Phase change heat exchange hot water machine set

A technology of hot water unit and phase change heat, applied in the field of boiler hot water, can solve the problems of boilers prone to corrosion, hydraulic balance imbalance, small heat transfer coefficient, etc., and achieves improved heat transfer coefficient, reasonable structural composition and high thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

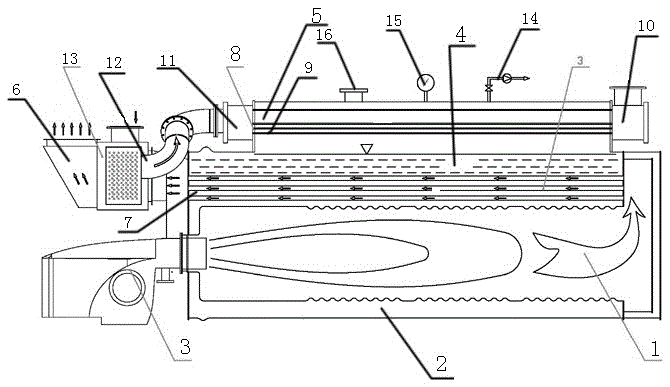

[0015] The invention will be described in detail below in conjunction with the drawings: figure 1 As shown, the phase-change heat and hot water unit of the present invention includes a boiler body 2 with a furnace 1 inside, and a furnace door capable of injecting combustion flames into the furnace 1 is arranged outside the furnace door of the boiler body 2 The combustion engine 3 includes an existing oil or gas engine. The boiler body 2 is also provided with a vacuum chamber 5 filled with heat medium water 4, and a plurality of ends are connected in series in the vacuum chamber 5 The furnace 1, the other end is connected to the flue gas heat exchange tube 7 of the exhaust chimney 6; the upper part of the boiler body 2 is provided with an internal heat exchanger 8 which is heated with the heat medium water in the vacuum chamber 5 to form saturated steam for heat exchange. In the cold water heat exchange channel 9 of the internal heat exchanger 8, the hot water outlet at one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com