A test fixture for a solution-resistant electrochemical material electrode

A test fixture, electrochemical technology, applied in the direction of material electrochemical variables, etc., can solve the problems of high contact resistance between the test material and the lead-out, poor accuracy and stability, and changes in environmental parameters, and it is not easy to change the environmental parameters. , improved stability and reliability, and accurate detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

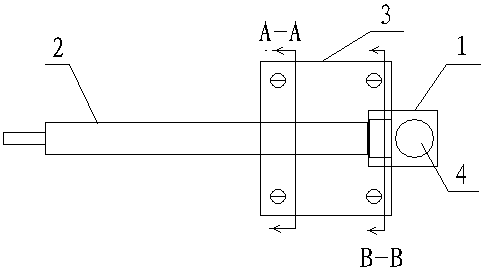

[0025] Such as figure 1 Shown, a kind of test jig of anti-solution corrosion electrochemical material electrode at least includes: test material smear 1, polytetrafluoroethylene Pt sheet electrode 2, fixture 3 and test material 4, fixture 3 test material smear 1 and polytetrafluoroethylene The tetrafluoroethylene Pt sheet electrode 2 keeps the test material smear 1 and the polytetrafluoroethylene Pt sheet electrode 2 electrically connected, and one end of the fixture 3 has the electrode connection end of the polytetrafluoroethylene Pt sheet electrode 2; the other end of the fixture 3 has a test Material 4, Test Material 4 on Test Material Smear 1.

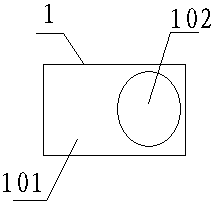

[0026] Such as figure 2 As shown, the main body of the test material smear 1 is glass 102, one side of the glass has a conductive layer 101, and the test material 4 is coated or printed on the conductive layer 101, and the test material smear 1 is rectangular.

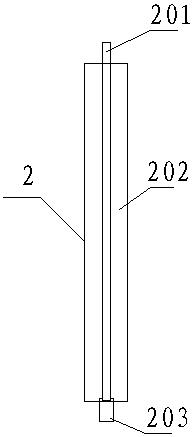

[0027] Such as image 3 As shown, one end of the polytetrafluoroet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com