sulfate3 and soluble calcium salt calcium nitrate4.

Embodiment 2

[0022] An energy-saving and environment-friendly coal combustion catalyst is obtained by dissolving the following raw materials in 100 parts of water by mass and filtering them evenly: 30 waste residues from sulfuric acid plants, 28 waste liquids from electroplating plants, 27 waste liquids from electrolytic copper plants, 7 rare earth nitrations, Anionic surfactant ammonium lauryl sulfate4 and soluble calcium salt calcium nitrate4.

Embodiment 3

[0024] An energy-saving and environment-friendly coal combustion catalyst is prepared by dissolving the following raw materials in 100 parts of water by mass and filtering them evenly: 27 waste residues from sulfuric acid plants, 25 waste liquids from electroplating plants, 30 waste liquids from electrolytic copper plants, 8 rare earth nitrates, Anionic surfactant ammonium lauryl sulfate 5 and soluble calcium salt calcium nitrate 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com